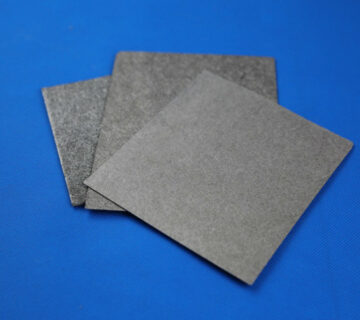

Stainless Steel Metal Porous Sintered Filter refers to a filter made of stainless steel powder through a sintering process, featuring a porous structure.

Basic Information

Materials: Common materials include stainless steel 304, 304L, 316, and 316L. Among them, 316L stainless steel is widely used due to its excellent corrosion resistance.

Pore Size and Porosity: The pore size range is usually 0.1μm – 120μm, and the porosity is generally 30% – 45%. Different pore sizes and porosities can be selected according to specific application requirements.

Working Pressure and Temperature: It can usually withstand a working pressure of up to 3MPa or more, and some products can work stably under high – pressure fluid conditions of 40MPa. The operating temperature can reach 600℃.

Production Process

Powder Preparation: Select stainless steel powder with appropriate particle size and composition.

Molding: The powder is formed by methods such as isostatic compaction to obtain a pre – formed body with a certain shape and density.

Sintering: The pre – formed body is sintered in a vacuum or protective atmosphere at a high temperature close to but below the melting point of stainless steel. During the sintering process, the stainless steel particles are bonded to each other to form a porous structure.

Advantages

High Filtration Accuracy: The pore size is accurate and uniform, which can effectively intercept particles of different sizes and achieve high – efficiency filtration.

Good Permeability: Although it has a filtering function, it also has good air permeability and liquid permeability, allowing the fluid to pass through smoothly.

Strong Structural Stability: The particles are closely combined, without migration, and have high fatigue strength and impact stress resistance. It can maintain structural stability under harsh environments and high – pressure conditions.

Corrosion Resistance: Stainless steel materials endow the filter with good corrosion – resistance and oxidation – resistance, and it can be used in various corrosive media such as nitric acid, sulfuric acid, and acetic acid.

Reusability: It can be cleaned by methods such as back – flushing and ultrasonic cleaning, and has strong regeneration ability, which can be reused many times, reducing the cost of use.

Applications

Filtration and Separation: It is widely used in the filtration of liquids and gases in the chemical, petroleum, pharmaceutical, food, and beverage industries, such as the removal of impurities in chemical raw materials, the clarification of food and beverage products, and the filtration of precious metal catalysts in the petrochemical industry.

Fluid Distribution: Due to its uniform pore structure, it can be used for fluid distribution and homogenization treatment, such as in the gas – liquid distribution system in the reactor.

Noise Reduction: Its porous structure has a certain noise – reduction effect and can be used in some occasions where noise needs to be reduced.

Who we are?

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

Production

Brush coating.

Specific operation as follows:

Firstly,making the coating solution according to the type and the area of the platinum electrode; secondly ,put the solution on the surface evenly, then put them into the drying furance for drying; thirdly,we need to oxidate in the high temperature oxidation furance;Lastly, dry it to room temperature. Then,repeat these steps until you run out the configuration solution.

Certification

Qixin is ISO 9001:2015 certified and own more than 10 patents. All its processes and procedures are documented and controlled in accordance with these standard. Qixin has strict product quality control procedure, from raw material to finished product, all the process is tested qualified to assure high quality product.

With technical engineers experienced for more than 18 years of constant research and production for titanium electrode and its application in various industries, Qixin can offer a very high level of technical support and products, which are among its most remarkable characteristics.

FAQ

1. How to ensure the product quality?

All products make 100% inspection before shipment also we can provide the MTC Material Test Certification.

2. Can you print our Logo on the products?

Sure, and we welcome the customerized products.

3.What about the payment terms?.

T/T, L/C, Paypal, Western Union, Escrew and MoneyGram etc are all accepted.

4.What is the necessary information for an inquiry?

Product name, specification, material grade and quantity.

5.Can we get a free sample before cargo production?

Sure.