The ruthenium-iridium coated titanium anode (Ti/RuO₂-IrO₂) is a pivotal component in refuse leachate treatment, leveraging its unique electrochemical properties to address the complex challenges posed by this hazardous wastewater.

Mechanisms of Refuse Leachate Treatment

Direct Oxidation: Active sites on the anode surface adsorb organic compounds (e.g., humic acids, refractory hydrocarbons), decomposing them into CO₂ and H₂O through electron transfer.

Indirect Oxidation: In high-Cl⁻ environments, the anode catalyzes the generation of strong oxidants (e.g., ClO⁻, ·OH), which synergistically degrade persistent pollutants (e.g., heavy metal complexes).

Biodegradability Enhancement: By breaking molecular chains and rings, the anode improves the BOD/COD (B/C) ratio from 0.15 to 0.38 (e.g., in electrocoagulation combined with Ti/RuO₂-IrO₂), facilitating subsequent biological treatment.

Advantage

Electrocatalytic Activity: RuO₂ lowers the overpotential for chlorine evolution, while IrO₂ enhances oxygen evolution stability. This synergy accelerates the oxidation of organic pollutants (e.g., COD, ammonia nitrogen) and the removal of heavy metals, making it ideal for high-salinity (Cl⁻), high-organic-load, and toxic refuse leachate.

Corrosion Resistance: The titanium substrate resists chemical attack, and the oxide coating remains stable under acidic conditions (pH < 7) and high chloride concentrations (e.g., 6.5 g/L Cl⁻), with a service life of 1–3 years—significantly longer than traditional graphite or iron anodes.

Cost-Effectiveness: Compared to boron-doped diamond (BDD) anodes, it offers a more economical solution for large-scale engineering applications.

Application

1.Advanced Treatment of Biologically Refractory Wastewater

Persistent organic compounds (e.g., polycyclic aromatic hydrocarbons, pharmaceutical residues), high ammonia nitrogen (NH₃-N), and heavy metals (Cr⁶⁺, Cd²⁺) that resist conventional biological degradation.

2.Membrane Concentrate Treatment

Challenge: High salinity (TDS > 10,000 mg/L) and low biodegradability (B/C < 0.2) in reverse osmosis (RO) concentrate.

Solution: Electrochemical oxidation with Ti/RuO₂-IrO₂ anodes combined with nanofiltration, achieving 60–70% COD removal and reducing membrane fouling by 40%.

3.Heavy Metal and Color Removal

Mechanism: Anodic oxidation converts heavy metals to insoluble oxides/hydroxides (e.g., Fe²⁺→Fe³⁺), while electrophoretic migration of chromophoric groups (e.g., azo dyes) enhances color removal (efficiency >90%).

Company Profile

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

production

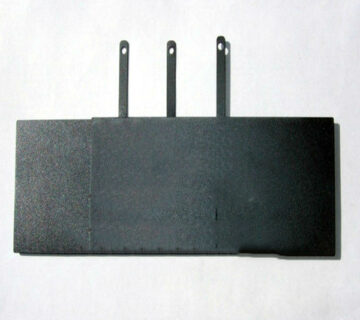

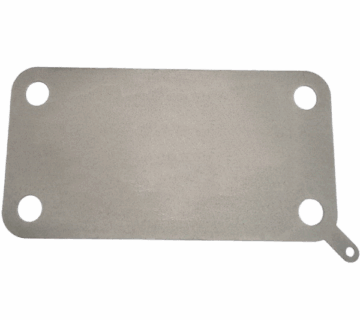

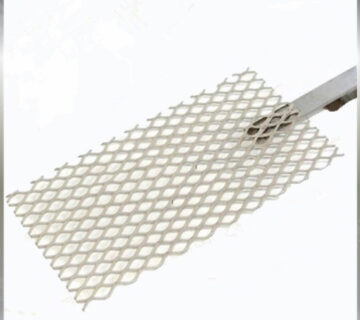

1. Substrate treatment: it needs to be treated by roughing, cleaning and removing oil, which can increase the compactness of catalytic.

2. Brushing coating:After substrate treatment, it will be proceeded brush coated. The main coated content is platinum group metal, which is a kind of mixed solution.Then, heat treatment will be going on after drying.The whole procedure need to be repeated many times. This method is better to form thin oxide catalytic that is lamellar adhere to substrate surface.

Why choose us?

1. Superior Material Quality & Durability

Corrosion Resistance: Titanium’s inherent resistance to acids, alkalis, and chloride-rich environments ensures long service life in demanding applications like cobalt electrowinning or wastewater treatment.

High Strength & Stability: Titanium maintains structural integrity under high currents and temperatures, reducing the risk of deformation or degradation.

Customized Coatings: We apply advanced oxide coatings (e.g., ruthenium, iridium, platinum group metals) tailored to your process, enhancing conductivity, catalytic activity, and longevity.

2. Technical Expertise & Custom Solutions

Tailored Design: We analyze your process parameters (current density, electrolyte composition, temperature) to design anodes that maximize efficiency.

R&D-Driven Innovation: Our team stays ahead of industry trends, integrating the latest coating technologies (e.g., mixed metal oxides, dimensionally stable anodes – DSAs) for performance gains.

Testing & Validation: Pre-production prototypes undergo rigorous testing to ensure compliance with your specifications.

3. Cost-Effectiveness & Sustainability

Lower Total Cost of Ownership (TCO):

Longevity reduces replacement frequency compared to traditional anodes (e.g., lead, graphite).

Energy-efficient designs cut electricity costs in large-scale operations.

Eco-Friendly: Titanium is recyclable, and our coatings minimize metal leaching, aligning with environmental regulations.

4. Reliable Service & Support

Global Supply Chain: Timely delivery through the streamlined manufacturing and logistics network.

Technical Support: Post-installation guidance, troubleshooting, and maintenance recommendations.

Compliance Assurance: Anodes meet international standards (e.g., ISO, SGS) and can be certified for specific industries (e.g., mining, water treatment).

FAQ

1. How to ensure the product quality?

All products make 100% inspection before shipment also we can provide the MTC Material Test Certification.

2. Can you print our Logo on the products?

Sure, and we welcome the customerized products.

3.What about the payment terms?.

T/T, L/C, Paypal, Western Union, Escrew and MoneyGram etc are all accepted.

4.What is the necessary information for an inquiry?

Product name, specification, material grade and quantity.

5.Can we get a free sample before cargo production?

Sure.