Maintaining clean and safe water in swimming pools is crucial for both the health of swimmers and the longevity of pool equipment. Chlorine remains a popular disinfectant for this purpose, and titanium electrodes have emerged as a highly efficient and reliable component in chlorine generation systems for swimming pools.

Titanium electrodes used in pool chlorinators typically consist of a titanium substrate, often made of high – purity titanium such as Grade 1 or Grade 2. Titanium’s natural resistance to corrosion makes it an ideal base material, especially in the chlorine – rich and humid environment of a swimming pool. This resistance is due to the formation of a thin, self – healing oxide layer (TiO₂) on the titanium surface when exposed to air or water.

The titanium substrate is then coated with mixed metal oxides (MMO), commonly ruthenium oxide (RuO₂) and iridium oxide (IrO₂). These coatings are applied through processes like thermal decomposition. The MMO coating plays a vital role in enhancing the electrode’s performance. Ruthenium oxide, for example, has excellent electrocatalytic properties for chlorine evolution reactions, while iridium oxide contributes to the stability and durability of the coating.

Types of Titanium Electrodes for Pool Chlorinators

Plate – type Titanium Electrodes

Plate – type titanium electrodes are a common design used in pool chlorinators. They are typically flat sheets of titanium with the MMO coating applied on one or both sides. These electrodes offer a large surface area for the electrochemical reactions to occur. In a pool chlorinator, the larger surface area allows for a higher rate of chlorine generation. Plate – type electrodes are often used in residential and small – to – medium – sized commercial pool chlorinators. Their flat design also makes them relatively easy to install and maintain within the chlorinator unit.

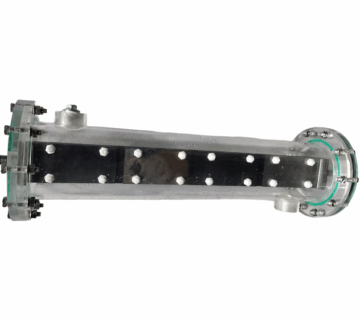

Tube – type Titanium Electrodes

Tube – type titanium electrodes are another option. These electrodes are in the form of hollow or solid tubes with the MMO coating. The tubular design can be beneficial in certain applications as it can provide a unique flow pattern for the pool water around the electrode. This can enhance the efficiency of the electrolysis process, especially in situations where the water flow needs to be carefully controlled. Tube – type electrodes are sometimes preferred in larger commercial pool systems or in pool chlorinators where space is limited, as their cylindrical shape can be more easily integrated into the overall system design.

Installation and Maintenance Considerations

Installation

Installing titanium electrodes in a pool chlorinator should be done following the manufacturer’s instructions carefully. The electrodes need to be properly positioned within the electrolytic cell of the chlorinator to ensure optimal water flow around them. In some cases, they may need to be connected to a power source with the correct voltage and current settings. For example, most residential pool chlorinators using titanium electrodes operate at a relatively low voltage (usually around 12 – 24 volts DC) to ensure safe and efficient operation. It is also important to ensure that the electrical connections are secure and protected from water to prevent electrical hazards.

Maintenance

Maintenance of titanium electrodes is relatively straightforward. Regularly checking the salt level in the pool water is essential, as the electrolysis process depends on an adequate supply of chloride ions. If the salt level is too low, the chlorine generation efficiency will decrease. Additionally, the electrodes may need to be cleaned periodically to remove any deposits that may accumulate on the surface. However, due to the smooth and non – reactive nature of the MMO – coated titanium, these deposits are usually minimal. In some cases, a simple rinse with clean water or a mild acid solution (as recommended by the manufacturer) may be sufficient to clean the electrodes. Monitoring the performance of the chlorinator, such as the chlorine output and the overall water quality, can also help in detecting any potential issues with the electrodes early on.

Key Advantages of Titanium Electrodes in Pool Chlorination

High Efficiency in Chlorine Generation

Titanium electrodes coated with MMOs have a significantly lower overpotential for chlorine evolution compared to other electrode materials. This means that less energy is required to drive the oxidation of chloride ions into chlorine gas. As a result, pool chlorinators equipped with titanium electrodes can generate chlorine more efficiently. For example, in a medium – sized residential pool (10,000 – 15,000 gallons), a titanium – electrode – based chlorinator can maintain the required chlorine levels (usually 1 – 3 ppm for residential pools) with lower power consumption compared to older – style chlorination systems.

