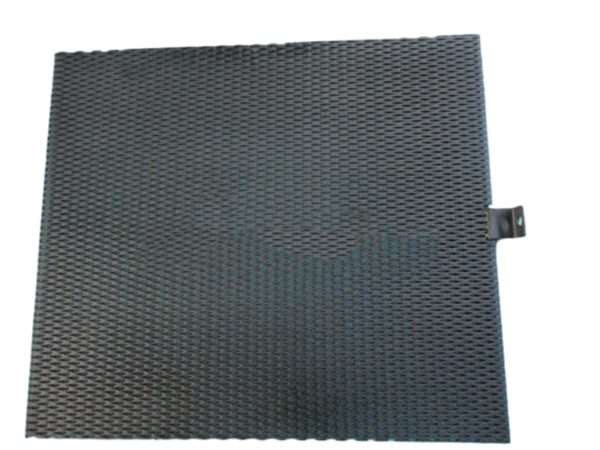

In electrowinning cells, MMO (Mixed Metal Oxide)-coated anodes play a pivotal role in efficiently extracting metals from electrolytes.

1.Anodic Reaction (Oxygen Evolution):

The MMO anode catalyzes the oxidation of water to produce oxygen gas, a reaction critical for metal deposition at the cathode. The general equation is:2H2O−4e−⟶O2↑+4H+

MMO coatings (e.g., mixtures of IrO₂, RuO₂, TiO₂, or SnO₂) enhance this reaction by lowering the overpotential required for oxygen evolution, making it more energy-efficient than traditional anodes (e.g., lead alloys or graphite).

2.Cathodic Reaction (Metal Deposition):

Metal ions are reduced at the cathode, forming a solid deposit. For example, in copper electrowinning:Cu2++2e−⟶Cu

Advantages of MMO Anodes in Electrowinning

1. Low Overpotential & Energy Savings

MMO anodes exhibit overpotentials 300–600 mV lower than lead-based anodes in acidic electrolytes. For instance, in zinc electrowinning, this reduces cell voltage by ~0.5 V, leading to 10–15% energy savings.

Lower overpotential minimizes heat generation, reducing cooling requirements and improving process stability.

2. High Corrosion Resistance & Longevity

The oxide coating protects the titanium substrate from acidic or corrosive electrolytes (e.g., sulfuric acid in Zn/Cu electrowinning or chloride solutions in Ni electrowinning).

Service life typically ranges from 3 to 8 years, depending on the metal and conditions (e.g., 5 years in zinc cells, 3–4 years in high-current-density copper cells).

3. Enhanced Metal Purity

MMO anodes minimize side reactions (e.g., chlorine evolution or anode dissolution), which can introduce impurities. This ensures higher-purity metal deposits (e.g., 99.99% Cu or Zn).

In copper electrowinning, reduced anode corrosion prevents lead or other contaminants from entering the electrolyte, improving cathode quality.

4. Environmental & Operational Benefits

MMO anodes produce only oxygen as a byproduct, avoiding toxic emissions (e.g., chlorine from graphite anodes in chloride systems).

Their smooth surface reduces sludge formation, simplifying electrolyte maintenance and lowering waste disposal costs.

Application in Different Electrowinning Processes

1. Zinc Electrowinning

Electrolyte: Acidic zinc sulfate (ZnSO₄ + H₂SO₄).

MMO Coating: Typically RuO₂-TiO₂ or IrO₂-Ta₂O₅ on titanium.

Current Density: 100–800 A/m² (optimal ~300–500 A/m²).

Impact: Replaces Pb-Ag anodes, reducing lead contamination in the electrolyte and improving zinc purity (99.995% Zn).

2. Copper Electrowinning

Electrolyte: Acidic copper sulfate (CuSO₄ + H₂SO₄).

MMO Coating: IrO₂-SnO₂ or RuO₂-SnO₂ for high stability in sulfuric acid.

Current Density: 200–1000 A/m² (common ~300–600 A/m²).

Impact: Enables higher current densities than graphite anodes, increasing production efficiency while maintaining 99.99% Cu purity.

