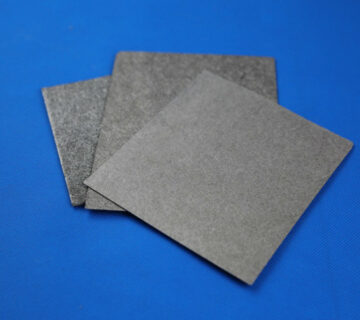

Titanium powder sintered porous metal filters are advanced filtration elements manufactured by sintering high-purity titanium powder under controlled conditions. This process forms a three-dimensional, interconnected porous network that integrates titanium’s inherent chemical stability with the permeability of porous materials. Widely recognized for their durability, precision, and resistance to harsh environments, these filters are indispensable in industries requiring high-performance separation—from water treatment to aerospace.

| Indicator | Typical Range | Industrial Significance |

|---|---|---|

| Pore Size | 0.1μm – 200μm | Defines filtration accuracy: – 0.1–0.22μm: Removes bacteria, viruses, and colloids (pharmaceutical/electronics). – 1–10μm: Filters suspended solids, algae (water treatment). – 50–200μm: Separates large particles (industrial pre-filtration). |

| Porosity | 30% – 60% | Balances flux and strength: – Higher porosity (50–60%): Larger water/gas flux (low resistance) but lower mechanical strength. – Lower porosity (30–40%): Higher compressive strength (for high-pressure systems) but reduced flux. |

| Permeability | 1–50 m³/(m²·h·kPa) | Measures the rate of fluid/gas passing through the filter. Critical for high-throughput applications (e.g., industrial wastewater treatment). |

| Corrosion Resistance | Resistant to pH 1–14 (acids/alkalis) and oxidizing media (chlorine, ozone) | Enables use in harsh environments: – Seawater (high salt content). – Acidic wastewater (electroplating, pickling). – Pharmaceutical sterilization (ozone/chlorine disinfection). |

| Mechanical Strength | Compressive strength: ≥80MPa; Tensile strength: ≥20MPa | Ensures structural stability: No deformation/cracking under high pressure (e.g., 1–5MPa in industrial pipelines) or thermal shock. |

| Operating Temperature | -200℃ – 300℃ (continuous); Up to 600℃ (short-term) | Suitable for extreme temperature scenarios: – Low-temperature: Cryogenic fluid filtration (LNG). – High-temperature: Hot gas purification (power plants) or steam sterilization (pharmaceuticals). |

Advantages Over Traditional Filters

Compared to conventional filters (PP cotton, activated carbon, ceramic, or polymer membranes), titanium powder sintered porous metal filters offer irreplaceable benefits:

No Secondary Pollution

Titanium is biochemically inert (no dissolution of heavy metals, plasticizers, or binders into the filtered medium).

The sintered structure is monolithic (no loose particles), meeting strict hygiene standards for food, pharmaceuticals (GMP compliance), and drinking water.

Exceptional Durability & Reusability

Unlike disposable PP/ceramic filters (service life: 1–3 months), titanium filters can be reused for 2–8 years (depending on application).

Broad Environmental Adaptability

Resists corrosion from seawater, acids (hydrochloric acid, sulfuric acid), alkalis (sodium hydroxide), and oxidants (chlorine, hydrogen peroxide)—a capability unmatched by stainless steel (corrodes in strong acids) or polymer membranes (swell in organics).

Withstands extreme temperatures (from cryogenic to high-heat) and pressure shocks, making it suitable for both indoor and outdoor (e.g., marine) applications.

Customizable Design

Sheet filters: Used for plate-and-frame filtration systems (food processing).

Tubular/cartridge filters: For pipeline filtration (water treatment, oil & gas).

Multi-channel filters: High-flux designs for large-scale industrial processes (power plant cooling water).

Application Fields

Titanium powder sintered porous metal filters are used in industries requiring high filtration performance, chemical stability, and reliability. Key applications include:

Water & Wastewater Treatment

Drinking Water/Mineral Water: Precision filtration to remove rust, sediment, bacteria (≥0.22μm), and colloids; used as pre-filters for reverse osmosis (RO) systems.

