Maintaining crystal-clear, safe swimming pool water is a constant challenge—balancing sanitation, preventing algae growth, and avoiding harsh chemical overuse. Titanium anode assemblies have emerged as a game-changer in pool maintenance, offering a durable, efficient alternative to traditional chlorine tablets or saltwater generators. Here’s how they work and why they’re becoming a staple in both residential and commercial pools.

How Titanium Anode Assemblies Work in Pools

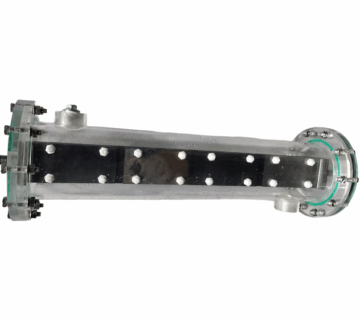

A typical titanium anode assembly for pools consists of several key components:

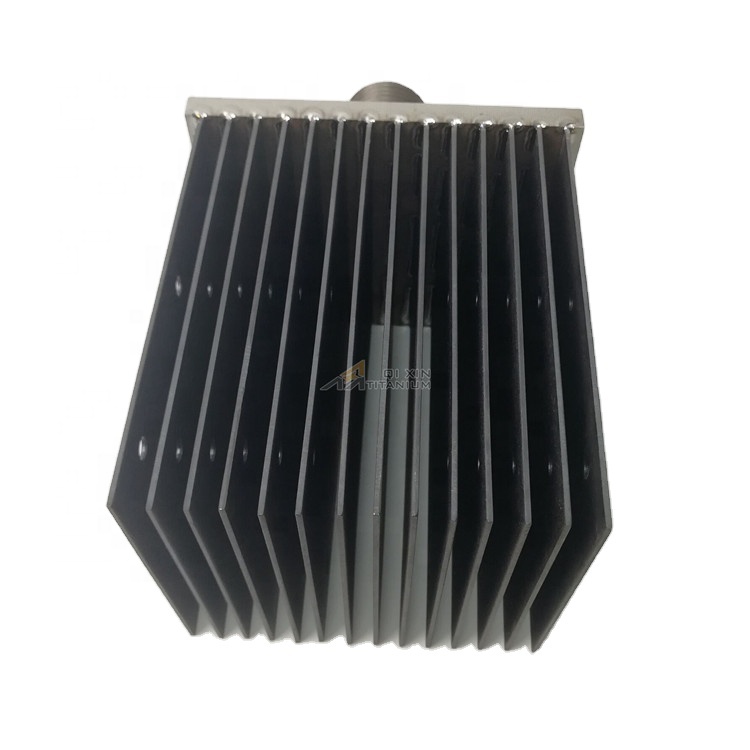

Titanium anode rods (coated with mixed metal oxides like ruthenium or iridium oxide) that act as catalysts.

A power supply that delivers a low-voltage current to the anodes.

A mounting frame (often PVC or stainless steel) to position the anodes in the pool’s circulation system, usually near the filter or return lines.

When energized, the anodes trigger electrolysis in the pool water. In saltwater pools (with 2,500–3,500 ppm salinity), this process splits chloride ions to generate chlorine gas, which dissolves into hypochlorous acid—a natural sanitizer that kills bacteria and algae. In freshwater pools, the system can still work with minimal salt added, reducing reliance on store-bought chlorine.

Key Features for Swimming Pools

1. Consistent Sanitization Without Chemical Spikes

Traditional chlorine dosing often leads to fluctuating levels—too little, and algae blooms; too much, and eyes sting, swimsuits fade. Titanium anode assemblies produce a steady stream of chlorine, maintaining levels between 1–3 ppm (ideal for safe swimming).

2. Durability in Chlorine-Rich Environments

Pool water is harsh: high chlorine, pH swings, and constant exposure to sunlight. Titanium’s natural resistance to corrosion, paired with a mixed metal oxide coating, makes these assemblies last 5–8 years—far longer than stainless steel anodes, which often degrade within 2 years.

3. Reduced Chemical Handling and Costs

No more hauling heavy chlorine buckets or storing volatile tablets. Titanium anode systems use the pool’s existing salt (or a small initial dose) to generate sanitizer, cutting chemical costs by 30–50% annually.

4. Gentle on Skin and Equipment

Over-chlorinated water irritates skin and eyes, and harsh chemicals can corrode pool liners, ladders, and pumps. Titanium anode systems produce “softer” chlorine (hypochlorous acid) that’s less irritating, while their steady output avoids the pH crashes that damage equipment.

