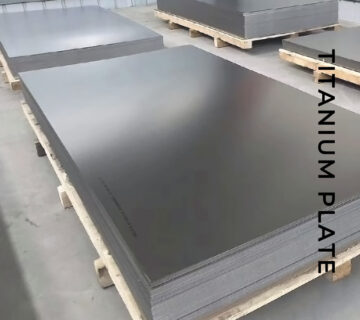

Titanium mesh with excellent corrosion resistance to replace the traditional applicable materials, such as nickel-free stainless steel mesh, aluminum mesh and other metal materials, titanium mesh plate long service life, safe and reliable.

The corrosion resistance of titanium mesh

In the corrosion-resistant medium environment, the surface of the titanium mesh plate generates a dense, strong adhesion, inert oxide film, resulting in passivation phenomenon, protecting the titanium mesh matrix from corrosion, so as to achieve strong corrosion resistance; Especially in the following use of the environment more excellent corrosion resistance, such as: seawater, wet chlorine gas, chlorite and hypochlorite solution, nitric acid, chromate metal chloride and organic salts, etc. (for example: 60% nitric acid, pure titanium wire mesh in nitric acid solution corrosion rate is only 0.001mm.a-1).

Factors affecting corrosion resistance of titanium mesh

- Chemical Composition of the Environment: The types and concentrations of chemicals present in the surrounding medium play a crucial role. Strong acids, alkalis, and certain aggressive ions can potentially affect its corrosion resistance.

For example, highly concentrated sulfuric acid or hydrofluoric acid may have a more significant impact. - Temperature: Elevated temperatures can accelerate chemical reactions and increase the corrosive effect on the titanium mesh.

- Surface Condition: Any damage, scratches, or impurities on the surface of the titanium mesh can compromise its protective oxide layer, reducing its corrosion resistance.

- Oxygen Availability: Sufficient oxygen is necessary for the formation and maintenance of the passive oxide film that provides corrosion protection.

In oxygen-deprived environments, the corrosion resistance might be weakened. - Mechanical Stress: Excessive mechanical stress or deformation can disrupt the structure of the material and the integrity of the oxide layer, making it more susceptible to corrosion.

- Galvanic Coupling: When titanium mesh is in contact with other metals with different electrochemical potentials, galvanic corrosion can occur, affecting its corrosion resistance.

Company profile

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

Certification

Qixin is ISO 9001:2015 certified and own more than 10 patents. All its processes and procedures are documented and controlled in accordance with these standard. Qixin has strict product quality control procedure, from raw material to finished product, all the process is tested qualified to assure high quality product.

With technical engineers experienced for more than 18 years of constant research and production for titanium electrode and its application in various industries, Qixin can offer a very high level of technical support and products, which are among its most remarkable characteristics.

Why choose us?

1. Superior Material Quality & Durability

Corrosion Resistance: Titanium’s inherent resistance to acids, alkalis, and chloride-rich environments ensures long service life in demanding applications like cobalt electrowinning or wastewater treatment.

High Strength & Stability: Titanium maintains structural integrity under high currents and temperatures, reducing the risk of deformation or degradation.

Customized Coatings: We apply advanced oxide coatings (e.g., ruthenium, iridium, platinum group metals) tailored to your process, enhancing conductivity, catalytic activity, and longevity.

2. Technical Expertise & Custom Solutions

Tailored Design: We analyze your process parameters (current density, electrolyte composition, temperature) to design anodes that maximize efficiency.

R&D-Driven Innovation: Our team stays ahead of industry trends, integrating the latest coating technologies (e.g., mixed metal oxides, dimensionally stable anodes – DSAs) for performance gains.

Testing & Validation: Pre-production prototypes undergo rigorous testing to ensure compliance with your specifications.

3. Cost-Effectiveness & Sustainability

Lower Total Cost of Ownership (TCO):

Longevity reduces replacement frequency compared to traditional anodes (e.g., lead, graphite).

Energy-efficient designs cut electricity costs in large-scale operations.

Eco-Friendly: Titanium is recyclable, and our coatings minimize metal leaching, aligning with environmental regulations.

4. Reliable Service & Support

Global Supply Chain: Timely delivery through the streamlined manufacturing and logistics network.

Technical Support: Post-installation guidance, troubleshooting, and maintenance recommendations.

Compliance Assurance: Anodes meet international standards (e.g., ISO, SGS) and can be certified for specific industries (e.g., mining, water treatment).

Our Happy Clients