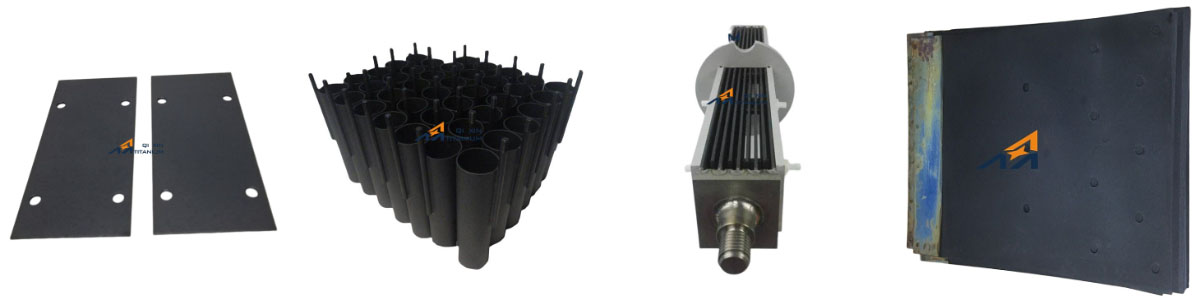

Product Introduction

DSA (Dimensionally Stable Anodes) titanium anodes represent a significant advancement in electrochemical technology, known for their superior performance and longevity. These anodes are crafted from high-quality titanium and specially coated to enhance their efficiency in a variety of applications, including electroplating, water treatment, and other electrochemical processes. By utilizing DSA titanium anodes, industries can improve operational efficiency and achieve higher production rates while maintaining environmental sustainability.

Key Features

1.Corrosion Resistance: DSA titanium anodes are engineered to resist corrosion, ensuring a long lifespan even in harsh environments.

2.Durability: Designed for longevity, these anodes can withstand extreme conditions, reducing the frequency of replacements.

3.Electrical Conductivity: High conductivity allows for efficient electron transfer, leading to enhanced performance in electrochemical applications.

Benifits

1.High anti-corrosion property

2.Lasting working life

3.Keep the operating voltage stably

4.High current efficiency

5.High catalytic property

Applications

| Application Field | Specific Scenarios | Typical Coating Systems | Core Advantages |

|---|---|---|---|

| Chlor-Alkali Industry | Chlorine and NaOH electrolysis | RuO₂-TiO₂, RuO₂-SnO₂ | Low energy consumption, long lifespan, high chlorine purity |

| Water Electrolysis for H₂ | Alkaline/PEM water electrolysis | IrO₂-Ta₂O₅, IrO₂-RuO₂ | High catalytic activity, acid/alkali resistance, high electrolysis efficiency |

| Metal Electrowinning/Refining | Zn, Cu, Ni electrowinning; precious metals | RuO₂-TiO₂, IrO₂-SnO₂ | High current efficiency (≥95%), reduced heavy metal pollution (e.g., replacing lead) |

| Wastewater Treatment | Ammonia nitrogen, organics, heavy metals removal | IrO₂-Ta₂O₅, SnO₂-Sb₂O₃ | Strong oxidation for pollutant degradation, no secondary pollution, adaptable to complex water quality |

| Cathodic Protection | Marine engineering, underground pipelines | IrO₂-Ta₂O₅, RuO₂-TiO₂ | Stable at low currents, corrosion resistance, long lifespan (≥10 years) |

| Electrochemical Synthesis | Organic electrosynthesis, chemical production | IrO₂-RuO₂, SnO₂-Sb₂O₃ | High reaction selectivity, customizable electrochemical |

Company Profile

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

production

1. Substrate treatment: it needs to be treated by roughing, cleaning and removing oil, which can increase the compactness of catalytic.

2. Brushing coating:After substrate treatment, it will be proceeded brush coated. The main coated content is platinum group metal, which is a kind of mixed solution.Then, heat treatment will be going on after drying.The whole procedure need to be repeated many times. This method is better to form thin oxide catalytic that is lamellar adhere to substrate surface.

Packing and shipping

(The picture is for your reference) Customized Package Is Available.

Step1: Wrapped by water proof paper

Step2: Bubble papaer

Step3: Plywood case outside to avoid any damage during the shipment.

Or packed as customer’s requirement.

Shipping :by air,by sea,Ems,Fedex or Dhl.

Delivery:15 working days after payment.

Quality assurance and after-sales service

1.We promise that our substrate is high quality,acceleratd life test.The coating solution is configured according to the certain proportion.

2.With the high technology and equipment,All of our tecnical personnel have abundant experience,and our workers are very skilled.During the production of the Titanium anode, each process must carry on the strict examination,Such as the detection of surface rougghness,The quality of coating solution,coating evenness and so on.

3.We have our own production,sales and after-service department.We are usually dedicated to provide customers with high quality and reasonable price product.Most importantly ,we can provide the efficient service.

4.Each procedure will be carefully detected in the technical staff to compelete.accomplish the order in time and delivery on time.

5.During our cooperation,if you have any problem ,you can contact us at anytime,we will do our umost to help you.

Contact Us

For more information or to request a quote, please reach out to us:

Email: info@mmo-anode.com

Phone: +86 9173307518, +86 18395477537, +86 13759759535, +86 18991769543, +86 15891475263

WhatsApp: +86 18395477537, +86 13759759535, +86 18991769543, +86 15891475263