Platinum coated titanium anodes optimize water ionizer performance by balancing corrosion resistance, catalytic efficiency, and safety, making them ideal for applications where water purity, energy savings, and long-term reliability are non-negotiable. Their ability to deliver consistent alkaline/acidic water while adhering to strict health and environmental standards solidifies their role as a premium choice in electrolysis-based water treatment.

Technical Specifications and Customization

Advantages

1. Exceptional Corrosion Resistance

Titanium Substrate: Forms a passive, self-repairing oxide layer (TiO₂) that resists degradation in acidic/alkaline environments and chloride-rich waters (e.g., tap water with residual chlorine).

Platinum Coating: Chemically inert and non-reactive with electrolytes or byproducts (e.g., Cl₂, O₂), ensuring no corrosion or metal leaching into the water.

Impact: Extends anode lifespan (2–10+ years) and maintains water purity, critical for health-focused applications.

2. High Catalytic Activity

Low Overpotential: Platinum lowers the energy barrier for key reactions like oxygen evolution (OER) and ion separation, reducing power consumption by 10–20% compared to less efficient materials (e.g., PbO₂).

Rapid Ionization: Facilitates fast separation of H⁺/OH⁻ ions, enabling stable pH gradients (alkaline: pH 8–11; acidic: pH 2.7–5.5) and high oxidation-reduction potential (ORP) values for effective disinfection.

Impact: Efficiently generates alkaline (health-focused) and acidic (disinfectant) water with minimal energy waste.

3. Longevity and Cost-Effectiveness

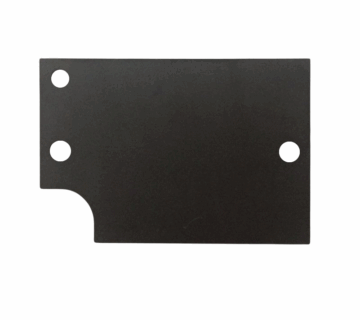

Durable Coating: Platinum coatings (0.5–10 microns) adhere tightly to titanium, resisting delamination even under high current density (up to 10,000 A/m²).

Recoatability: Titanium substrates can be stripped and recoated at 30–50% of the cost of a new anode, extending service life and reducing waste.

Impact: Lower long-term maintenance costs compared to disposable anodes (e.g., stainless steel) or less durable coatings.

4. Safety and Purity Assurance

No Contamination: Platinum’s inertness ensures zero metal ions (e.g., Ti, Pt) leach into the water, meeting strict food-grade standards (e.g., EU EC-1935-2004, NSF/ANSI 61).

Hypochlorous Acid (HOCl) Formation: Catalyzes the production of safe, natural disinfectants (HOCl, H₂O₂) without harsh chemicals, ideal for household use.

Impact: Provides clean, sterilized water suitable for drinking, cooking, and sanitization.

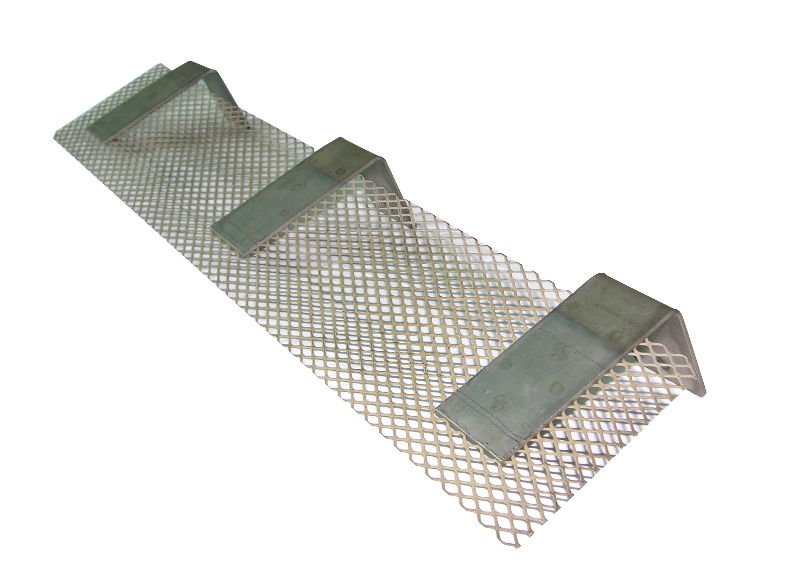

5. Operational Efficiency and Versatility

High Current Density: Maintains consistent performance at up to 2,000 A/m², enabling rapid electrolysis and high water flow rates.

