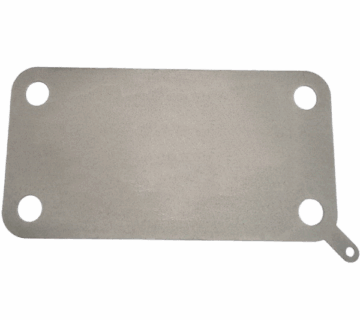

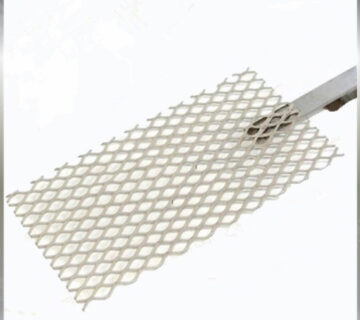

MMO (Metal Oxide Coated) titanium anodes for electrolytic dialysis refer to specialized electrodes comprising a titanium base material coated with a nanostructured layer of mixed metal oxides—typically ruthenium (Ru), iridium (Ir), tantalum (Ta), and titanium (Ti) oxides. Engineered for electrochemical separation processes, these anodes facilitate the oxygen evolution reaction (OER) at the anode side of electrodialysis systems, generating the electric field necessary to drive ions through cation/anion-exchange membranes. Their composite oxide coatings offer dual advantages: exceptional resistance to corrosion in acidic, alkaline, and chloride-rich electrolytes (pH 1–14), and low overpotential for OER (250–350 mV), which minimizes energy consumption while maintaining high current efficiency (up to 95%). With service lives ranging from 3 to 5 years—significantly longer than traditional graphite or metal anodes—MMO titanium anodes are pivotal in industrial applications requiring continuous, reliable ion separation, such as brackish water desalination, heavy metal wastewater treatment, and food-grade whey purification.

Advantages of MMO Titanium Anodes for Electrolytic Dialysis

Exceptional Corrosion Resistance

Withstands harsh environments (pH 1–14) and chloride-rich solutions (up to 10,000 ppm Cl⁻), outlasting stainless steel anodes by 8x in saltwater systems.

Coatings (e.g., RuO₂-Ta₂O₅ for acidic, IrO₂-TiO₂ for alkaline) form passive oxide layers to prevent substrate degradation.

Low Energy Consumption

Reduces oxygen evolution overpotential to 250–350 mV (30–50% lower than graphite), cutting energy use by 15–18% in desalination applications.

Enables high current densities (up to 200 mA/cm²) with minimal voltage loss.

Long Service Life

Operates for 3–5 years without performance decay in typical electrolytic dialysis setups, versus 1–2 years for graphite anodes.

Low maintenance requirements (periodic citric acid flushing to remove mineral deposits).

Environmental Safety

Free of toxic heavy metals (unlike lead anodes), compliant with strict wastewater discharge regulations.

Recyclable coating materials (e.g., ruthenium, iridium) via professional recovery processes.

Application Industries

1. Water Treatment & Desalination

Brackish Water Desalination:Used in electro dialysis (ED) plants to convert 2,000 ppm NaCl water to <500 ppm, as seen in a 5,000 m³/day Middle Eastern facility with 4-year anode lifespan.

Seawater Desalination:Enhances energy efficiency in ED reverse osmosis (EDRO) systems, reducing specific energy consumption to <1.5 kWh/m³.

2. Industrial Wastewater Management

Heavy Metal Removal:Electrolytic dialysis with IrO₂-Ta₂O₅/titanium anodes achieves 99.5% Cr⁶⁺ removal from pharmaceutical wastewater at pH 2–3.

Zero Liquid Discharge (ZLD):Processes industrial brines in mining and petrochemical sectors, recovering valuable salts while minimizing discharge.

3. Food & Beverage Industry

Whey Desalination:Maintains 90% current efficiency in alkaline conditions (pH 8–9) for cheese production, ensuring no metal ion contamination in food products.

Process Water Purification:Removes salts from beverage manufacturing streams to meet strict quality standards.

4. Chemical & Petrochemical Sectors

Electrolyte Regeneration:Reclaims acids and bases in chemical synthesis, such as sulfuric acid recovery in battery recycling.

Catalyst Production:Supports electrodialysis for high-purity electrolyte preparation in catalyst manufacturing.

5. Electronics & Semiconductor Manufacturing

Ultra-Pure Water Production:Used in ED systems to remove trace ions from rinse waters, critical for semiconductor wafer fabrication.

Waste Etchant Recovery:

Recovers valuable metals (e.g., copper, nickel) from electronic waste etching solutions.

Who we are?

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

Production

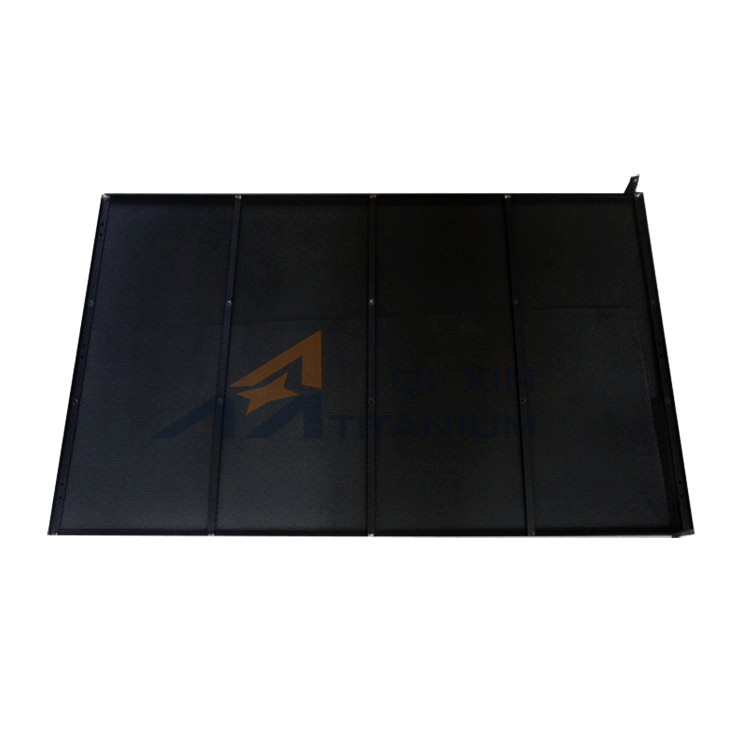

Brush coating.

Specific operation as follows:

Firstly,making the coating solution according to the type and the area of the platinum electrode; secondly ,put the solution on the surface evenly, then put them into the drying furance for drying; thirdly,we need to oxidate in the high temperature oxidation furance;Lastly, dry it to room temperature. Then,repeat these steps until you run out the configuration solution.

Certification

Qixin is ISO 9001:2015 certified and own more than 10 patents. All its processes and procedures are documented and controlled in accordance with these standard. Qixin has strict product quality control procedure, from raw material to finished product, all the process is tested qualified to assure high quality product.

With technical engineers experienced for more than 18 years of constant research and production for titanium electrode and its application in various industries, Qixin can offer a very high level of technical support and products, which are among its most remarkable characteristics.

FAQ

1. How to ensure the product quality?

All products make 100% inspection before shipment also we can provide the MTC Material Test Certification.

2. Can you print our Logo on the products?

Sure, and we welcome the customerized products.

3.What about the payment terms?.

T/T, L/C, Paypal, Western Union, Escrew and MoneyGram etc are all accepted.

4.What is the necessary information for an inquiry?

Product name, specification, material grade and quantity.

5.Can we get a free sample before cargo production?

Sure.