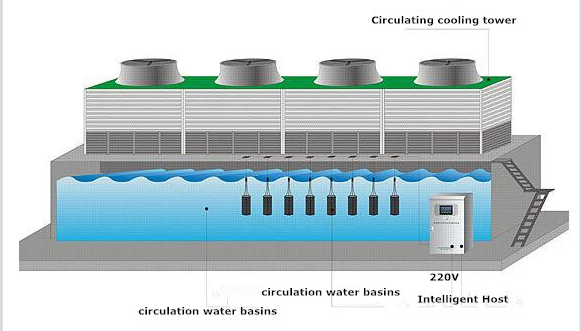

Cooling towers are workhorses in industrial facilities, but mineral scale—calcium carbonate, magnesium silicate, and rust deposits—plagues their efficiency. Over time, scale clogs pipes, reduces heat transfer, and forces systems to work harder, hiking energy costs. Titanium anode baskets offer a proactive, chemical-free way to tackle this problem, using electrolysis to prevent scale buildup and extend equipment life.

How Titanium Anode Baskets Work for Descaling

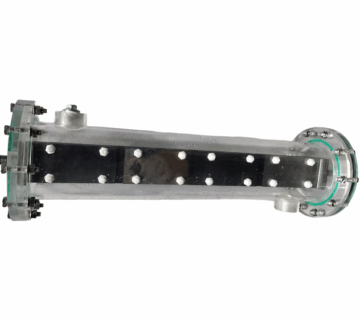

A titanium anode basket for cooling towers is a submerged device typically made of:

A porous titanium basket (mesh or perforated design) holding titanium anodes (often ruthenium iridium coating).

Titanium’s corrosion resistance ensures the basket itself withstands the tower’s harsh environment—high humidity, fluctuating pH (6–8), and mineral-rich water.

When connected to a low-voltage power supply, the basket acts as an anode in an electrolytic cell. The process:

Electrolysis: Electric current splits water molecules, generating hydroxyl ions (OH⁻) that raise local pH near metal surfaces.

Scale Prevention: The slight pH shift (to 8.0–8.5) converts dissolved calcium and magnesium ions into loose, non-adherent precipitates (e.g., aragonite) instead of hard, sticky scale. These particles are flushed out during regular tower blowdown.

Cathodic Protection: The basket’s current also creates a protective layer on metal pipes, reducing rust and corrosion that exacerbate scale buildup.

Key Benefits for Cooling Towers

1. Reduces Chemical Dependence

Traditional descaling relies on acids or anti-scaling chemicals, which corrode equipment over time and require careful handling.

No risk of over-dosing, which can damage tower liners or harm aquatic life in discharge water.

2. Low Maintenance, Long Lifespan

Basket Durability: Titanium resists pitting and corrosion in tower water, lasting 5–8 years—far longer than stainless steel baskets (2–3 years).

3. Energy Efficiency

Scale buildup on heat exchanger coils can reduce cooling efficiency by 30%. By preventing scale, anode baskets keep systems running at peak performance.

Applications

Industrial Cooling Towers: Handles large systems in power plants, refineries, and manufacturing facilities (10,000+ gallon capacity).

Commercial Towers: Fits smaller setups in hotels, hospitals, and office complexes, where chemical storage space is limited.

Hard Water Regions: Particularly effective in areas with high calcium/magnesium levels, where scale forms rapidly.

Company Profile

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

production

1. Substrate treatment: it needs to be treated by roughing, cleaning and removing oil, which can increase the compactness of catalytic.

2. Brushing coating:After substrate treatment, it will be proceeded brush coated. The main coated content is platinum group metal, which is a kind of mixed solution.Then, heat treatment will be going on after drying.The whole procedure need to be repeated many times. This method is better to form thin oxide catalytic that is lamellar adhere to substrate surface.

Why choose us?

1. Superior Material Quality & Durability

Corrosion Resistance: Titanium’s inherent resistance to acids, alkalis, and chloride-rich environments ensures long service life in demanding applications like cobalt electrowinning or wastewater treatment.

High Strength & Stability: Titanium maintains structural integrity under high currents and temperatures, reducing the risk of deformation or degradation.

Customized Coatings: We apply advanced oxide coatings (e.g., ruthenium, iridium, platinum group metals) tailored to your process, enhancing conductivity, catalytic activity, and longevity.

2. Technical Expertise & Custom Solutions

Tailored Design: We analyze your process parameters (current density, electrolyte composition, temperature) to design anodes that maximize efficiency.

R&D-Driven Innovation: Our team stays ahead of industry trends, integrating the latest coating technologies (e.g., mixed metal oxides, dimensionally stable anodes – DSAs) for performance gains.

Testing & Validation: Pre-production prototypes undergo rigorous testing to ensure compliance with your specifications.

3. Cost-Effectiveness & Sustainability

Lower Total Cost of Ownership (TCO):

Longevity reduces replacement frequency compared to traditional anodes (e.g., lead, graphite).

Energy-efficient designs cut electricity costs in large-scale operations.

Eco-Friendly: Titanium is recyclable, and our coatings minimize metal leaching, aligning with environmental regulations.

4. Reliable Service & Support

Global Supply Chain: Timely delivery through the streamlined manufacturing and logistics network.

Technical Support: Post-installation guidance, troubleshooting, and maintenance recommendations.

Compliance Assurance: Anodes meet international standards (e.g., ISO, SGS) and can be certified for specific industries (e.g., mining, water treatment).

FAQ

1. How to ensure the product quality?

All products make 100% inspection before shipment also we can provide the MTC Material Test Certification.

2. Can you print our Logo on the products?

Sure, and we welcome the customerized products.

3.What about the payment terms?.

T/T, L/C, Paypal, Western Union, Escrew and MoneyGram etc are all accepted.

4.What is the necessary information for an inquiry?

Product name, specification, material grade and quantity.

5.Can we get a free sample before cargo production?

Sure.