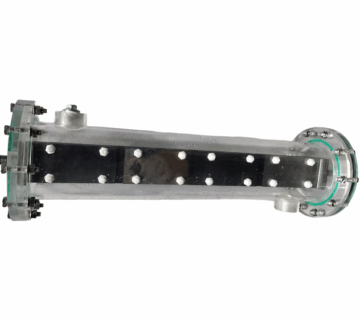

In the metal electrowinning process, metal ions in the electrolyte are reduced and deposited on the cathode, while at the anode, water is decomposed to release oxygen. The reaction at the titanium anode is usually: 2H2O → O2 + 4H+ + 4e-. Titanium anodes act as insoluble anodes, providing a stable current path, ensuring uniform current distribution, and facilitating the smooth progress of the electrolysis reaction.According to different coating materials, titanium anodes for metal electrowinning mainly include iridium – tantalum oxide – coated titanium anodes, ruthenium – iridium oxide – coated titanium anodes, etc. These coatings have excellent electrocatalytic activity and corrosion resistance, which can meet the requirements of different metal electrowinning processes.

Advantages of Titanium Anodes

High Corrosion Resistance: Titanium has good corrosion resistance in various acidic and alkaline electrolytes. For example, in the sulfuric acid – based electrolyte used in copper electrowinning, titanium anodes can maintain stable performance without being corroded, ensuring a long service life.

Low Energy Consumption: The metal oxide coating on the surface of titanium anodes has a low over – potential for oxygen evolution, which can reduce the working voltage of the anode and thus save electrical energy. Generally, the direct current consumption of titanium anodes can be reduced by 10% – 20% compared with other anodes.

High Current Efficiency: Titanium anodes can provide uniform current distribution, enabling efficient deposition of metals on the cathode. In copper electrowinning, using titanium anodes can increase current efficiency by 18%, and improve the purity of cathode copper from 99.95% to 99.997%.

Stable Performance: During the electrolysis process, the size of titanium anodes remains stable, and the distance between electrodes does not change, which can ensure the stability of electrolysis operation and the consistency of product quality.

Environment – Friendly: Compared with traditional lead – based anodes, titanium anodes do not produce heavy – metal pollution, which is beneficial to environmental protection. For example, using titanium anodes can reduce heavy – metal pollution emissions by 90%.

Titanium anodes are widely used in the electrowinning of non – ferrous metals such as copper, nickel, cobalt, and zinc. In copper electrowinning plants, titanium anodes can improve the quality of cathode copper and reduce production costs. In nickel and cobalt electrowinning, due to the strong corrosiveness of the electrolyte, titanium anodes with appropriate coatings are also the first – choice materials.

Why choose us?

1. Superior Material Quality & Durability

Corrosion Resistance: Titanium’s inherent resistance to acids, alkalis, and chloride-rich environments ensures long service life in demanding applications like cobalt electrowinning or wastewater treatment.

High Strength & Stability: Titanium maintains structural integrity under high currents and temperatures, reducing the risk of deformation or degradation.

Customized Coatings: We apply advanced oxide coatings (e.g., ruthenium, iridium, platinum group metals) tailored to your process, enhancing conductivity, catalytic activity, and longevity.

2. Technical Expertise & Custom Solutions

Tailored Design: We analyze your process parameters (current density, electrolyte composition, temperature) to design anodes that maximize efficiency.

R&D-Driven Innovation: Our team stays ahead of industry trends, integrating the latest coating technologies (e.g., mixed metal oxides, dimensionally stable anodes – DSAs) for performance gains.

Testing & Validation: Pre-production prototypes undergo rigorous testing to ensure compliance with your specifications.

3. Cost-Effectiveness & Sustainability

Lower Total Cost of Ownership (TCO):

Longevity reduces replacement frequency compared to traditional anodes (e.g., lead, graphite).

Energy-efficient designs cut electricity costs in large-scale operations.

Eco-Friendly: Titanium is recyclable, and our coatings minimize metal leaching, aligning with environmental regulations.

4. Reliable Service & Support

Global Supply Chain: Timely delivery through the streamlined manufacturing and logistics network.

Technical Support: Post-installation guidance, troubleshooting, and maintenance recommendations.

Compliance Assurance: Anodes meet international standards (e.g., ISO, SGS) and can be certified for specific industries (e.g., mining, water treatment).

