Titanium anode

Here, you will gain a more comprehensive understanding of titanium anodes.

In the 1960s, scholars developed titanium-based oxide-coated electrodes with titanium as the substrate and its surface coated with metal oxides, also known as DSA (Dimensionally Stable Anodes). The coating oxides mainly include RuO2, IrO2, Ta2O5, PbO2, SnO2, etc. After more than 60 years of development, titanium anode have been widely used in industrial fields such as chlor-alkali, chlorate, water electrolysis, sewage treatment, organic synthesis, cathodic protection, and electrolysis.

What is a titanium anode?

Titanium anode, also known as titanium-based metal oxide coated electrode, also called dimensionally stable anode (DSA), is a new type of insoluble anode material developed in the late 1960s. Before that, traditional anode materials such as graphite and lead had many disadvantages. For example, graphite electrodes were prone to wear and tear, and lead electrodes would produce toxic substances during use. With the progress of materials science and electrochemical technology, researchers began to pay attention to the possibility of titanium metal as the anode substrate. Titanium has good corrosion resistance and mechanical strength, laying the foundation for the development of coated titanium anodes.

In the following decades, researchers continuously explored and improved the composition and preparation process of the coating. The main components of the coating are precious metal oxides, such as ruthenium, iridium, platinum, etc. With the in-depth research and the promotion of applications, titanium anodes have gradually replaced traditional platinum, graphite and lead alloy anodes due to their good electrical conductivity, corrosion resistance, mechanical strength and processing performance, as well as long service life. It has gradually become the mainstream and has been widely used.

Titanium anode are mainly applied in the fields of electrochemistry and electrometallurgy, such as chlor-alkali industry, chlorate production, hypochlorite production, perchlorate production, persulfate electrolysis, electrolytic organic synthesis, electrolytic extraction of non-ferrous metals, cathodic protection, copper plating of PCBs, galvanizing of steel plates, etc.

During the development of titanium anode, the metal oxide coating technology has been significantly improved. For example, oxygen evolution type precious metal coated titanium anodes have shown great development potential in the field of non-ferrous metal electrolysis. The research and development of such anodes mainly focus on the modification research of different methods of IrO2-Ta2O5 coatings, aiming to improve their electrocatalytic activity and stability. These studies not only involve the preparation method of the coating, but also include the discussion of the coating failure mechanism.

The research and application of titanium anode have made significant progress in recent years, especially in improving electrocatalytic activity, reducing energy consumption and improving production efficiency. With the continuous advancement of technology, the application prospects of coated titanium anodes will be even broader.

Why choose titanium as anode substrate?

The selection of titanium as the anode substrate is mainly based on the following reasons

- Excellent corrosion resistance:

Titanium can exhibit extremely high corrosion resistance in various chemical environments. Whether it is strong acid, strong alkali or other corrosive media, titanium can remain stable and is not easily corroded and damaged. This enables titanium-based anodes to operate stably under harsher electrochemical working conditions. - Outstanding physical properties: Titanium has high strength and hardness, can withstand the mechanical stress and vibration generated during the electrolysis process, and is not easily deformed or damaged. For example, in large electrolytic cells, titanium anodes can withstand the impact force brought by liquid flow and electrode reactions.

- Low density and light weight: Compared with other metals with similar properties, the density of titanium (4.51) is relatively low, which helps to reduce the overall weight of anode materials, reduce the load and installation and maintenance costs of equipment, and improve efficiency.

- Good processing performance: Titanium has good processability and can be made into various complex shapes and multi-specification-sized anodes to meet the requirements in different electrolytic equipment and processes.

These excellent properties of titanium make it an ideal choice as an anode substrate and can provide stable, efficient and durable anode materials for electrochemical processes.

Why can’t titanium be anode directly?

Copper, iron, aluminum and other metals can be used directly as anodes.

The oxidation reactions of copper, iron, aluminum and stainless steel during the electrolysis process occur relatively easily and can lose electrons under certain conditions to form ions and enter the solution.

