In the realm of chlor-alkali production, the choice of electrode materials plays a pivotal role in determining process efficiency and overall productivity. Among the various options available, platinum plated titanium mesh electrodes have emerged as a game-changer, offering a trifecta of advantages that set them apart in this critical industry. These electrodes combine the structural integrity of titanium with the catalytic prowess of platinum, resulting in a robust and high-performing component for chlor-alkali cells. The top three benefits of utilizing platinum plated titanium mesh electrodes in chlor-alkali applications are their exceptional durability, superior electrical conductivity, and remarkable catalytic activity. These attributes collectively contribute to enhanced process efficiency, reduced energy consumption, and extended operational lifespan, making them an indispensable asset for modern chlor-alkali facilities aiming to optimize their production capabilities.

Exceptional Durability and Longevity

Corrosion Resistance in Harsh Environments

The chlor-alkali process is notorious for its corrosive environment, characterized by high concentrations of chlorine and caustic solutions. Platinum plated titanium mesh electrodes excel in this challenging setting due to their remarkable corrosion resistance. The titanium substrate provides a sturdy foundation, while the platinum coating acts as a protective barrier against chemical attack. This synergistic combination results in electrodes that can withstand the aggressive conditions of chlor-alkali cells for extended periods without significant degradation.

The superior corrosion resistance of these electrodes translates to reduced maintenance requirements and fewer production interruptions. Plant operators can rely on the longevity of platinum plated titanium mesh electrodes, minimizing the need for frequent replacements and associated downtime. This durability not only contributes to cost savings but also ensures consistent production output, a crucial factor in meeting the demands of various industries that depend on chlor-alkali products.