Company Profile

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

production

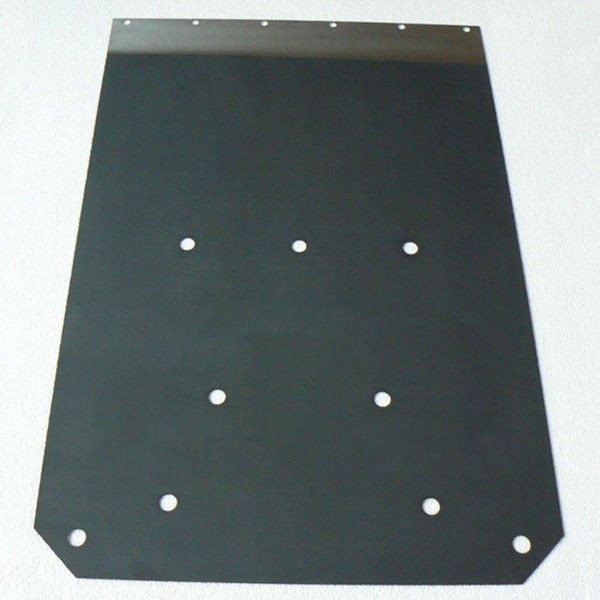

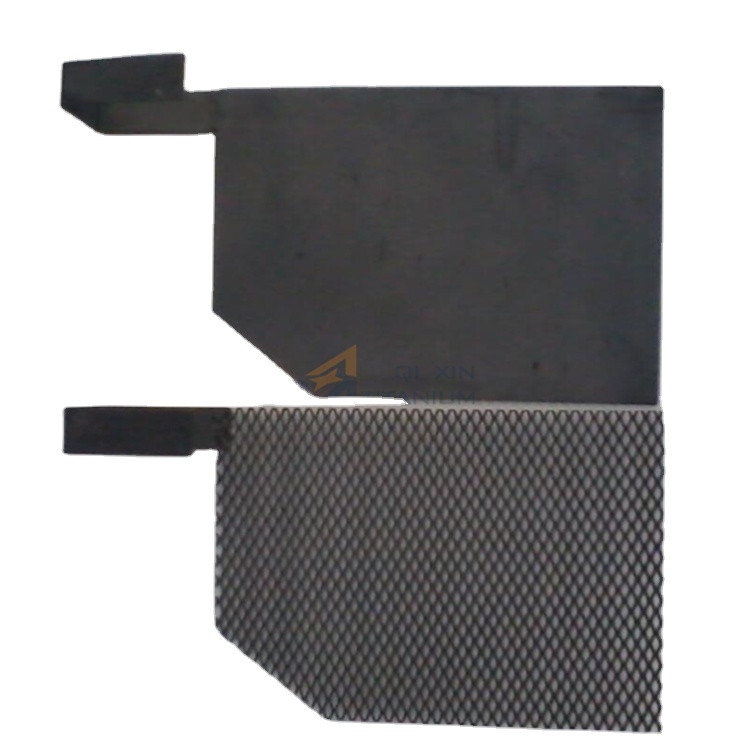

1. Substrate treatment: it needs to be treated by roughing, cleaning and removing oil, which can increase the compactness of catalytic.

2. Brushing coating:After substrate treatment, it will be proceeded brush coated. The main coated content is platinum group metal, which is a kind of mixed solution.Then, heat treatment will be going on after drying.The whole procedure need to be repeated many times. This method is better to form thin oxide catalytic that is lamellar adhere to substrate surface.

Quality assurance and after-sales service

1. We promise that our substrate is high quality,acceleratd life test.The coating solution is configured according to the certain proportion.

2.With the high technology and equipment,All of our tecnical personnel have abundant experience,and our workers are very skilled.During the production of the Titanium anode, each process must carry on the strict examination,Such as the detection of surface rougghness,The quality of coating solution,coating evenness and so on.

3.We have our own production,sales and after-service department.We are usually dedicated to provide customers with high quality and reasonable price product.Most importantly ,we can provide the efficient service.

4.Each procedure will be carefully detected in the technical staff to compelete.accomplish the order in time and delivery on time.

5.During our cooperation,if you have any problem ,you can contact us at anytime,we will do our umost to help you.