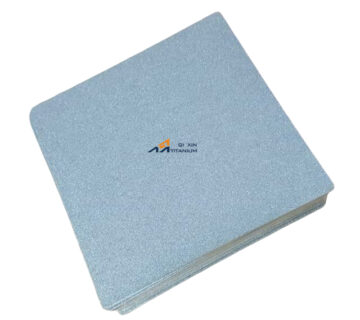

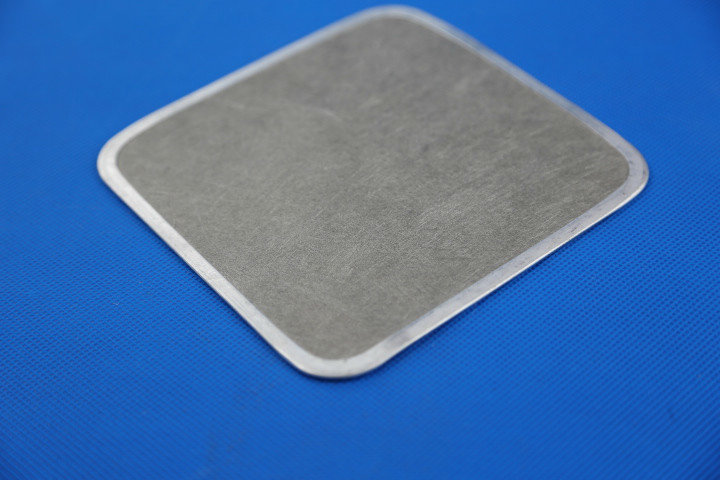

Titanium felt, also known as titanium fiber felt, is a porous and flexible material made from titanium fibers. It has a wide range of applications due to its excellent properties.

Manufacturing Process

Fiber production: Titanium fibers are produced by processes such as wire drawing, powder metallurgy, or chemical vapor deposition, and then cut to the desired length.

Felt formation: The titanium fibers are randomly oriented and formed into a mat or felt structure by methods such as air laying, wet laying, or carding.

Sintering: The felt mat is sintered in a high – temperature furnace under a controlled atmosphere, which bonds the fibers at their contact points to enhance the mechanical strength of the felt without affecting its porosity.

Post – processing: The sintered titanium felt may undergo additional processes such as rolling, cutting, or surface treatments to meet specific application requirements.

Advantages

High surface area: The porous structure provides a large surface area, which is beneficial for applications requiring high reactivity or surface interactions.

Corrosion resistance: Titanium’s inherent corrosion – resistance makes the felt suitable for harsh chemical environments.

Electrical conductivity: The conductive nature of titanium allows the felt to be used in electrical and electrochemical applications.

Mechanical strength: The sintered structure gives good mechanical stability and durability.

Flexibility: Despite its strength, titanium felt remains flexible and can conform to various shapes and surfaces.

Applications

Electrochemical applications: In fuel cells, it is used as a gas diffusion layer in proton exchange membrane fuel cells and solid oxide fuel cells due to its conductivity and corrosion resistance. In electrolyzers, it is used in water electrolysis systems for hydrogen production. It is also used as a current collector or electrode support in lithium – ion and other advanced batteries. In addition, it is used in the anode diffusion layer of PEM water electrolysis hydrogen production to improve electrolysis efficiency and reduce energy consumption.

Filtration and separation: It can be used as a support for catalysts in chemical reactors and reformers. It is also used in filtration systems for aggressive chemicals, high temperatures, and fine particulates, and can filter particles ranging from 1 to 300 microns.

Biomedical devices: Due to its biocompatibility, it is used in medical implants such as artificial joints and fracture internal fixators, as well as in scaffolds for tissue engineering and regenerative medicine.

Heat and mass transfer: It is used in heat exchangers where corrosion resistance and high thermal conductivity are required.

Who we are ?

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

Certification

Qixin is ISO 9001:2015 certified and own more than 10 patents. All its processes and procedures are documented and controlled in accordance with these standard. Qixin has strict product quality control procedure, from raw material to finished product, all the process is tested qualified to assure high quality product.

With technical engineers experienced for more than 18 years of constant research and production for titanium electrode and its application in various industries, Qixin can offer a very high level of technical support and products, which are among its most remarkable characteristics.

Why choose us?

1. Superior Material Quality & Durability

Corrosion Resistance: Titanium’s inherent resistance to acids, alkalis, and chloride-rich environments ensures long service life in demanding applications like cobalt electrowinning or wastewater treatment.

High Strength & Stability: Titanium maintains structural integrity under high currents and temperatures, reducing the risk of deformation or degradation.

Customized Coatings: We apply advanced oxide coatings (e.g., ruthenium, iridium, platinum group metals) tailored to your process, enhancing conductivity, catalytic activity, and longevity.

2. Technical Expertise & Custom Solutions

Tailored Design: We analyze your process parameters (current density, electrolyte composition, temperature) to design anodes that maximize efficiency.

R&D-Driven Innovation: Our team stays ahead of industry trends, integrating the latest coating technologies (e.g., mixed metal oxides, dimensionally stable anodes – DSAs) for performance gains.

Testing & Validation: Pre-production prototypes undergo rigorous testing to ensure compliance with your specifications.

3. Cost-Effectiveness & Sustainability

Lower Total Cost of Ownership (TCO):

Longevity reduces replacement frequency compared to traditional anodes (e.g., lead, graphite).

Energy-efficient designs cut electricity costs in large-scale operations.

Eco-Friendly: Titanium is recyclable, and our coatings minimize metal leaching, aligning with environmental regulations.

4. Reliable Service & Support

Global Supply Chain: Timely delivery through the streamlined manufacturing and logistics network.

Technical Support: Post-installation guidance, troubleshooting, and maintenance recommendations.

Compliance Assurance: Anodes meet international standards (e.g., ISO, SGS) and can be certified for specific industries (e.g., mining, water treatment).

FAQ

1. How to ensure the product quality?

All products make 100% inspection before shipment also we can provide the MTC Material Test Certification.

2. Can you print our Logo on the products?

Sure, and we welcome the customerized products.

3.What about the payment terms?.

T/T, L/C, Paypal, Western Union, Escrew and MoneyGram etc are all accepted.

4.What is the necessary information for an inquiry?

Product name, specification, material grade and quantity.

5.Can we get a free sample before cargo production?

Sure.