An MMO (Mixed Metal Oxide) anode, typically composed of ruthenium-iridium (RuO₂-IrO₂) or iridium-tantalum (IrO₂-Ta₂O₅) coatings on a titanium substrate, operates through electrochemical activation and indirect oxidation mechanisms to remove ammonia (NH₃/NH₄⁺) from wastewater.

Electrochemical ammonia removal primarily relies on chlorine-mediated oxidation when chloride ions (Cl⁻) are present in the wastewater. The process involves two key pathways:

1. Breakpoint Chlorination:

Chloride ions are oxidized at the MMO anode to form free chlorine (HOCl/OCl⁻).

HOCl reacts with ammonia (NH₃) to produce nitrogen gas (N₂) via sequential reactions.

2. Chlorine Radical Oxidation:

Under acidic conditions, MMO anodes generate chlorine radicals (Cl· and Cl₂·⁻), which directly oxidize NH₄⁺ to N₂ with higher efficiency.

The overall reaction efficiency is influenced by current density, Cl⁻ concentration, and pH, with optimal performance typically observed at pH 7–11 and current densities of 20–50 mA/cm²

Technical Considerations and Customization

1. Coating Composition

Ruthenium-iridium (RuO₂-IrO₂) coatings are preferred for ammonia removal due to their high activity in chlorine evolution and stability in acidic/alkaline media.

Customizable formulations (e.g., adding platinum or tantalum oxides) optimize performance for specific wastewater chemistries (e.g., high sulfate or heavy metal content).

2. Operational Parameters

Cl⁻ Concentration: Higher Cl⁻ levels (e.g., 50–100 mM) enhance free chlorine generation and ammonia oxidation rates

pH Control: Neutral to alkaline conditions (pH 7–11) favor breakpoint chlorination, while acidic pH (2–4) promotes chlorine radical pathways.

