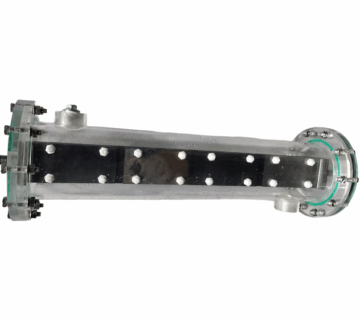

In salt water electrolysis—whether for chlorine production, sodium hypochlorite synthesis, or seawater treatment—DSA titanium electrodes serve as the anode, driving the critical oxidation of chloride ions (Cl-)):2Cl-=Cl2↑+2e- The chlorine gas generated further reacts with water to form hypochlorous acid (HClO) or hypochlorite ions (ClO-), key oxidizing agents for disinfection or chemical synthesis. Unlike traditional anodes (e.g., graphite), DSA titanium electrodes maintain their shape and performance over time, ensuring consistent reaction efficiency and reducing maintenance needs.

Titanium Substrate: High-purity titanium (GR1/GR2) provides a robust, corrosion-resistant base that withstands the aggressive, high-chloride environment of salt water. Its excellent conductivity ensures efficient current transfer to the coating.

Mixed Metal Oxide (MMO) Coating: The defining feature of DSA electrodes, the coating is typically a blend of noble metal oxides such as ruthenium oxide (RuO₂), iridium oxide (IrO₂), and tantalum oxide (TaO₂). This formulation:

Lowers the overpotential for chloride oxidation, reducing energy consumption.

Resists corrosion from chlorine and acidic byproducts, extending electrode life.

Enhances selectivity for chlorine evolution over unwanted reactions (e.g., oxygen evolution), maximizing target product yield.

Advantage

High Current Efficiency: Achieves 90–95% current efficiency for chlorine evolution, meaning most of the electrical energy is converted into the desired reaction rather than waste heat.

Stable Operating Parameters: Performs reliably at current densities of 1000–3000 A/m² and cell voltages of 2.5–4.0 V, suitable for both small-scale and industrial electrolyzers.

Long Service Life: In typical salt water electrolysis conditions, lifespan ranges from 3–7 years, far exceeding graphite anodes (6–12 months) or lead-based anodes (1–2 years).

Broad Compatibility: Works in brine (NaCl solutions), seawater, and brackish water, adapting to varying salinity levels (1–35 g/L Cl⁻) without performance degradation.

Applications in Salt Water Electrolysis

Chlor-Alkali Industry:

Central to the electrolysis of brine (saturated NaCl) for producing chlorine gas, sodium hydroxide (NaOH), and hydrogen. DSA electrodes here reduce energy use by 10–15% compared to older technologies.

Sodium Hypochlorite Generation:

Used in on-site electrolyzers to produce sodium hypochlorite (NaClO) from dilute salt water, a critical disinfectant for water treatment (municipal water, swimming pools, wastewater).

Seawater Treatment:

Integrated into marine systems (e.g., ship ballast water, offshore platforms) to electrolyze seawater, generating biocides that prevent biofouling and microbial growth.

Desalination Auxiliary:

Helps control membrane fouling in desalination plants by electrolyzing brine waste to produce chlorine, which sanitizes feed water and reduces organic contamination.

Why choose us?

1. Superior Material Quality & Durability

Corrosion Resistance: Titanium’s inherent resistance to acids, alkalis, and chloride-rich environments ensures long service life in demanding applications like cobalt electrowinning or wastewater treatment.

High Strength & Stability: Titanium maintains structural integrity under high currents and temperatures, reducing the risk of deformation or degradation.

Customized Coatings: We apply advanced oxide coatings (e.g., ruthenium, iridium, platinum group metals) tailored to your process, enhancing conductivity, catalytic activity, and longevity.

2. Technical Expertise & Custom Solutions

Tailored Design: We analyze your process parameters (current density, electrolyte composition, temperature) to design anodes that maximize efficiency.

R&D-Driven Innovation: Our team stays ahead of industry trends, integrating the latest coating technologies (e.g., mixed metal oxides, dimensionally stable anodes – DSAs) for performance gains.

Testing & Validation: Pre-production prototypes undergo rigorous testing to ensure compliance with your specifications.

3. Cost-Effectiveness & Sustainability

Lower Total Cost of Ownership (TCO):

Longevity reduces replacement frequency compared to traditional anodes (e.g., lead, graphite).

Energy-efficient designs cut electricity costs in large-scale operations.

Eco-Friendly: Titanium is recyclable, and our coatings minimize metal leaching, aligning with environmental regulations.

4. Reliable Service & Support

Global Supply Chain: Timely delivery through the streamlined manufacturing and logistics network.

Technical Support: Post-installation guidance, troubleshooting, and maintenance recommendations.

Compliance Assurance: Anodes meet international standards (e.g., ISO, SGS) and can be certified for specific industries (e.g., mining, water treatment).

Who we are ?

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

Certification

Qixin is ISO 9001:2015 certified and own more than 10 patents. All its processes and procedures are documented and controlled in accordance with these standard. Qixin has strict product quality control procedure, from raw material to finished product, all the process is tested qualified to assure high quality product.

With technical engineers experienced for more than 18 years of constant research and production for titanium electrode and its application in various industries, Qixin can offer a very high level of technical support and products, which are among its most remarkable characteristics.

FAQ

1. How to ensure the product quality?

All products make 100% inspection before shipment also we can provide the MTC Material Test Certification.

2. Can you print our Logo on the products?

Sure, and we welcome the customerized products.

3.What about the payment terms?.

T/T, L/C, Paypal, Western Union, Escrew and MoneyGram etc are all accepted.

4.What is the necessary information for an inquiry?

Product name, specification, material grade and quantity.

5.Can we get a free sample before cargo production?

Sure.