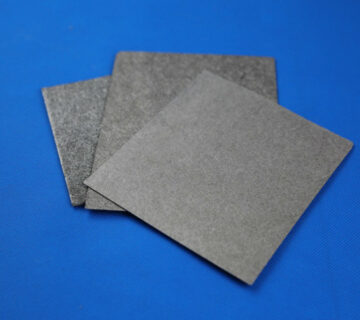

The sintered stainless steel micro air stone ozone bubble diffuser is a core component in ozone-based water treatment systems, specifically designed to maximize the contact efficiency between ozone (O₃) and water. By generating ultra-fine, uniform bubbles, it enhances ozone dissolution—critical for achieving effective disinfection, oxidation of organic contaminants, and algae control in applications like swimming pools, aquaculture, and wastewater treatment.The core part is made of sintered 316L stainless steel (a corrosion-resistant alloy with high chromium and nickel content). Unlike traditional ceramic or plastic diffusers, 316L stainless steel resists oxidation by ozone and chemical erosion from treated water (e.g., chlorine, acids), avoiding material degradation or particle shedding that could contaminate water.

Ozone is a powerful but unstable oxidant; its effectiveness depends on how well it dissolves in water (rather than escaping as undissolved gas). This diffuser solves the “low dissolution” problem of traditional diffusers through the following steps:

Gas Input: Ozone gas (generated by an ozone generator) is delivered to the diffuser via a dedicated pipeline, entering the sintered stainless steel diffusion body.

Micro-Bubble Generation: As ozone flows through the micro-pores (5–50 μm), the gas is split into ultra-fine bubbles (diameter <100 μm, often 20–50 μm). Compared to large bubbles (e.g., 1–5 mm from standard air stones), micro-bubbles have a massively increased surface area-to-volume ratio (e.g., a 50 μm bubble has ~100x more surface area than a 500 μm bubble of the same volume).

Enhanced Mass Transfer: The tiny bubbles rise slowly in water (due to their small size and low buoyancy), extending the contact time between ozone and water. This allows more ozone to dissolve into the water (dissolution efficiency can reach 85–95%, vs. 40–60% for traditional diffusers) rather than escaping into the air as waste.

Oxidation & Disinfection: Dissolved ozone acts on water contaminants—destroying bacteria, viruses, and algae by breaking down their cell walls and genetic material; oxidizing organic matter (e.g., swimmers’ sweat, sunscreen) and residual chlorine byproducts (e.g., chloramines); and eliminating odors (e.g., the “chlorine smell” in pools).

Advantages

Exceptional Corrosion Resistance:316L stainless steel resists ozone oxidation and chemical attack (e.g., acidic water, chlorine). Service life is 5–10 years, vs. 1–2 years for ceramic/plastic diffusers (which often crack or degrade).

High Ozone Dissolution Efficiency:Ultra-fine bubbles (20–50 μm) and slow rise speed boost dissolution to 85–95%, reducing ozone generator energy consumption (less gas is wasted) and improving water treatment effects.

Uniform Bubble Distribution:Sintered micro-pores ensure consistent bubble size across the diffuser surface, avoiding “dead zones” (areas with no ozone) in the water—critical for large pools or tanks.

Easy Cleaning & Maintenance:Stainless steel’s smooth surface prevents organic fouling (e.g., algae, slime) from adhering. If clogging occurs, it can be cleaned with dilute acid (e.g., 5% citric acid) or high-pressure water, without damaging the pore structure.

Wide Temperature & Pressure Adaptability:Withstands water temperatures of -10°C to 80°C and gas pressures of 0.1–0.5 MPa, suitable for both cold (e.g., outdoor pools in winter) and warm (e.g., spa pools) water environments.

Application Scenarios

Its durability and high efficiency make it ideal for ozone water treatment in scenarios requiring strict water quality standards:

(1) Swimming Pools & Spas

Role: Works with ozone generators to replace or supplement chlorine disinfection. It reduces chlorine usage by 50–70%, minimizing skin/eye irritation and “chlorine smell”; oxidizes chloramines (the main cause of pool odors and respiratory discomfort); and controls algae growth (keeping pool walls clean).