Adaptability: Works across a wide pH range (2.7–12) and temperatures (<80°C), suitable for both residential ionizers and industrial systems (e.g., HOCl generators).

Anti-Scaling Design: Reverse polarity operation prevents calcium/magnesium scaling on the anode surface, minimizing maintenance downtime.

Impact: Reliable performance in diverse water qualities without frequent cleaning or recalibration.

6. Environmental and Regulatory Compliance

RoHS/REACH Compliance: Free of hazardous materials (e.g., lead, cadmium), aligning with global environmental standards.

Energy Efficiency: Reduces carbon footprint via low power consumption, appealing to eco-conscious consumers and industries.

Impact: Supports sustainable water treatment solutions.

7. Superior Performance vs. Alternatives

Compared to other anodes (e.g., ruthenium-iridium, stainless steel):

Platinum-Titanium excels in low-energy, high-purity applications (e.g., drinking water ionization) due to its unmatched catalytic efficiency and inertness.

Ruthenium-Iridium is better suited for high-chlorine environments (e.g., seawater) but lacks platinum’s purity and low overpotential for delicate ion separation.

Platinum coated titanium anode in Water Ionizer Electrolysis

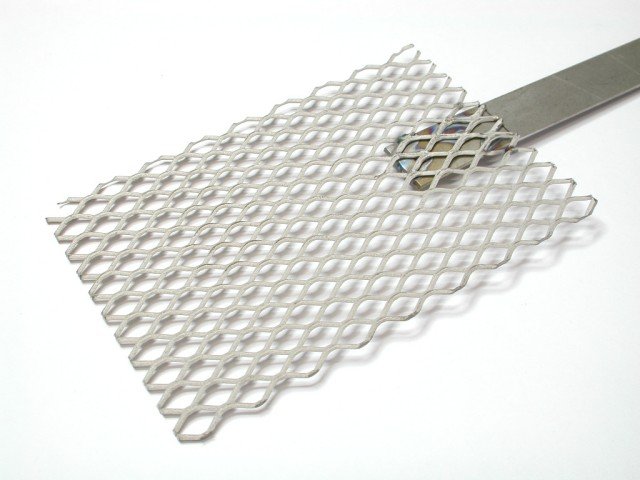

Generation of Alkaline and Acidic Ionized Water: During the electrolysis of tap water, positively charged ions such as potassium, sodium, calcium, and magnesium in the water flow toward the cathode to form alkaline ionized water, while negatively charged ions such as chlorine, sulfur, and phosphorus flow toward the anode to form acidic electrolytic water. The platinum – coated titanium anode plays a key role in this process, facilitating the separation and migration of ions to generate the desired ionized water.

Sterilization and Disinfection: The electrolysis process can produce substances with strong oxidizing properties, such as hypochlorite, nascent oxygen, and hydroxyl radicals, which can kill microorganisms and play a role in sterilization and disinfection. The platinum – coated titanium anode promotes the generation of these substances, making the electrolyzed water have good sterilization and disinfection effects, which is beneficial for improving water quality.

Who we are?

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

Production

Brush coating.

Specific operation as follows:

Firstly,making the coating solution according to the type and the area of the platinum electrode; secondly ,put the solution on the surface evenly, then put them into the drying furance for drying; thirdly,we need to oxidate in the high temperature oxidation furance;Lastly, dry it to room temperature. Then,repeat these steps until you run out the configuration solution.

Package and shipping

(The picture is for your reference) Customized Package Is Available.

Step1: Wrapped by water proof paper

Step2: Bubble papaer

Step3: Plywood case outside to avoid any damage during the shipment.

Or packed as customer’s requirement.

Shipping :by air,by sea,Ems,Fedex or Dhl.

Delivery:15 working days after payment.

Quality assurance and after-sales service

1. We promise that our substrate is high quality,acceleratd life test.The coating solution is configured according to the certain proportion.

2. With the high technology and equipment,All of our tecnical personnel have abundant experience,and our workers are very skilled.During the production of the Titanium anode, each process must carry on the strict examination,Such as the detection of surface rougghness,The quality of coating solution,coating evenness and so on.

3. We have our own production,sales and after-service department.We are usually dedicated to provide customers with high quality and reasonable price product.Most importantly ,we can provide the efficient service.

4. Each procedure will be carefully detected in the technical staff to compelete.accomplish the order in time and delivery on time.

5. During our cooperation,if you have any problem ,you can contact us at anytime,we will do our best to help you.

Our Happy Clients