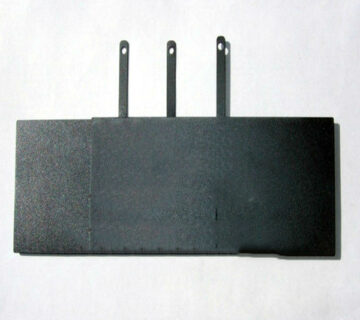

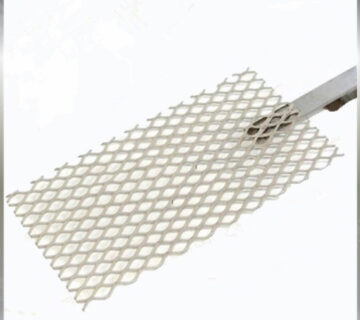

A platinized titanium anode consists of a titanium substrate coated with a thin layer of platinum. Titanium, known for its high strength to weight ratio and excellent corrosion resistance, serves as an ideal base material. It can withstand the harsh environments of both acidic and alkaline electrolytes used in hydrogen production. The platinum coating, typically ranging from a few micrometers to tens of micrometers in thickness, is applied through methods such as electroplating or chemical vapor deposition. Platinum, a precious metal, is renowned for its outstanding electrocatalytic properties, making it highly effective in facilitating the electrochemical reactions necessary for hydrogen evolution.

Electrocatalytic Mechanism in Hydrogen Production

Alkaline Electrolysis:In alkaline electrolyzers (using KOH/NaOH electrolytes), the platinized titanium anode catalyzes water oxidation:2H2O→O2 +4H + +4e −

Platinum reduces the overpotential required for this reaction, minimizing energy loss and enhancing efficiency.

Proton-Exchange Membrane (PEM) Electrolysis:In acidic PEM systems, the anode reaction remains water oxidation:2H2O→O2 +4H + +4e −

Here, platinum’s high activity for the oxygen evolution reaction (OER) enables operation at high current densities (1–3 A/cm²), supporting compact, high-throughput hydrogen production.

Advantages of Platinized Titanium Anodes

High Catalytic Activity

Platinum’s unique d-band structure optimizes reaction kinetics, achieving near-ideal overpotentials (<20 mV at 10 mA/cm² in acidic media). This reduces cell voltage by 0.2–0.3V compared to non-precious metal anodes, translating to 10–15% energy savings in industrial systems.

Corrosion Resistance

Titanium’s passive oxide layer resists degradation in both acidic (PEM) and alkaline (AWE) electrolytes. A 2023 case study showed platinized titanium anodes maintained 95% activity after 8 years in a 30% KOH solution, outperforming nickel-plated steel by 200%.

Long Service Life

With proper maintenance (e.g., periodic citric acid flushing), these anodes can operate for 5–8 years. Plug Power’s alkaline electrolysis plants demonstrate <5% performance decay over 10,000 cycles, reducing replacement costs by 70%.

Application

Large-Scale Hydrogen Production

Chemical Industry: In ammonia synthesis, platinized titanium anodes in 10 MW AWE plants produce 99.9% pure hydrogen at 400 mA/cm², supporting 500 tons/day output.

Refining: PEM electrolyzers with Pt/Ti anodes supply high-purity hydrogen for hydrocracking, achieving 99.99% purity at 2.5 A/cm² (Norsk Hydro pilot data).

Renewable Energy Integration

SunHydrogen’s solar-driven PEM system pairs platinized titanium anodes with perovskite cells, achieving 18% energy conversion efficiency for off-grid hydrogen production.

Why choose us?

1. Superior Material Quality & Durability

Corrosion Resistance: Titanium’s inherent resistance to acids, alkalis, and chloride-rich environments ensures long service life in demanding applications like cobalt electrowinning or wastewater treatment.

High Strength & Stability: Titanium maintains structural integrity under high currents and temperatures, reducing the risk of deformation or degradation.

Customized Coatings: We apply advanced oxide coatings (e.g., ruthenium, iridium, platinum group metals) tailored to your process, enhancing conductivity, catalytic activity, and longevity.

2. Technical Expertise & Custom Solutions

Tailored Design: We analyze your process parameters (current density, electrolyte composition, temperature) to design anodes that maximize efficiency.

R&D-Driven Innovation: Our team stays ahead of industry trends, integrating the latest coating technologies (e.g., mixed metal oxides, dimensionally stable anodes – DSAs) for performance gains.

Testing & Validation: Pre-production prototypes undergo rigorous testing to ensure compliance with your specifications.

3. Cost-Effectiveness & Sustainability

Lower Total Cost of Ownership (TCO):

Longevity reduces replacement frequency compared to traditional anodes (e.g., lead, graphite).

Energy-efficient designs cut electricity costs in large-scale operations.

Eco-Friendly: Titanium is recyclable, and our coatings minimize metal leaching, aligning with environmental regulations.

4. Reliable Service & Support

Global Supply Chain: Timely delivery through the streamlined manufacturing and logistics network.

Technical Support: Post-installation guidance, troubleshooting, and maintenance recommendations.

Compliance Assurance: Anodes meet international standards (e.g., ISO, SGS) and can be certified for specific industries (e.g., mining, water treatment).

Company Profile

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

production

1. Substrate treatment: it needs to be treated by roughing, cleaning and removing oil, which can increase the compactness of catalytic.

2. Brushing coating:After substrate treatment, it will be proceeded brush coated. The main coated content is platinum group metal, which is a kind of mixed solution.Then, heat treatment will be going on after drying.The whole procedure need to be repeated many times. This method is better to form thin oxide catalytic that is lamellar adhere to substrate surface.

FAQ

1. How to ensure the product quality?

All products make 100% inspection before shipment also we can provide the MTC Material Test Certification.

2. Can you print our Logo on the products?

Sure, and we welcome the customerized products.

3.What about the payment terms?.

T/T, L/C, Paypal, Western Union, Escrew and MoneyGram etc are all accepted.

4.What is the necessary information for an inquiry?

Product name, specification, material grade and quantity.

5.Can we get a free sample before cargo production?

Sure.