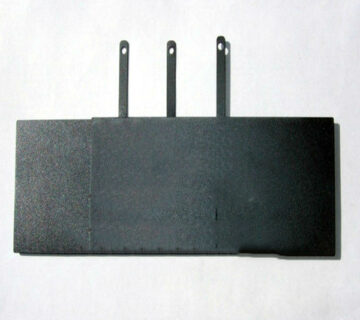

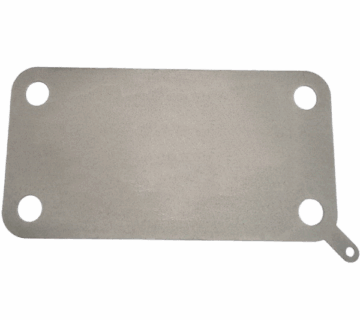

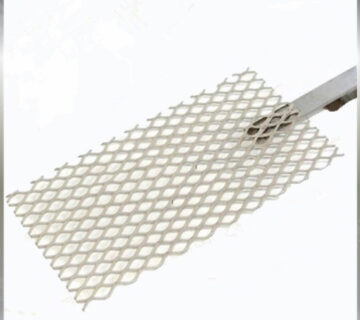

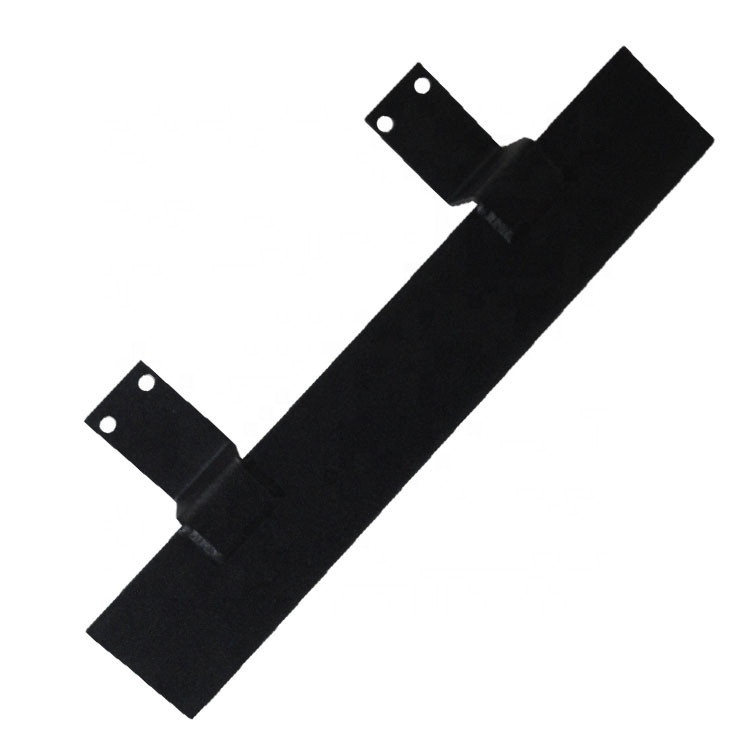

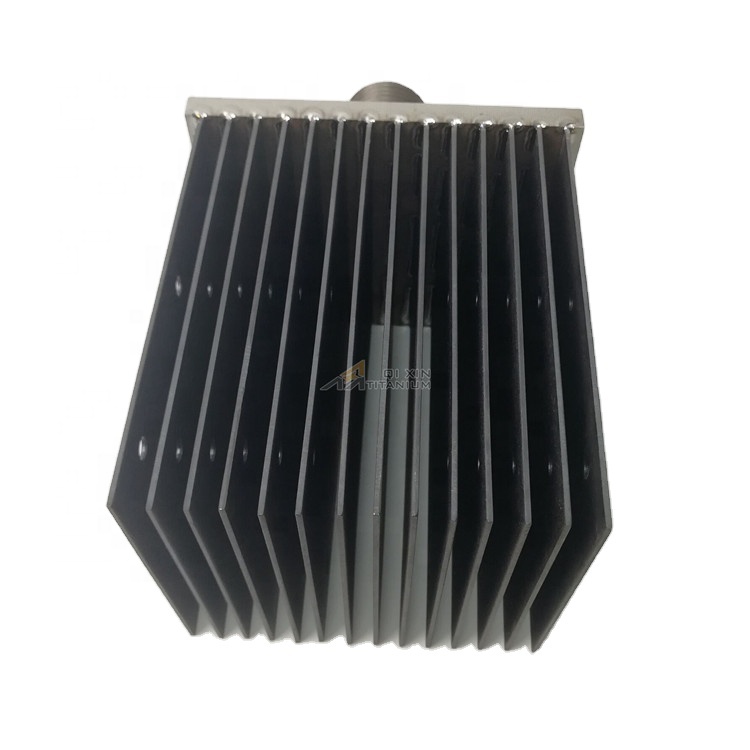

3. Anode Design

Plate, mesh, or tubular configurations adapt to complex reactor geometries, ensuring uniform current distribution.

Surface modifications (e.g., BiOCl-functionalization) increase active sites for Cl⁻ adsorption and radical production.

Applications

1. Industrial Wastewater:

Landfill Leachate: MMO anodes achieve >98% NH₄⁺-N removal in real landfill leachate with minimal chloramine formation, meeting strict discharge limits.

Spent Caustic Wastewater: Electrochemical treatment with MMO anodes removes 98.7% ammonia in 120 seconds at 4 A, suitable for high-alkalinity industrial effluents.

2. Municipal Wastewater:

Pre-treatment of anaerobic/aerobic reactor effluents reduces ammonia to <0.5 mg N/L within 2 hours, complying with stringent environmental standards.

3. Aquaculture and Swimming Pools:

MMO anodes efficiently remove ammonia and disinfect water through electrochlorination, ensuring safe aquatic environments.

Company Profile

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

production

1. Substrate treatment: it needs to be treated by roughing, cleaning and removing oil, which can increase the compactness of catalytic.

2. Brushing coating:After substrate treatment, it will be proceeded brush coated. The main coated content is platinum group metal, which is a kind of mixed solution.Then, heat treatment will be going on after drying.The whole procedure need to be repeated many times. This method is better to form thin oxide catalytic that is lamellar adhere to substrate surface.

Why Choose Us?

Unrivaled Product Quality

Crafted from premium titanium with precision and strict quality control, our anodes use advanced coating methods like thermal decomposition. Catalytic layers such as RuO₂-IrO₂ or SnO₂-Sb₂O₃ boost corrosion resistance, electrochemical activity, and lifespan.

Exceptional Performance

With low overpotential, our anodes cut energy use by up to 30% in electrochemical oxidation. High current efficiency enables fast degradation of organic pollutants, heavy metals, and PFAS across various wastewater types.

Customized Solutions

We customize anode coating, thickness, and structure. Our experts analyze your project to ensure cost-effective, optimized performance.

Extensive Industry Experience

Years of work in textiles, pharmaceuticals, and mining give us deep expertise for proactive problem-solving.

Comprehensive Technical Support

Our support covers installation, maintenance, troubleshooting, and staff training.

Sustainable and Environmentally Friendly

Designed to reduce energy use and heavy metal release, our anodes prioritize sustainability, with ongoing R&D for improvements.

Competitive Pricing

Despite top quality, optimized processes and supply chains make our anodes affordable.

Choose us for superior quality, performance, and service. Contact us to achieve your wastewater treatment goals.

Our Happy Clients