Practical Applications

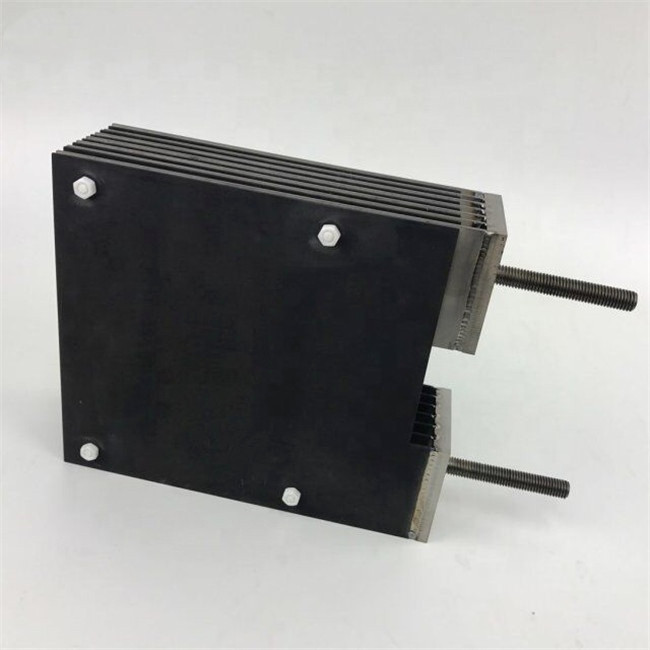

Residential Pools: Compact assemblies (3–5 anodes) fit easily into standard filtration systems, ideal for 10,000–30,000 gallon pools. They integrate with smart pool controllers, adjusting output based on water flow and temperature.

Commercial Pools: Larger setups (10+ anodes) handle public pools, water parks, and hotel facilities.

Saltwater Pools: Enhance existing salt systems by replacing worn stainless steel anodes with titanium ones, extending the system’s life and reducing salt consumption.

Company Profile

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

production

1. Substrate treatment: it needs to be treated by roughing, cleaning and removing oil, which can increase the compactness of catalytic.

2. Brushing coating:After substrate treatment, it will be proceeded brush coated. The main coated content is platinum group metal, which is a kind of mixed solution.Then, heat treatment will be going on after drying.The whole procedure need to be repeated many times. This method is better to form thin oxide catalytic that is lamellar adhere to substrate surface.

Why choose us?

1. Superior Material Quality & Durability

Corrosion Resistance: Titanium’s inherent resistance to acids, alkalis, and chloride-rich environments ensures long service life in demanding applications like cobalt electrowinning or wastewater treatment.

High Strength & Stability: Titanium maintains structural integrity under high currents and temperatures, reducing the risk of deformation or degradation.

Customized Coatings: We apply advanced oxide coatings (e.g., ruthenium, iridium, platinum group metals) tailored to your process, enhancing conductivity, catalytic activity, and longevity.

2. Technical Expertise & Custom Solutions

Tailored Design: We analyze your process parameters (current density, electrolyte composition, temperature) to design anodes that maximize efficiency.

R&D-Driven Innovation: Our team stays ahead of industry trends, integrating the latest coating technologies (e.g., mixed metal oxides, dimensionally stable anodes – DSAs) for performance gains.

Testing & Validation: Pre-production prototypes undergo rigorous testing to ensure compliance with your specifications.

3. Cost-Effectiveness & Sustainability

Lower Total Cost of Ownership (TCO):

Longevity reduces replacement frequency compared to traditional anodes (e.g., lead, graphite).

Energy-efficient designs cut electricity costs in large-scale operations.

Eco-Friendly: Titanium is recyclable, and our coatings minimize metal leaching, aligning with environmental regulations.

4. Reliable Service & Support

Global Supply Chain: Timely delivery through the streamlined manufacturing and logistics network.

Technical Support: Post-installation guidance, troubleshooting, and maintenance recommendations.

Compliance Assurance: Anodes meet international standards (e.g., ISO, SGS) and can be certified for specific industries (e.g., mining, water treatment).

FAQ

1. How to ensure the product quality?

All products make 100% inspection before shipment also we can provide the MTC Material Test Certification.

2. Can you print our Logo on the products?

Sure, and we welcome the customerized products.

3.What about the payment terms?.

T/T, L/C, Paypal, Western Union, Escrew and MoneyGram etc are all accepted.

4.What is the necessary information for an inquiry?

Product name, specification, material grade and quantity.

5.Can we get a free sample before cargo production?

Sure.