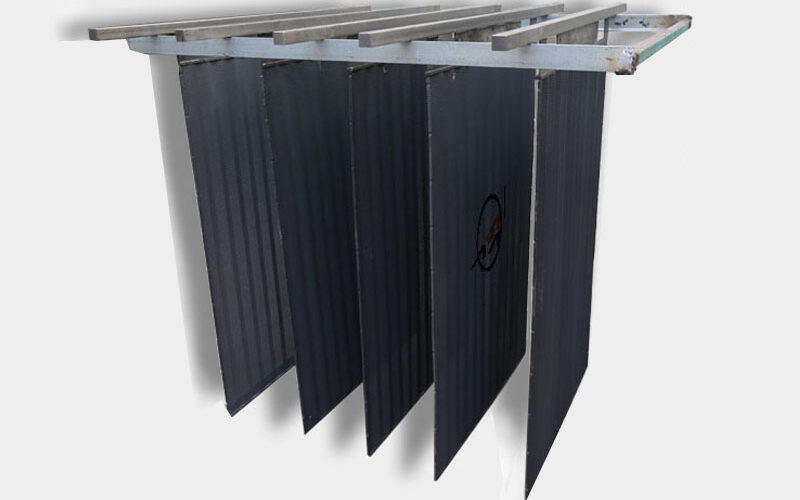

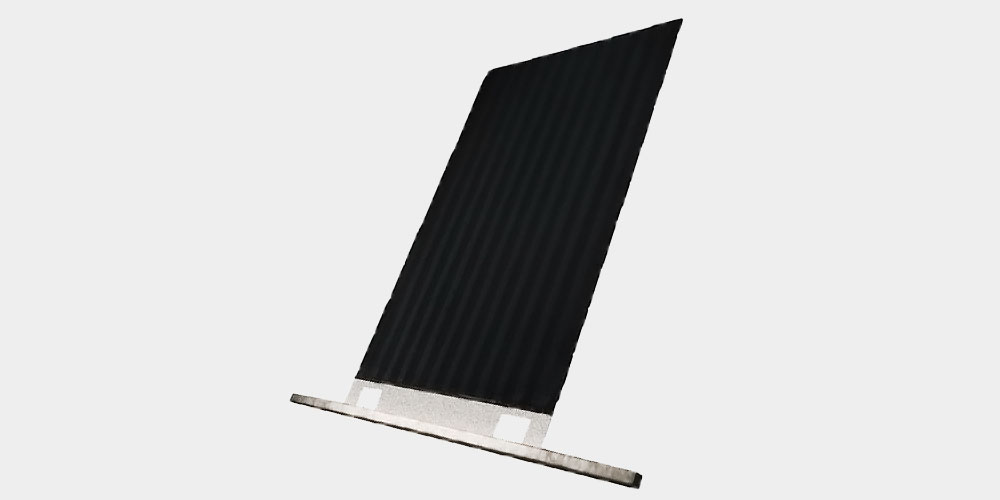

Lead dioxide titanium anode (Ti/PbO2 electrode), which is an electrode material extensively applied in electrochemical water treatment technology and hydrometallurgy.

Composed of a titanium substrate and a lead dioxide (PbO2) active layer, it possesses multiple advantages, such as low resistivity, stable chemical properties, excellent corrosion resistance, good electrical conductivity, and the capacity to conduct large currents.

With the continuous development of the electrochemical industry and anode technology, traditional anode materials in the electrochemical industry have shown their limitations in applications. Especially in the research of anode materials in the oxygen evolution environment, based on our many years of experience in titanium anode manufacturing, we have developed lead dioxide titanium anodes for hydrometallurgy and wastewater treatment.

The lead dioxide titanium anode is processed through the electrodeposition approach. Typically, a layer of α-PbO2 is initially plated on the titanium mesh as the intermediate layer to strengthen the binding force between the substrate and the active layer, minimize the electrode distortion, and subsequently, β-PbO2 is plated as the active surface layer.

The R&D and improvement of lead dioxide titanium anode

Although the lead dioxide titanium anode has the advantages of long service life, good corrosion resistance and large current, the early titanium mesh plated with lead dioxide anode has poor electrical conductivity due to the formation of the passivation layer of the titanium mesh itself, so its electrocatalytic activity is not high, and the mechanical strength of the PbO2 coating is unstable. Therefore, the titanium mesh substrate needs to be modified and processed, that is, by adding a well-conductive intermediate layer and active layer between the titanium mesh and PbO2 to modify the anode substrate to inhibit the formation of the passivation layer, improve the mechanical strength and flexibility of the coating, reduce the internal stress between the substrate and the coating, and improve the stability and electrocatalytic activity of the coating.

