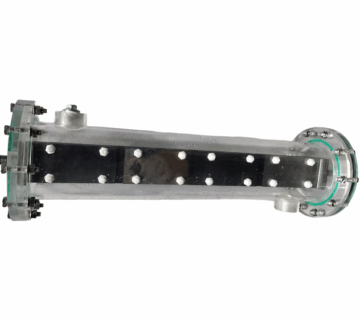

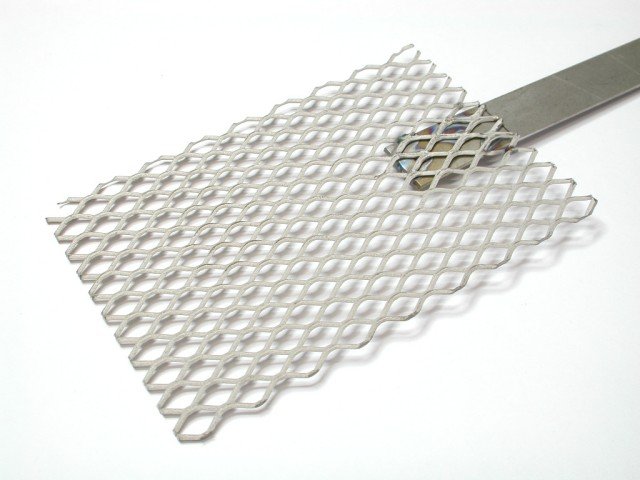

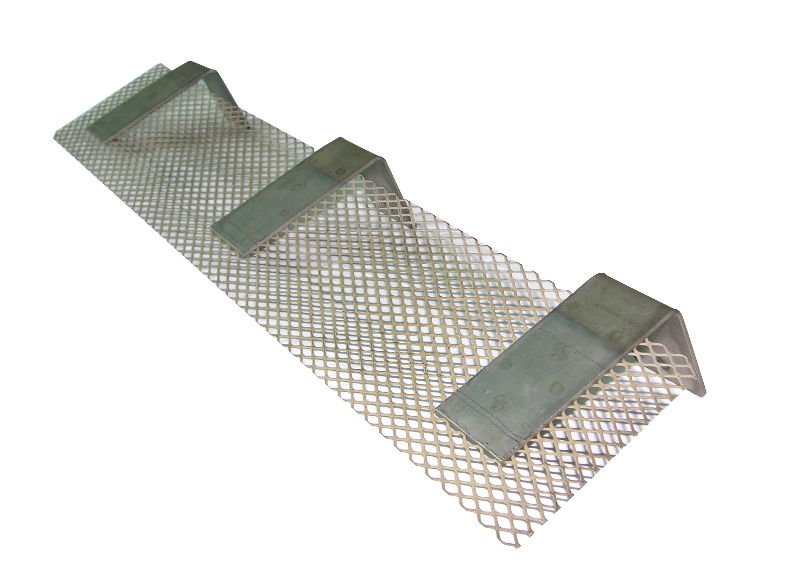

Platinum-coated titanium anodes consist of a high-purity titanium substrate (Grade 1/2) with a thin platinum layer (0.5–3 μm) applied via electroplating or physical vapor deposition. Designed for persulfate synthesis, these anodes catalyze the oxidation of sulfate ions (SO₄²⁻) to persulfate (S₂O₈²⁻) in electrolytic cells, leveraging platinum’s high electrocatalytic activity and titanium’s corrosion resistance.

Advantages:

High Catalytic Efficiency: Platinum lowers the overpotential for sulfate oxidation, enabling persulfate yields of 85–90% at current densities of 20–50 A/dm²—far exceeding graphite or MMO anodes (50–60% yield).

Corrosion Resistance: Titanium withstands aggressive acidic electrolytes (1–3 M H₂SO₄) and high temperatures (60–80°C), ensuring stable operation for 3–5 years.

Pure Product Output: Minimal metal leaching preserves persulfate purity (99.5%+), critical for applications in water treatment and chemical synthesis.

Energy Efficiency: Reduces cell voltage by 0.5–1.0 V compared to traditional anodes, cutting energy consumption by 15–25%.

Company Profile

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

production

1. Substrate treatment: it needs to be treated by roughing, cleaning and removing oil, which can increase the compactness of catalytic.

2. Brushing coating:After substrate treatment, it will be proceeded brush coated. The main coated content is platinum group metal, which is a kind of mixed solution.Then, heat treatment will be going on after drying.The whole procedure need to be repeated many times. This method is better to form thin oxide catalytic that is lamellar adhere to substrate surface.

Certification

Qixin is ISO 9001:2015 certified and own more than 10 patents. All its processes and procedures are documented and controlled in accordance with these standard. Qixin has strict product quality control procedure, from raw material to finished product, all the process is tested qualified to assure high quality product.

With technical engineers experienced for more than 18 years of constant research and production for titanium electrode and its application in various industries, Qixin can offer a very high level of technical support and products, which are among its most remarkable characteristics.

Our Happy Clients