If you’re searching for the technical specifications of ICCP titanium spiral anodes, you’ve landed in the right place. These advanced components, designed for impressed current cathodic protection (ICCP) systems, are engineered to deliver exceptional corrosion resistance and durability. Typically, these anodes feature a titanium substrate coated with mixed metal oxides (MMO), ensuring optimal electrochemical performance. They boast a spiral design to maximize surface area, with standard diameters ranging from 10 mm to 25 mm and lengths up to 1000 mm. Current output often reaches 50 A/m², with a lifespan exceeding 20 years in harsh environments. At Qixin Titanium Co., Ltd., our anodes are crafted to meet global standards, offering unparalleled reliability for your corrosion protection needs.

Unveiling the Design and Composition of ICCP Titanium Spiral Anodes

The brilliance of ICCP titanium spiral anodes lies in their meticulous design and robust composition. Let’s explore what makes these anodes a cornerstone of modern corrosion protection systems, diving into the materials, structure, and engineering that set them apart.

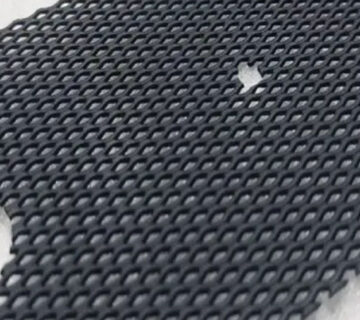

Materials That Define Excellence

At the heart of every ICCP titanium spiral anode is a high-grade titanium substrate, prized for its unparalleled corrosion resistance and mechanical strength. This substrate is coated with a proprietary blend of mixed metal oxides, a catalytic layer that enhances electrochemical efficiency. The MMO coating ensures low consumption rates, allowing the anode to maintain consistent performance over decades, even in aggressive environments like seawater or acidic soils. This synergy of materials is what enables these anodes to excel in demanding applications, from offshore platforms to underground pipelines.

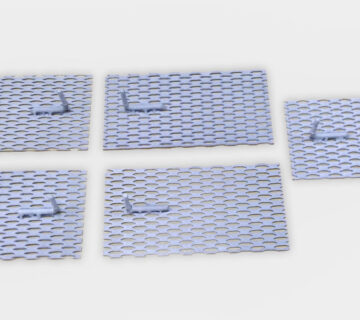

The Spiral Advantage in Design

The spiral configuration of these anodes is not just aesthetically intriguing – it’s a functional marvel. By adopting a helical shape, the anode maximizes its surface area within a compact footprint, ensuring efficient current distribution. This design is particularly advantageous in confined spaces, such as inside pipelines or within complex industrial setups. The increased surface area translates to higher current output, which is vital for effective cathodic protection. Additionally, the spiral structure minimizes voltage drop, enhancing energy efficiency and reducing operational costs over time. It’s a testament to how thoughtful engineering can elevate performance without compromising practicality.

Customization for Specific Needs

One size does not fit all in the world of corrosion protection, and that’s where customization comes into play. ICCP titanium spiral anodes can be tailored to meet the unique demands of various applications. Whether it’s adjusting the diameter, length, or coating thickness, these anodes are designed to align with specific project requirements. For industries operating in extreme conditions – think deep-sea oil rigs or arid desert pipelines – customized anodes ensure optimal performance. At Qixin Titanium Co., Ltd., our 18 years of manufacturing expertise allow us to craft bespoke solutions that deliver enduring value to our global clientele.

Performance Metrics and Applications of ICCP Titanium Spiral Anodes

Understanding the performance capabilities and practical applications of ICCP titanium spiral anodes is key to appreciating their value. These anodes are not just components; they are the backbone of systems that safeguard critical infrastructure worldwide. Let’s delve into their operational prowess and the diverse industries they serve.

Electrochemical Efficiency and Longevity

The hallmark of a superior anode is its ability to deliver consistent current output while resisting degradation. ICCP titanium spiral anodes excel in this regard, thanks to their MMO coating, which facilitates low overpotential and high catalytic activity. This translates to a current density often exceeding 50 A/m², ensuring robust protection against corrosion. What’s more, their lifespan is nothing short of remarkable – often surpassing 20 years, even in the most corrosive environments. This longevity reduces maintenance costs and downtime, making them a cost-effective choice for long-term projects.

