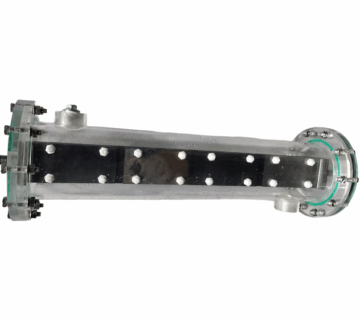

MMO (Mixed Metal Oxide) titanium anodes are electrode materials with titanium as the substrate and a surface coating of mixed metal oxides (such as iridium, ruthenium, and platinum). They are widely used in electro-catalytic oxidation wastewater treatment due to their excellent electro-catalytic activity and corrosion resistance.In the electro-catalytic oxidation wastewater treatment process, the MMO titanium anode acts as the anode. Under the action of a DC electric field, water molecules undergo electrochemical reactions on its surface, generating reactive oxygen species (ROS) such as hydroxyl radicals (·OH), ozone (O₃), and hypochlorite ions (ClO⁻).These reactive oxygen species have strong oxidizing properties, which can oxidize and decompose pollutants in wastewater—including organic compounds, cyanides, and heavy metal ions—into harmless substances.

Advantages

1. Strong Corrosion Resistance

The dense oxide film on the titanium substrate and the coated mixed metal oxide layer enable the MMO titanium anode to remain stable in harsh wastewater environments (e.g., strong acids, strong alkalis, and high salinity). It is not easily corroded, with a typical service life of 3–5 years—far longer than traditional anode materials like graphite or lead.

2.High Electro-Catalytic Efficiency

The MMO coating has excellent electro-catalytic activity, which significantly reduces the overpotential for oxygen evolution and chlorine evolution, thereby improving the efficiency of electrolytic reactions. For instance, the addition of RuO₂ lowers the oxygen evolution overpotential from 1.6V to 1.3V, reducing the operating voltage by 30% under the same current density and effectively cutting energy consumption.

3. Environmental Friendliness

No chemical agents are added during the electrolysis process, avoiding secondary pollution that may occur with traditional chemical treatment methods. Moreover, the reactive oxygen species generated by electro-catalytic oxidation can effectively degrade pollutants in wastewater, reducing pollutant emissions and meeting environmental discharge standards.

4.High Current Density Tolerance

Compared with traditional anode materials (e.g., graphite, lead), MMO titanium anodes can withstand higher current densities (up to 2000 A/m²). Within the same electrolytic cell volume and treatment time, they can process more wastewater, significantly improving treatment efficiency.

Application Scenarios

1.Cyanide-Containing Wastewater Treatment

Common in industries such as electroplating and mining, cyanide-containing wastewater is highly toxic. The MMO titanium anode uses electrolytic oxidation to decompose cyanides into harmless substances (N₂ and CO₂), achieving the harmless treatment of cyanide-containing wastewater.

2.Phenol-Containing Wastewater Treatment

Phenol-containing wastewater (from petrochemical, coking, and pharmaceutical industries) is difficult to biodegrade. Through electro-catalytic oxidation, the MMO titanium anode effectively degrades phenolic compounds, reducing the phenol content in wastewater to meet discharge standards.

3.High-Salinity Wastewater Treatment

High-salinity wastewater (e.g., from chemical engineering, mariculture) often contains high concentrations of Cl⁻. The MMO titanium anode can generate chlorine gas (Cl₂) and sodium hydroxide (NaOH) through electrolysis, realizing integrated desalination and disinfection of wastewater. At the same time, it can oxidize and remove organic compounds and other pollutants in the water.

4.Refractory Organic Wastewater Treatment

For wastewater containing refractory organics (e.g., dyes, pharmaceuticals, and pesticides), the MMO titanium anode breaks the stable chemical bonds of organic molecules via strong oxidizing reactive oxygen species, improving the biodegradability of wastewater (increasing B/C ratio from <0.2 to >0.3) and creating conditions for subsequent biological treatment.

Who we are

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

Production

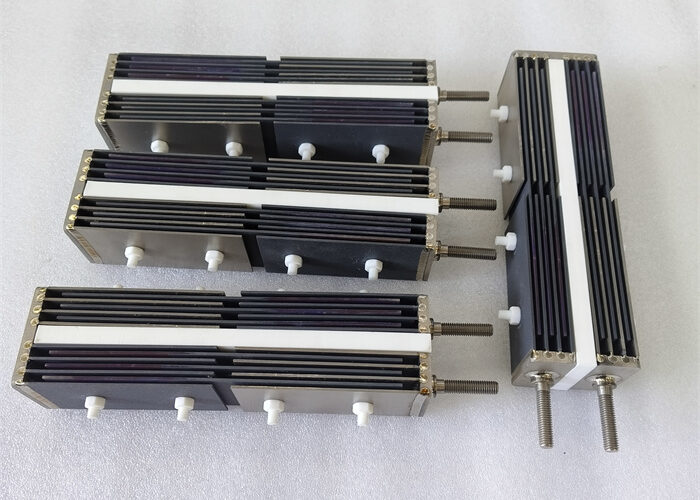

1. Substrate treatment: it needs to be treated by roughing, cleaning and removing oil, which can increase the compactness of catalytic.

2. Brushing coating:After substrate treatment, it will be proceeded brush coated. The main coated content is platinum group metal, which is a kind of mixed solution.Then, heat treatment will be going on after drying.The whole procedure need to be repeated many times. This method is better to form thin oxide catalytic that is lamellar adhere to substrate surface.

Why Choose Us?

Unrivaled Product Quality

Crafted from premium titanium with precision and strict quality control, our anodes use advanced coating methods like thermal decomposition. Catalytic layers such as RuO₂-IrO₂ or SnO₂-Sb₂O₃ boost corrosion resistance, electrochemical activity, and lifespan.

Exceptional Performance

With low overpotential, our anodes cut energy use by up to 30% in electrochemical oxidation. High current efficiency enables fast degradation of organic pollutants, heavy metals, and PFAS across various wastewater types.

Customized Solutions

We customize anode coating, thickness, and structure. Our experts analyze your project to ensure cost-effective, optimized performance.

Extensive Industry Experience

Years of work in textiles, pharmaceuticals, and mining give us deep expertise for proactive problem-solving.

Comprehensive Technical Support

Our support covers installation, maintenance, troubleshooting, and staff training.

Sustainable and Environmentally Friendly

Designed to reduce energy use and heavy metal release, our anodes prioritize sustainability, with ongoing R&D for improvements.

Competitive Pricing

Despite top quality, optimized processes and supply chains make our anodes affordable.

Choose us for superior quality, performance, and service. Contact us to achieve your wastewater treatment goals.

Quality assurance and after-sales service

1. We promise that our substrate is high quality,acceleratd life test.The coating solution is configured according to the certain proportion.

2.With the high technology and equipment,All of our tecnical personnel have abundant experience,and our workers are very skilled.During the production of the Titanium anode, each process must carry on the strict examination,Such as the detection of surface rougghness,The quality of coating solution,coating evenness and so on.

3.We have our own production,sales and after-service department.We are usually dedicated to provide customers with high quality and reasonable price product.Most importantly ,we can provide the efficient service.

4.Each procedure will be carefully detected in the technical staff to compelete.accomplish the order in time and delivery on time.

5.During our cooperation,if you have any problem ,you can contact us at anytime,we will do our umost to help you.