In an appropriate electrolyte, the outer electrons of copper atoms are more easily lost, so it can act as an anode to participate in the electrolysis process.

Iron is prone to oxidation under specific circumstances to form iron ions.

Although aluminum usually has an oxide film on the surface, it can also lose electrons under specific conditions.

Due to its composition and structural characteristics, stainless steel can act as an anode in some electrolytic systems.

However, titanium has strong corrosion resistance and chemical stability. Its surface quickly forms a dense and stable oxide film. This oxide film prevents further oxidation and electron loss of titanium, resulting in high resistance and poor conductivity when titanium is used as an anode. Therefore, titanium metal is also called a unidirectional current-carrying valve-type metal during electrolysis.

What is unidirectional valve type metal?

Unidirectional current-carrying valve-type metals, their main characteristic is the obvious directional limitation in current conduction. They are non-conductive when used as anodes but conductive when used as cathodes. This unidirectional conductive property makes them very useful in specific applications, such as in the field of electrochemistry. This characteristic of these metals is due to the difference in electrical conductivity caused by the oxide film formed on their surfaces.

Take titanium as an example. Due to the dense and stable oxide film that is rapidly formed on the surface when positive electricity is applied, the resistivity of this layer of film is very high, resulting in a decrease in the electron transfer rate on the metal surface, thereby showing a non-conductive property. When these metals are used as cathodes, a reduction reaction occurs on their surface. At this time, the metal only acts as a current collector and does not affect the current magnitude of the system. It is like a unidirectional valve for current, only allowing current to flow in a specific direction and playing a significant blocking role for reverse current.

Classification of coated titanium anode

Ru Ir titanium anode

It is an electrode coated with a coating containing precious metal oxides such as ruthenium and iridium on the surface of the titanium substrate. This coating can significantly improve the chlorine evolution performance of the titanium anode.

Ir Ta titanium anode

It is typically made with titanium metal as the base material, and its surface is coated with iridium dioxide and tantalum oxide coatings. It is mainly utilized in the oxygen evolution environment of the electrochemical industry.

Pt titanium anode

Platinum-plated titanium anode is an electrode material plated with a platinum layer on the surface of titanium metal. The platinum-plated titanium anode can ensure a stable electrolysis process and thereby obtain high-quality products.

Titanium anode production process and procedure

The processing process of titanium anode mainly includes the following steps:

-

- Choice of material: titanium anode substrate is generally Gr1 material, according to the drawings to select the corresponding profiles, plate, rod, wire, tube, belt, net, etc.

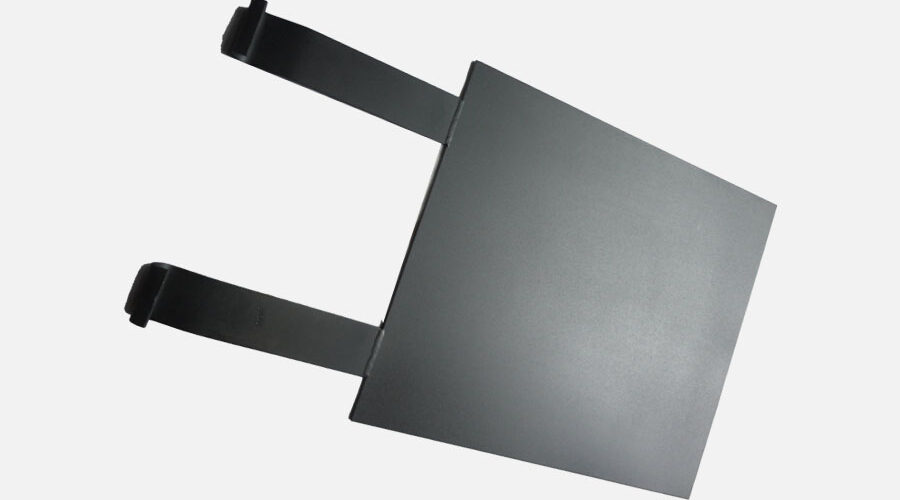

- Processing and forming: according to the required titanium anode size and shape, for the selected profile sheet metal and mechanical processing.