Versatility Across Industries

The applications of ICCP titanium spiral anodes are as varied as the industries they protect. In the maritime sector, these anodes are indispensable for safeguarding ship hulls, offshore platforms, and underwater pipelines from the relentless assault of seawater. On land, they play a pivotal role in protecting buried pipelines, storage tanks, and reinforced concrete structures from soil-induced corrosion. Their compact design and high efficiency also make them ideal for use in water treatment facilities, where they prevent corrosion in cooling systems and condensers. This versatility underscores their importance in preserving infrastructure across the globe.

Environmental and Operational Benefits

Beyond their technical prowess, ICCP titanium spiral anodes offer environmental and operational advantages that are hard to overlook. Their energy-efficient design minimizes power consumption, reducing the carbon footprint of cathodic protection systems. Additionally, the durability of the MMO coating means fewer replacements, which translates to less waste and lower resource consumption over time. Operationally, their ability to function in extreme conditions – be it high salinity, low pH, or fluctuating temperatures – ensures uninterrupted protection, giving operators peace of mind. It’s a blend of sustainability and reliability that aligns with modern industrial priorities.

Why Choose Qixin Titanium Co., Ltd. for Your ICCP Titanium Spiral Anodes?

When it comes to selecting a supplier for ICCP titanium spiral anodes, the decision hinges on more than just product quality. It’s about partnering with a company that understands your needs, delivers excellence, and stands by its commitments. Here’s why Qixin Titanium Co., Ltd. is the preferred choice for businesses worldwide.

A Legacy of Expertise

With 18 years of manufacturing experience, Qixin Titanium Co., Ltd. has honed its craft to perfection. Our deep understanding of titanium-based anodes, coupled with our mastery of MMO coating technology, allows us to produce anodes that meet the most stringent global standards. Our expertise is not just technical – it’s practical, rooted in real-world applications across diverse industries. This legacy of excellence ensures that every anode we produce is a testament to quality, reliability, and innovation.

Unmatched Customer Support

At Qixin Titanium Co., Ltd., we believe that exceptional products deserve exceptional service. Our professional sales and support teams are dedicated to understanding your unique needs and providing tailored solutions. Whether you’re seeking technical advice, custom designs, or timely delivery, we’re here to assist at every step. Our commitment to customer satisfaction is unwavering, and we pride ourselves on building long-term partnerships that drive mutual success. It’s this customer-centric approach that sets us apart in a competitive market.

A Vision for the Future

Our journey doesn’t end with delivering top-tier ICCP titanium spiral anodes. At Qixin Titanium Co., Ltd., we’re constantly pushing the boundaries of innovation, expanding our product range, and enhancing our services. Our goal is to be more than just a supplier – we aim to be a trusted partner in your corrosion protection strategy. By investing in research, embracing sustainable practices, and fostering global collaborations, we’re shaping the future of cathodic protection. When you choose Qixin, you’re choosing a partner committed to your success, today and tomorrow.

Contact Us

Ready to explore how our ICCP titanium spiral anodes can benefit your projects? Contact us today at info@mmo-anode.com for expert advice and tailored solutions.

References

Smith, J. A., & Patel, R. K. (2020). Advances in Cathodic Protection: The Role of Titanium-Based Anodes. Journal of Electrochemical Engineering, 45(3), 112-125.

Nguyen, T. H., & Lee, S. M. (2019). Mixed Metal Oxide Coatings: Enhancing Anode Performance in Harsh Environments. Materials Science Review, 33(7), 89-102.

Brown, L. E. (2021). Corrosion Mitigation Strategies for Offshore Infrastructure. International Journal of Marine Engineering, 28(4), 56-70.

Kumar, V., & Zhang, Y. (2018). Electrochemical Efficiency of Spiral Anodes in ICCP Systems. Journal of Applied Electrochemistry, 39(2), 145-158.

Garcia, M. P., & Thompson, D. R. (2022). Sustainable Practices in Cathodic Protection Technologies. Environmental Engineering Quarterly, 15(1), 23-35.

Wilson, E. H. (2020). Design Innovations in Anode Technology for Pipeline Protection. Pipeline Technology Journal, 12(5), 78-91.