Seawater Desalination: Pre-filtration to remove algae, suspended solids, and sand, protecting RO membranes from fouling.

Industrial Wastewater: Filtration of acidic/alkaline wastewater (e.g., electroplating, pharmaceutical, textile) and recovery of valuable solids (e.g., catalyst particles, metal oxides).

Pharmaceutical & Biomedical

Injection Water/Purified Water: Sterile filtration (0.22μm) compliant with GMP standards; can be steam-sterilized (121℃) repeatedly without deformation.

Bioprocessing: Filtration of cell cultures, vaccines, and biopharmaceuticals (biocompatible, no adsorption of active ingredients).

Food & Beverage

Beverage Filtration: Clarification of wine, beer, fruit juice, and dairy products (removes yeast, bacteria, and pulp without affecting taste).

Edible Oil Processing: Filtration to remove impurities, free fatty acids, and particulate matter, improving oil quality and shelf life.

Chemical & Petrochemical

Catalyst Recovery: Filtration and recycling of solid catalysts (e.g., in petrochemical cracking processes) to reduce material waste.

Gas Purification: Filtration of process gases (e.g., hydrogen, nitrogen) to remove dust, oil mist, and liquid droplets.

Company Profile

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

production

1. Substrate treatment: it needs to be treated by roughing, cleaning and removing oil, which can increase the compactness of catalytic.

2. Brushing coating:After substrate treatment, it will be proceeded brush coated. The main coated content is platinum group metal, which is a kind of mixed solution.Then, heat treatment will be going on after drying.The whole procedure need to be repeated many times. This method is better to form thin oxide catalytic that is lamellar adhere to substrate surface.

Why choose us?

1. Superior Material Quality & Durability

Corrosion Resistance: Titanium’s inherent resistance to acids, alkalis, and chloride-rich environments ensures long service life in demanding applications like cobalt electrowinning or wastewater treatment.

High Strength & Stability: Titanium maintains structural integrity under high currents and temperatures, reducing the risk of deformation or degradation.

Customized Coatings: We apply advanced oxide coatings (e.g., ruthenium, iridium, platinum group metals) tailored to your process, enhancing conductivity, catalytic activity, and longevity.

2. Technical Expertise & Custom Solutions

Tailored Design: We analyze your process parameters (current density, electrolyte composition, temperature) to design anodes that maximize efficiency.

R&D-Driven Innovation: Our team stays ahead of industry trends, integrating the latest coating technologies (e.g., mixed metal oxides, dimensionally stable anodes – DSAs) for performance gains.

Testing & Validation: Pre-production prototypes undergo rigorous testing to ensure compliance with your specifications.

3. Cost-Effectiveness & Sustainability

Lower Total Cost of Ownership (TCO):

Longevity reduces replacement frequency compared to traditional anodes (e.g., lead, graphite).

Energy-efficient designs cut electricity costs in large-scale operations.

Eco-Friendly: Titanium is recyclable, and our coatings minimize metal leaching, aligning with environmental regulations.

4. Reliable Service & Support

Global Supply Chain: Timely delivery through the streamlined manufacturing and logistics network.

Technical Support: Post-installation guidance, troubleshooting, and maintenance recommendations.

Compliance Assurance: Anodes meet international standards (e.g., ISO, SGS) and can be certified for specific industries (e.g., mining, water treatment).

FAQ

1. How to ensure the product quality?

All products make 100% inspection before shipment also we can provide the MTC Material Test Certification.

2. Can you print our Logo on the products?

Sure, and we welcome the customerized products.

3.What about the payment terms?.

T/T, L/C, Paypal, Western Union, Escrew and MoneyGram etc are all accepted.

4.What is the necessary information for an inquiry?

Product name, specification, material grade and quantity.

5.Can we get a free sample before cargo production?

Sure.