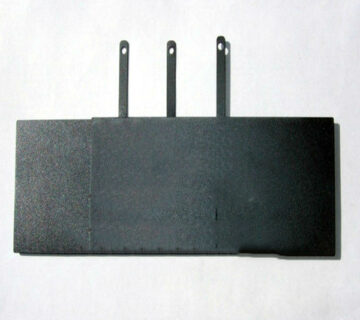

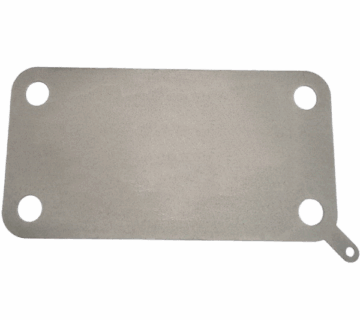

Hard chrome plating is an electrochemical process that deposits a thick, hard layer of chromium onto a metal substrate to enhance its wear resistance, hardness, corrosion resistance, and surface durability. It is widely used in various industrial applications to improve the performance and service life of components.A platinum titanium anode is a specialized electrode material commonly used in the hard chrome plating process.

Comparison with Other Anode Materials

| Anode Material | Corrosion Resistance | Electrical Conductivity | Environmental Impact | Service Life | Cost |

|---|---|---|---|---|---|

| Platinum-Titanium | Excellent | High | Low (non-toxic) | Long | High |

| Lead | Good (in chromic acid) | Moderate | High (lead pollution) | Medium | Low |

| Stainless Steel | Poor (prone to corrosion) | Moderate | Low | Short | Medium |

Advantages in Hard Chrome Plating

Superior Corrosion Resistance

The platinum coating effectively resists the corrosion of chromic acid (H₂CrO₄) and other strong oxidizing agents in the plating solution, ensuring a long service life of the anode.

Unlike lead anodes (traditionally used in chrome plating), platinum-titanium anodes do not dissolve in the electrolyte, avoiding contamination of the plating solution and improving the purity of the chrome coating.

Stable Electrical Performance

Platinum has excellent electrical conductivity, ensuring uniform current distribution during the plating process and promoting the formation of a dense and uniform hard chrome layer.

It maintains stable electrochemical properties over a wide range of current densities, which is crucial for controlling the plating rate and coating quality.

Environmental Friendliness

Lead anodes can release lead ions into the solution, posing environmental and health risks. Platinum-titanium anodes are free of toxic metals, reducing the generation of hazardous waste and facilitating compliance with environmental protection regulations.

Long Service Life

With proper maintenance, a platinum-titanium anode can be used for an extended period, reducing the frequency of anode replacement and lowering production costs.

Application

Industrial Manufacturing: Widely used in the plating of mechanical parts such as pistons, cylinder liners, gears, and shafts to enhance their wear resistance, hardness, and corrosion resistance.

Aerospace and Automotive Industries: For plating components that require high-performance surfaces, such as aerospace fasteners and automotive engine parts.

Mold and Tool Manufacturing: To improve the service life of molds and tools by plating hard chrome on their surfaces.

Who we are?

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

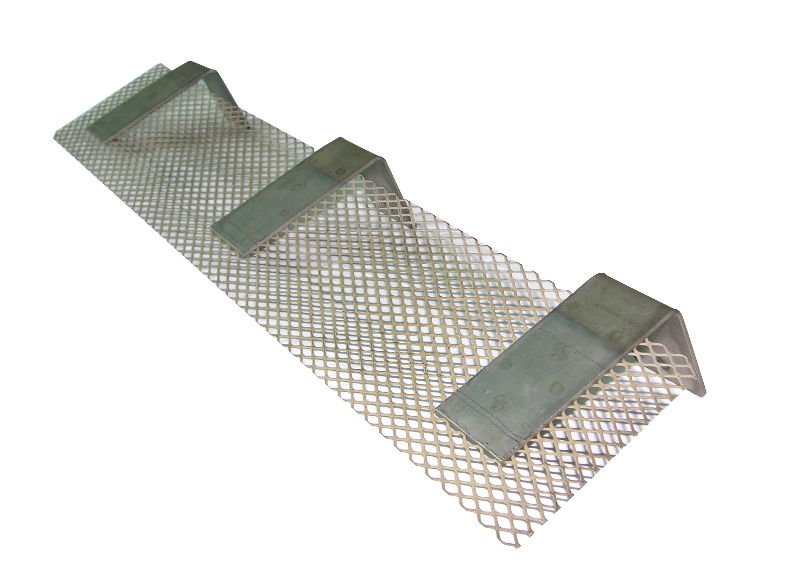

Production

Brush coating.

Specific operation as follows:

Firstly,making the coating solution according to the type and the area of the platinum electrode; secondly ,put the solution on the surface evenly, then put them into the drying furance for drying; thirdly,we need to oxidate in the high temperature oxidation furance;Lastly, dry it to room temperature. Then,repeat these steps until you run out the configuration solution.

Certification

Qixin is ISO 9001:2015 certified and own more than 10 patents. All its processes and procedures are documented and controlled in accordance with these standard. Qixin has strict product quality control procedure, from raw material to finished product, all the process is tested qualified to assure high quality product.

With technical engineers experienced for more than 18 years of constant research and production for titanium electrode and its application in various industries, Qixin can offer a very high level of technical support and products, which are among its most remarkable characteristics.

FAQ

1. How to ensure the product quality?

All products make 100% inspection before shipment also we can provide the MTC Material Test Certification.

2. Can you print our Logo on the products?

Sure, and we welcome the customerized products.

3.What about the payment terms?.

T/T, L/C, Paypal, Western Union, Escrew and MoneyGram etc are all accepted.

4.What is the necessary information for an inquiry?

Product name, specification, material grade and quantity.

5.Can we get a free sample before cargo production?

Sure.