- Welding process: welding of the finished titanium material, by argon arc welding, resistance welding or arc welding methods, to ensure the fastness and mechanical strength of the welding parts.

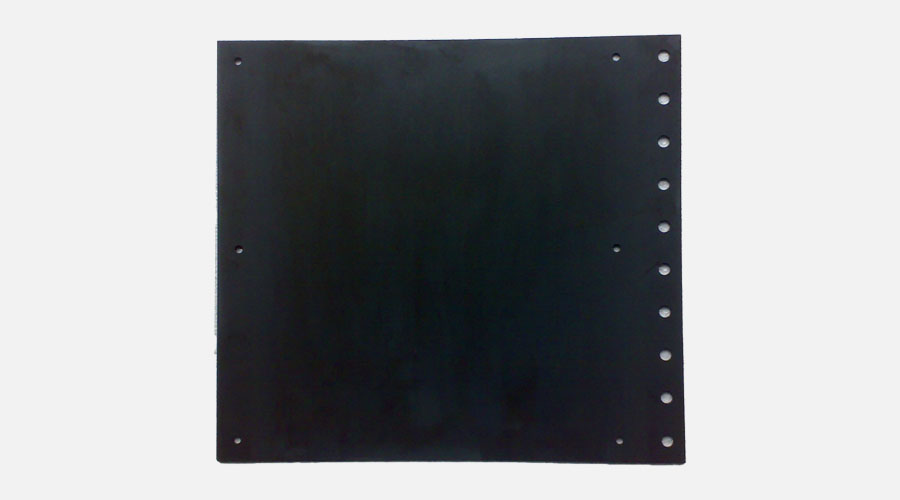

- Roughening treatment: The processed substrate is sandblasted or corroded with acid to increase the binding force between the substrate and the coating and increase the real specific surface area of the anode.

- Relatively flat annealing: after machining and sandblasting treatment, the substrate will be deformed due to processing stress. High temperature annealing can eliminate the internal stress of the product and make the material more flat.

- Pickling and boiling material: after annealing, a dense layer of titanium dioxide will be formed on the surface of the product. Before coating, the oxide layer should be removed by boiling material, and the base material should be placed in the oxalic acid tank for boiling. Oxalic acid can not only effectively remove the blue oxide on the substrate during annealing, but also make the surface roughness of the substrate more uniform through corrosion.

- Coating liquid: According to different industries and requirements, the different content of precious metal coating liquid, liquid should pay attention to the proportion and order of the addition of raw materials.

- Coating processing: The prepared coating liquid is evenly coated on the surface of the substrate, and after drying, it is sintered. This process needs to be repeated 18 to 22 times to make the product meet the corresponding industry requirements and precious metal content.

- Product inspection: anode quality inspection, appearance quality, uniformity, porosity, strengthening life, to ensure that the anode quality meet the requirements of industry and related standards.

- Packing: The anodes with qualified quality shall be packed. During the packing process, shall be protected against the anode surface and shall be avoided from scratching and damage.

Application fields of titanium anode

Common application industries of titanium anode

Titanium anode for electrochemical industry

Chlor-alkali industry

Titanium anode is widely used in the production of caustic soda by the traditional diaphragm method and the ion-exchange membrane method. It is resistant to the corrosion of chlorine gas and alkali liquor. Compared with graphite anode, its service life increases significantly (the service life of graphite anode is generally 8 months, while that of titanium anode can reach more than 6 years). It can work at a high current density to improve production efficiency. Due to the fine bubbles generated on its surface and their rapid detachment, the resistance between electrodes and the cell voltage are reduced. It avoids the pollution of the electrolyte and cathode products and improves the purity of chlorine gas and the concentration of alkali liquor, etc.