What are the advantages of lead dioxide titanium anodes over traditional lead anodes?

- Lead dioxide titanium anode has high strength and is lightweight. It is not prone to deformation during the electrolysis process, and can maintain a relatively stable electrode distance, effectively reducing cell voltage to save electrical energy. At the same time, the electrode works stably, avoiding frequent shutdowns for maintenance and reducing maintenance costs.

- It has strong corrosion resistance, a long service life. During the usage process, the dissolution rate of lead dioxide is low, and the pollution to the cathode products is small.

- The corrosion principles of the lead dioxide titanium anode and the lead anode are distinct. In the sulfuric acid system for the lead anode, a lead oxide film forms on the surface, which can effectively decelerate anode corrosion. Nevertheless, the compactness of this film layer is subpar. Particularly in the electrolyte containing a minute amount of chloride ions, the film layer is prone to being punctured, washed away, and the exposed lead surface keeps oxidizing to form an oxide film, which is punctured again. This cycle repeats, resulting in the continuous corrosion of the lead anode. In contrast, for the lead dioxide titanium anode during operation, it is always the electrochemical corrosion of the lead oxide coating that takes place. Hence, it can maintain a relatively low corrosion rate. The lifespan of the lead dioxide titanium anode can be prolonged by 1.5 to 2 times compared to that of the lead anode.

Application

Water treatment:

It can be used for the treatment of industrial wastewater and domestic sewage. For example, in the removal of organic pollutants, heavy metal ions and other harmful substances in wastewater, it can effectively degrade pollutants through electrochemical oxidation.

It is also applied in the disinfection and sterilization of water.

Electroplating industry:

As the anode in the electroplating process, it provides a stable electrochemical environment to ensure the quality and performance of the coating.

Chemical synthesis:

It is used in some electrochemical synthesis reactions to promote the occurrence of chemical reactions and improve the yield and purity of products.

Metal refining:

In the process of metal refining, it helps to separate and purify metals.

Energy storage field:

It has certain application potential in some energy storage devices.

Why Choose Us?

Unrivaled Product Quality

Crafted from premium titanium with precision and strict quality control, our anodes use advanced coating methods like thermal decomposition. Catalytic layers such as RuO₂-IrO₂ or SnO₂-Sb₂O₃ boost corrosion resistance, electrochemical activity, and lifespan.

Exceptional Performance

With low overpotential, our anodes cut energy use by up to 30% in electrochemical oxidation. High current efficiency enables fast degradation of organic pollutants, heavy metals, and PFAS across various wastewater types.

Customized Solutions

We customize anode coating, thickness, and structure. Our experts analyze your project to ensure cost-effective, optimized performance.

Extensive Industry Experience

Years of work in textiles, pharmaceuticals, and mining give us deep expertise for proactive problem-solving.

Comprehensive Technical Support

Our support covers installation, maintenance, troubleshooting, and staff training.

Sustainable and Environmentally Friendly

Designed to reduce energy use and heavy metal release, our anodes prioritize sustainability, with ongoing R&D for improvements.

Competitive Pricing

Despite top quality, optimized processes and supply chains make our anodes affordable.

Choose us for superior quality, performance, and service. Contact us to achieve your wastewater treatment goals.

Company profile

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

production

1. Substrate treatment: it needs to be treated by roughing, cleaning and removing oil, which can increase the compactness of catalytic.

2. Brushing coating:After substrate treatment, it will be proceeded brush coated. The main coated content is platinum group metal, which is a kind of mixed solution.Then, heat treatment will be going on after drying.The whole procedure need to be repeated many times. This method is better to form thin oxide catalytic that is lamellar adhere to substrate surface.

Quality assurance and after-sales service

1. We promise that our substrate is high quality,acceleratd life test.The coating solution is configured according to the certain proportion.

2. With the high technology and equipment,All of our tecnical personnel have abundant experience,and our workers are very skilled.During the production of the Titanium anode, each process must carry on the strict examination,Such as the detection of surface rougghness,The quality of coating solution,coating evenness and so on.

3. We have our own production,sales and after-service department.We are usually dedicated to provide customers with high quality and reasonable price product.Most importantly ,we can provide the efficient service.

4. Each procedure will be carefully detected in the technical staff to compelete.accomplish the order in time and delivery on time.

5. During our cooperation,if you have any problem ,you can contact us at anytime,we will do our best to help you.