Installation: Usually placed at the bottom of the pool (evenly spaced every 2–4 meters) or in the circulation system’s mixing tank, ensuring ozone mixes fully with returning pool water.

(2) Aquaculture (Fish Farms, Aquariums)

Role: Disinfects fish tank/pond water to kill pathogenic bacteria (e.g., Aeromonas) and parasites, reducing fish mortality; oxidizes ammonia (a toxic waste from fish excrement) into harmless nitrate; and increases dissolved oxygen (micro-bubbles release oxygen as ozone decomposes).

Advantage: Stainless steel is non-toxic and does not leach harmful substances, making it safe for sensitive aquatic life (e.g., ornamental fish, shrimp).

(3) Wastewater Treatment (Industrial/Residential)

Role: Used in secondary or advanced wastewater treatment to oxidize refractory organic pollutants (e.g., dyes, pharmaceuticals) that biological treatment cannot break down; disinfects wastewater before discharge to meet environmental standards.

Suitability: Resists the high chemical load of industrial wastewater (e.g., printing and dyeing wastewater, food processing wastewater) better than ceramic diffusers.

(4) Drinking Water Purification

Role: In small-scale drinking water systems (e.g., rural communities, campgrounds), it disinfects raw water to kill E. coli, Giardia, and other pathogens; removes odors (e.g., earthy smells from algae) and improves water taste.

Company Profile

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

production

1. Substrate treatment: it needs to be treated by roughing, cleaning and removing oil, which can increase the compactness of catalytic.

2. Brushing coating:After substrate treatment, it will be proceeded brush coated. The main coated content is platinum group metal, which is a kind of mixed solution.Then, heat treatment will be going on after drying.The whole procedure need to be repeated many times. This method is better to form thin oxide catalytic that is lamellar adhere to substrate surface.

Why choose us?

1. Superior Material Quality & Durability

Corrosion Resistance: Titanium’s inherent resistance to acids, alkalis, and chloride-rich environments ensures long service life in demanding applications like cobalt electrowinning or wastewater treatment.

High Strength & Stability: Titanium maintains structural integrity under high currents and temperatures, reducing the risk of deformation or degradation.

Customized Coatings: We apply advanced oxide coatings (e.g., ruthenium, iridium, platinum group metals) tailored to your process, enhancing conductivity, catalytic activity, and longevity.

2. Technical Expertise & Custom Solutions

Tailored Design: We analyze your process parameters (current density, electrolyte composition, temperature) to design anodes that maximize efficiency.

R&D-Driven Innovation: Our team stays ahead of industry trends, integrating the latest coating technologies (e.g., mixed metal oxides, dimensionally stable anodes – DSAs) for performance gains.

Testing & Validation: Pre-production prototypes undergo rigorous testing to ensure compliance with your specifications.

3. Cost-Effectiveness & Sustainability

Lower Total Cost of Ownership (TCO):

Longevity reduces replacement frequency compared to traditional anodes (e.g., lead, graphite).

Energy-efficient designs cut electricity costs in large-scale operations.

Eco-Friendly: Titanium is recyclable, and our coatings minimize metal leaching, aligning with environmental regulations.

4. Reliable Service & Support

Global Supply Chain: Timely delivery through the streamlined manufacturing and logistics network.

Technical Support: Post-installation guidance, troubleshooting, and maintenance recommendations.

Compliance Assurance: Anodes meet international standards (e.g., ISO, SGS) and can be certified for specific industries (e.g., mining, water treatment).

FAQ

1. How to ensure the product quality?

All products make 100% inspection before shipment also we can provide the MTC Material Test Certification.

2. Can you print our Logo on the products?

Sure, and we welcome the customerized products.

3.What about the payment terms?.

T/T, L/C, Paypal, Western Union, Escrew and MoneyGram etc are all accepted.

4.What is the necessary information for an inquiry?

Product name, specification, material grade and quantity.

5.Can we get a free sample before cargo production?

Sure.