Hydrometallurgy

Electrolytic extraction of non-ferrous metals such as copper and nickel.

Titanium anodes can remain stable in a relatively harsh electrolyte environment, overcome the problem that some traditional electrode materials are prone to corrosion and dissolution, can be reused multiple times, and reduce production costs; improve current efficiency and the purity of the extracted metals, and do not cause secondary pollution to the products.

Electroplating industry

As an insoluble anode in various electroplating processes (such as nickel plating, gold plating, chromium plating, zinc plating, copper plating, etc.).

Its surface has a coating of precious metal oxides with high electrochemical catalytic performance. The oxygen evolution overpotential is lower than that of traditional lead alloy insoluble anodes, which is energy-saving and highly stable, and does not contaminate the plating solution; it can reduce the cell voltage and save power consumption under the same conditions; it has good chemical and electrochemical stability during the electroplating process.

Electrolytic copper foil

In the production of electrolytic copper foil, the titanium anode can operate stably in the electrolytic solution, provide a uniform current distribution, and contribute to the formation of electrolytic copper foil with uniform thickness, smooth surface and excellent performance

Sewage treatment field

Industrial wastewater treatment (such as cyanide-containing wastewater in electroplating plants, etc.)

It can carry out redox reactions on heavy metal ions and other substances in wastewater to make them form precipitates or transform into harmless substances; use the strongly oxidizing substances such as hypochlorite generated by it to decompose organic pollutants, etc.

Sewage treatment field

- Industrial wastewater treatment (such as cyanide-containing wastewater in electroplating plants, etc.)

It can carry out redox reactions on heavy metal ions and other substances in wastewater to make them form precipitates or transform into harmless substances; use the strongly oxidizing substances such as hypochlorite generated by it to decompose organic pollutants, etc. - Hospital sewage treatment

It can kill microorganisms such as pathogens in hospital sewage; it can effectively purify the sewage.

Aluminum foil formation

During the aluminum foil formation process, titanium anode is helpful to improve the formation effect and enhance the performance of the aluminum foil. It can work stably in the specific electrolyte, providing suitable electrochemical conditions for the formation reaction, enabling the formation of a uniform and dense oxide film on the surface of the aluminum foil, thereby enhancing the corrosion resistance, insulation and other properties of the aluminum foil.

Environmental protection

- Disinfection of swimming pool water and domestic water

Introduction: Utilizing its electrochemical characteristics to generate disinfection components, such as hypochlorous acid in water, for the disinfection and purification treatment of domestic water to ensure the safety of domestic water; when used for the disinfection of food utensils, it can avoid the problems of chemical residues brought by traditional disinfection methods. - Treatment of cooling circulating water

Effectively control the growth of microorganisms and algae in the cooling circulating water, reduce scaling and corrosion, ensure the efficient and stable operation of the cooling circulating water system, and reduce the discharge of high-salinity water. - Degradation of organic wastewate

Oxidative degradation of organic pollutants such as dyes and auxiliaries in dyeing and finishing wastewater to reduce indicators such as chemical oxygen demand (COD) and biochemical oxygen demand (BOD) of the wastewater.

Electrolytic organic synthesis.

It serves as an electrode in organic synthesis to provide a specific electrochemical environment, promoting reactions to proceed in a more efficient, green, and controllable manner, and can reduce side reactions, etc.

Cathodic protection

As an auxiliary anode, it forms a circuit with the protected metal structure to provide electrons to the protected metal, keeping the protected metal at a relatively stable potential and avoiding or reducing corrosion.

Electrolytic hydrogen production

As an efficient electrode material, it promotes the water electrolysis reaction and improves the production efficiency and purity of hydrogen.

Electrolytic phosphating

Through electrolysis, the components in the phosphating solution undergo a chemical reaction on the metal surface to form a layer of phosphating film. This layer of phosphating film usually has good corrosion resistance, wear resistance and adhesion, which can improve the protective performance and coating effect of the metal surface.