3. Nickel Electrowinning

Electrolyte: Chloride-based (NiCl₂) or sulfate-chloride mixtures.

MMO Coating: IrO₂-Ta₂O₅ or IrO₂-RuO₂ for resistance to chloride-induced corrosion.

Current Density: 150–500 A/m².

Impact: Replaces insoluble anodes (e.g., graphite), reducing chlorine gas evolution and improving nickel purity (99.99% Ni).

| Parameter | Zinc Electrowinning | Copper Electrowinning | Nickel Electrowinning |

|---|---|---|---|

| Current Density | 100–800 A/m² (optimal: 300–500 A/m²) | 200–1000 A/m² (common: 300–600 A/m²) | 150–500 A/m² |

| Electrolyte Composition | ZnSO₄ (50–80 g/L Zn²⁺) + H₂SO₄ (150–200 g/L) | CuSO₄ (30–50 g/L Cu²⁺) + H₂SO₄ (180–220 g/L) | NiCl₂ (80–120 g/L Ni²⁺) or NiSO₄-NiCl₂ mixture |

| pH Range | 1–4 (acidic) | 1–3 (acidic) | 1–5 (acidic in chloride systems) |

| Temperature | 40–55°C | 50–60°C | 50–70°C |

| Key Impurity Limits | – Cl⁻ < 50 ppm – Fe, Co, Ni < 10 ppm |

– Cl⁻ < 50 ppm – Fe, As, Sb < 5 ppm |

– Cl⁻ (controlled for stability) – Heavy metals < 5 ppm |

| Electrolyte Circulation | Continuous agitation to maintain ion uniformity | Continuous agitation to prevent concentration polarization | Continuous stirring or pumping |

| Anode Coating Type | RuO₂-TiO₂ or IrO₂-Ta₂O₅ | IrO₂-SnO₂ or RuO₂-SnO₂ | IrO₂-Ta₂O₅ or IrO₂-RuO₂ |

| Coating Thickness | 5–20 μm | 5–15 μm | 8–20 μm |

Why Choose Us?

Unrivaled Product Quality

Crafted from premium titanium with precision and strict quality control, our anodes use advanced coating methods like thermal decomposition. Catalytic layers such as RuO₂-IrO₂ or SnO₂-Sb₂O₃ boost corrosion resistance, electrochemical activity, and lifespan.

Exceptional Performance

With low overpotential, our anodes cut energy use by up to 30% in electrochemical oxidation. High current efficiency enables fast degradation of organic pollutants, heavy metals, and PFAS across various wastewater types.

Customized Solutions

We customize anode coating, thickness, and structure. Our experts analyze your project to ensure cost-effective, optimized performance.

Extensive Industry Experience

Years of work in textiles, pharmaceuticals, and mining give us deep expertise for proactive problem-solving.

Comprehensive Technical Support

Our support covers installation, maintenance, troubleshooting, and staff training.

Sustainable and Environmentally Friendly

Designed to reduce energy use and heavy metal release, our anodes prioritize sustainability, with ongoing R&D for improvements.

Competitive Pricing

Despite top quality, optimized processes and supply chains make our anodes affordable.

Choose us for superior quality, performance, and service. Contact us to achieve your wastewater treatment goals.

Company profile

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

production

1. Substrate treatment: it needs to be treated by roughing, cleaning and removing oil, which can increase the compactness of catalytic.

2. Brushing coating:After substrate treatment, it will be proceeded brush coated. The main coated content is platinum group metal, which is a kind of mixed solution.Then, heat treatment will be going on after drying.The whole procedure need to be repeated many times. This method is better to form thin oxide catalytic that is lamellar adhere to substrate surface.

Package and shipping

(The picture is for your reference) Customized Package Is Available.

Step1: Wrapped by water proof paper

Step2: Bubble papaer

Step3: Plywood case outside to avoid any damage during the shipment.

Or packed as customer’s requirement.

Shipping :by air,by sea,Ems,Fedex or Dhl.

Delivery:15 working days after payment.