Exceptional Durability

The combination of the corrosion – resistant titanium substrate and the stable MMO coating gives these electrodes a long service life. Titanium’s resistance to corrosion in the pool water environment, which contains chloride ions and is often subject to pH fluctuations, ensures that the electrode does not degrade easily. The MMO coating also remains intact over time, maintaining its electrocatalytic properties. In fact, under normal operating conditions, titanium electrodes can last for 5 – 10 years in a swimming pool chlorinator. This is in contrast to other electrode materials like graphite, which may need to be replaced every 1 – 2 years due to corrosion and degradation.

Consistent Chlorine Output

Titanium electrodes provide a consistent and stable output of chlorine. The electrocatalytic properties of the MMO coating ensure that the rate of chlorine generation remains relatively constant, as long as the salt concentration in the pool water is within the appropriate range (usually 2500 – 3500 ppm for salt – water pool chlorinators). This consistent chlorine output helps in maintaining a stable disinfectant level in the pool water. For commercial pools, such as those in hotels or water parks, where a large number of swimmers can affect the water quality rapidly, the consistent chlorine generation by titanium electrodes is crucial for ensuring water safety at all times.

Why choose us?

1. Superior Material Quality & Durability

Corrosion Resistance: Titanium’s inherent resistance to acids, alkalis, and chloride-rich environments ensures long service life in demanding applications like cobalt electrowinning or wastewater treatment.

High Strength & Stability: Titanium maintains structural integrity under high currents and temperatures, reducing the risk of deformation or degradation.

Customized Coatings: We apply advanced oxide coatings (e.g., ruthenium, iridium, platinum group metals) tailored to your process, enhancing conductivity, catalytic activity, and longevity.

2. Technical Expertise & Custom Solutions

Tailored Design: We analyze your process parameters (current density, electrolyte composition, temperature) to design anodes that maximize efficiency.

R&D-Driven Innovation: Our team stays ahead of industry trends, integrating the latest coating technologies (e.g., mixed metal oxides, dimensionally stable anodes – DSAs) for performance gains.

Testing & Validation: Pre-production prototypes undergo rigorous testing to ensure compliance with your specifications.

3. Cost-Effectiveness & Sustainability

Lower Total Cost of Ownership (TCO):

Longevity reduces replacement frequency compared to traditional anodes (e.g., lead, graphite).

Energy-efficient designs cut electricity costs in large-scale operations.

Eco-Friendly: Titanium is recyclable, and our coatings minimize metal leaching, aligning with environmental regulations.

4. Reliable Service & Support

Global Supply Chain: Timely delivery through the streamlined manufacturing and logistics network.

Technical Support: Post-installation guidance, troubleshooting, and maintenance recommendations.

Compliance Assurance: Anodes meet international standards (e.g., ISO, SGS) and can be certified for specific industries (e.g., mining, water treatment).

Company Profile

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

production

1. Substrate treatment: it needs to be treated by roughing, cleaning and removing oil, which can increase the compactness of catalytic.

2. Brushing coating:After substrate treatment, it will be proceeded brush coated. The main coated content is platinum group metal, which is a kind of mixed solution.Then, heat treatment will be going on after drying.The whole procedure need to be repeated many times. This method is better to form thin oxide catalytic that is lamellar adhere to substrate surface.

Quality assurance and after-sales service

1.We promise that our substrate is high quality,acceleratd life test.The coating solution is configured according to the certain proportion.

2.With the high technology and equipment,All of our tecnical personnel have abundant experience,and our workers are very skilled.During the production of the Titanium anode, each process must carry on the strict examination,Such as the detection of surface rougghness,The quality of coating solution,coating evenness and so on.

3.We have our own production,sales and after-service department.We are usually dedicated to provide customers with high quality and reasonable price product.Most importantly ,we can provide the efficient service.

4.Each procedure will be carefully detected in the technical staff to compelete.accomplish the order in time and delivery on time.

5.During our cooperation,if you have any problem ,you can contact us at anytime,we will do our umost to help you.