What are Ru Ir Titanium Anode?

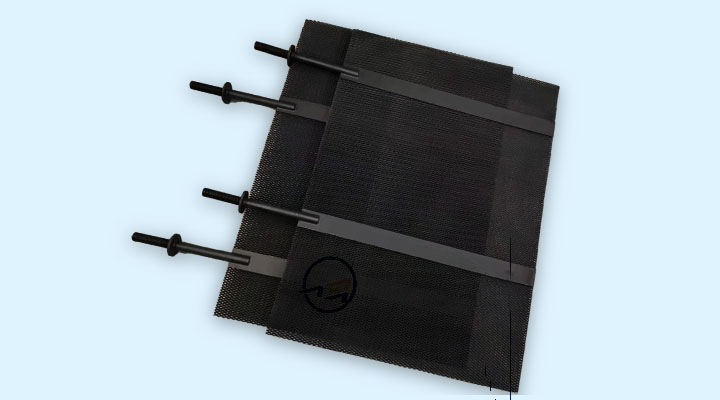

Ru Ir titanium anode are electrodes composed of a titanium substrate with a coating of a mixture of ruthenium and iridium, two precious metals known for their exceptional electrochemical properties.

This coating is applied to the titanium surface through advanced techniques such as sputtering or thermal decomposition, creating a robust and electrocatalytically active layer.

Ruthenium-Iridium-Titanium anode

Ruthenium Iridium Titanium anode is their high efficiency in electrochemical processes such as electrolysis and electroplating.

They can significantly reduce energy consumption and increase the productivity of these operations.

For example, in the electrolysis of water to produce hydrogen, these anodes enable a faster and more efficient conversion process.

In addition, their corrosion resistance is a key feature that sets them apart. They can withstand aggressive chemical environments and prolonged exposure to electrolytes without significant degradation.

This makes them suitable for applications in industries such as chemical manufacturing and wastewater treatment.

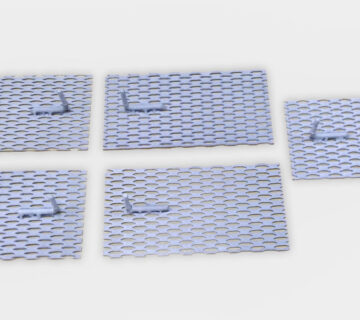

Ruthenium Iridium Titanium anode can also be tailored by adjusting the composition and microstructure of the alloy.

This allows for customization to meet the specific requirements of different electrochemical systems.

Applications of Ruthenium-Iridium Coated Titanium Anode

Ru Ir titanium anode have revolutionized various industrial processes due to their exceptional electrochemical properties.

The combination of ruthenium, iridium, and titanium offers a unique set of characteristics that make these anodes indispensable in several applications.

-

- Chlorine Production

One of the primary applications of ruthenium-iridium coated titanium anodes is in the chlor-alkali industry.

These anodes are used in the membrane cell process for the production of chlorine and sodium hydroxide.

The high electrochemical efficiency and stability of the anodes ensure a continuous and reliable supply of chlorine, which is crucial for applications in water treatment, pulp and paper, and chemical manufacturing. - Electroplating

In the electroplating industry, ruthenium-iridium coated titanium anode are employed for depositing a variety of metals onto substrates.

The anode ability to withstand high current densities without degradation makes them ideal for achieving uniform and high-quality metal coatings.

They are used in plating processes for metals such as copper, nickel, gold, and chromium, which are essential for decorative and functional applications in automotive, electronics, and jewelry industries.

- Chlorine Production

Water Treatment

The water treatment sector benefits significantly from ruthenium-iridium coated titanium anode.

These anodes are used in electrochlorination systems to produce sodium hypochlorite, a powerful disinfectant used to treat drinking water and industrial wastewater.

Additionally, they are used in the electrocoagulation process to remove pollutants and heavy metals from water, contributing to environmental protection and the conservation of water resources.

- Electrowinning

The extractive metallurgy industry utilizes ruthenium-iridium coated titanium anode for the electrowinning of metals such as copper, gold, and nickel from their ores or solutions.

The anode high efficiency and resistance to corrosion allow for the effective and economic extraction of these metals, which are vital for various industrial applications.

The applications of ruthenium-iridium coated titanium anodes span across multiple industries, showcasing their versatility and importance in modern electrochemical processes.

Their contribution to chlorine production, electroplating, water treatment, metal finishing, electrowinning, and oxygen generation is a testament to their reliability and efficiency.

As the demand for sustainable and high-performance technologies continues to grow, the role of Ru Ir titanium anode is expected to expand.

Who we are?

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

Production

Brush coating.

Specific operation as follows:

Firstly,making the coating solution according to the type and the area of the platinum electrode; secondly ,put the solution on the surface evenly, then put them into the drying furance for drying; thirdly,we need to oxidate in the high temperature oxidation furance;Lastly, dry it to room temperature. Then,repeat these steps until you run out the configuration solution.

Certification

Qixin is ISO 9001:2015 certified and own more than 10 patents. All its processes and procedures are documented and controlled in accordance with these standard. Qixin has strict product quality control procedure, from raw material to finished product, all the process is tested qualified to assure high quality product.

With technical engineers experienced for more than 18 years of constant research and production for titanium electrode and its application in various industries, Qixin can offer a very high level of technical support and products, which are among its most remarkable characteristics.

FAQ

1. How to ensure the product quality?

All products make 100% inspection before shipment also we can provide the MTC Material Test Certification.

2. Can you print our Logo on the products?

Sure, and we welcome the customerized products.

3.What about the payment terms?.

T/T, L/C, Paypal, Western Union, Escrew and MoneyGram etc are all accepted.

4.What is the necessary information for an inquiry?

Product name, specification, material grade and quantity.

5.Can we get a free sample before cargo production?

Sure.