Energy storage battery

The energy storage battery is capable of storing electrical energy in the form of chemical energy and releasing the stored energy for use when needed.

Common types of energy storage batteries include lithium-ion batteries, lead-acid batteries, flow batteries, etc.

Titanium anode are applied in flow batteries and can be used for large-scale and long-term energy storage needs, such as energy storage support for large-scale wind farms and solar power stations.

Return to the contents

- The history of titanium anode

- What is a titanium anode?

- Why choose titanium as anode substrate?

- Why can’t titanium be anode directly?

- What is unidirectional valve type metal?

- Classification of coated titanium anode

- Titanium anode production process and procedure

- Application fields of titanium anode

- Why choose our titanium anodes?

- Why choose our titanium anodes?

Why choose us?

Our products have stable quality, excellent performance and a high degree of customization.

Professional R & D team:After 18 years of development, we have cultivated and attracted a group of experienced and technically proficient R & D talents who have an in-depth understanding of titanium anodes from materials science to electrochemical principles. We constantly optimize the performance of existing products, such as improving current efficiency, reducing energy consumption, and extending service life.

Coated titanium anode

recautions for the use of titanium anode

Proper maintenance of the coated titanium anode can improve the electrolysis efficiency and extend the service life.

- Installation and Connection

When installing, ensure a firm and reliable connection between the electrode and the power supply to avoid poor contact that leads to increased resistance and local overheating.

For example, when connecting wires, ensure a sufficient contact area and use appropriate fastening screws.

Avoid causing mechanical damage to the electrode surface during the installation process to prevent affecting the integrity of the coating.

For instance, it is strictly prohibited to touch the coating surface with sharp tools. - Electrolyte Environment

The appropriate electrolyte composition and concentration should be selected according to the specific electrolysis process and requirements.

For example, in some cases, an excessively high acid concentration may accelerate the corrosion of the coating.

Control the impurity content in the electrolyte, especially the impurities that are harmful to the coating, such as fluoride ions, etc.

Taking the electrolyte containing fluoride ions as an example, a trace amount of fluoride ions may cause severe damage to the coating. - Working Current and Voltage

Operate strictly in accordance with the designed current density and voltage range to avoid overcurrent or overvoltage.

Exceeding the allowable current density may cause the coating to overheat and peel off, while an excessively high voltage may increase electrolytic side reactions.

During the electrolysis process, the current and voltage should rise and fall smoothly. When starting or stopping the machine, sudden and significant fluctuations should be avoided. - Electrolysis Temperature Control

Pay attention to the temperature changes during the electrolysis process. Excessive temperature will affect the electrocatalytic activity and electrolysis efficiency of the coating. When working in an environment with a high electrolyte temperature, heat exchange equipment needs to be added to the electrolytic cell to ensure a normal electrolysis temperature.

During electrolysis, sharp temperature changes should be avoided, as this will cause thermal stress between the precious metal coating and the titanium substrate, reducing the binding force between the coating and the substrate and shortening the anode’s service life. - Regular Inspection and Maintenance

Regularly inspect the appearance of the coating on the surface of the titanium anode to observe whether there are abnormal phenomena such as coating peeling or scratching.

If minor damage to the coating is found, it should be repaired or replaced in time to avoid oxidation and corrosion at the missing parts of the anode coating.

Regularly clean the attachments on the anode surface to prevent them from affecting the conductive performance of the electrode. - Storage of Titanium Anode

When the titanium anode is not in use during shutdown, it should be removed from the equipment, rinsed clean, and stored in a dry and well-ventilated environment. Avoid storing it in a damp place or one with corrosive gases.

During storage, be careful to prevent the titanium anode from mechanical impact and physical scratching to avoid damage to the coating surface.

Contact us

R&D

R&D has always been the basis for the sustainable development of modern enterprises. Only by attaching importance to and strengthening the R&D of titanium anode coatings can enterprises achieve long-term and stable development in today’s highly competitive business environment.