Mechanical Strength and Structural Integrity

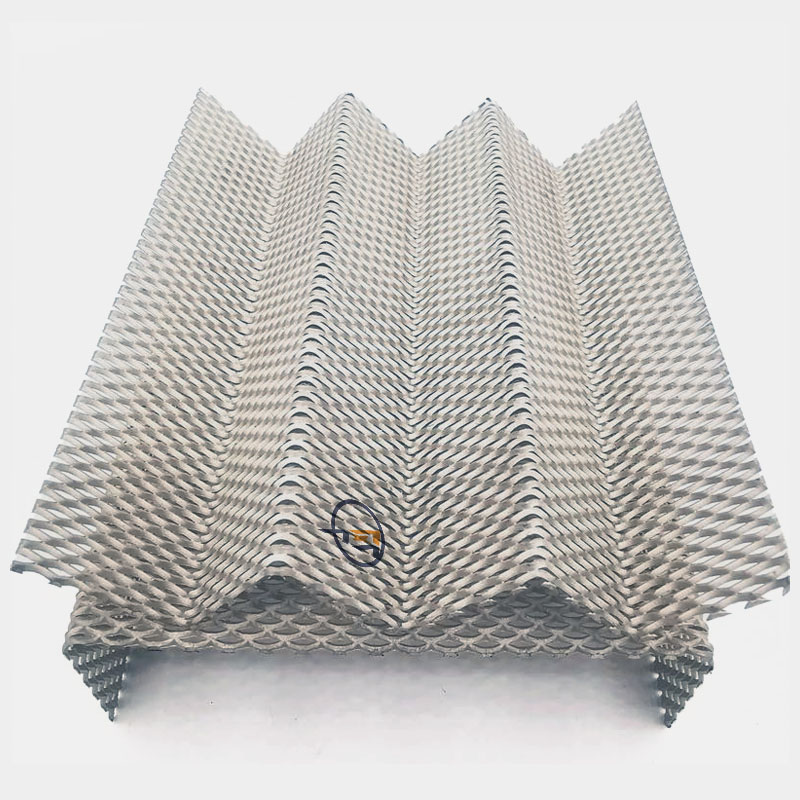

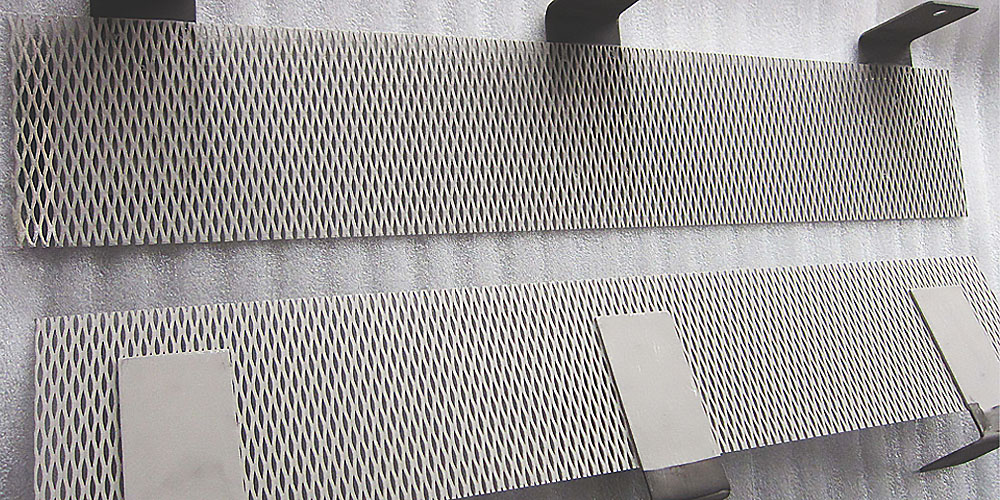

The mesh structure of platinum plated titanium electrodes offers an ideal balance between surface area and mechanical strength. The titanium base provides excellent structural support, allowing the electrode to maintain its shape and integrity even under the stresses of continuous operation. This robustness is particularly valuable in large-scale chlor-alkali plants where electrodes are subjected to significant mechanical and thermal stresses.

The mesh design also allows for optimal gas release during electrolysis, preventing the accumulation of bubbles that could potentially interfere with the electrochemical process. This feature contributes to the overall stability and efficiency of the chlor-alkali cell, ensuring consistent performance over time. The combination of mechanical strength and efficient gas management makes platinum plated titanium mesh electrodes a reliable choice for long-term industrial applications.

Resistance to Dimensional Changes

One of the challenges in chlor-alkali production is maintaining the dimensional stability of electrodes over time. Platinum plated titanium mesh electrodes exhibit excellent resistance to dimensional changes, even after prolonged exposure to harsh operating conditions. This stability is crucial for maintaining optimal inter-electrode spacing and ensuring uniform current distribution across the cell.

The dimensional stability of these electrodes contributes to the overall efficiency and reliability of the chlor-alkali process. It allows for more precise control of operating parameters and helps maintain consistent product quality. Furthermore, the resistance to warping or deformation reduces the risk of short circuits or uneven current distribution, which could otherwise lead to safety hazards or reduced production efficiency.

Enhanced Electrical Conductivity and Energy Efficiency

Optimized Current Distribution

The unique structure of platinum plated titanium mesh electrodes facilitates optimal current distribution throughout the chlor-alkali cell. The mesh design provides a large surface area for electrochemical reactions while maintaining low electrical resistance. This combination allows for efficient current flow and uniform distribution across the electrode surface, leading to improved overall cell performance.

The enhanced current distribution contributes to several benefits in chlor-alkali production. It promotes more uniform electrolysis, resulting in consistent product quality and reduced formation of unwanted by-products. Additionally, the optimized current flow helps minimize localized heating and potential hot spots, which can be detrimental to electrode longevity and cell efficiency.

Reduced Energy Consumption

Energy efficiency is a critical factor in the economics of chlor-alkali production. Platinum plated titanium mesh electrodes contribute significantly to reducing energy consumption in these processes. The combination of high electrical conductivity and catalytic activity allows for lower operating voltages compared to traditional electrode materials.

The reduced energy requirements translate directly into cost savings for chlor-alkali producers. Lower power consumption not only decreases operational expenses but also aligns with sustainability goals by reducing the carbon footprint associated with electricity generation. As industries worldwide focus on energy-efficient processes, the adoption of platinum plated titanium mesh electrodes represents a strategic move towards more sustainable chlor-alkali production.

Minimized Voltage Drop

Voltage drop across electrodes is a significant concern in chlor-alkali cells, as it directly impacts energy efficiency and production costs. Platinum plated titanium mesh electrodes excel in minimizing voltage drop due to their superior electrical properties. The high conductivity of both titanium and platinum, combined with the optimized mesh structure, results in lower resistive losses within the electrode.

The reduced voltage drop contributes to improved overall cell efficiency and allows for operation at lower total cell voltages. This not only saves energy but also reduces the thermal stress on cell components, potentially extending the lifespan of other materials within the chlor-alkali system. The ability to operate at lower voltages while maintaining high production rates makes platinum plated titanium mesh electrodes an attractive option for modernizing existing plants or designing new, high-efficiency facilities.

Superior Catalytic Activity and Process Efficiency

Enhanced Reaction Kinetics

The platinum coating on titanium mesh electrodes provides exceptional catalytic properties, significantly enhancing the reaction kinetics in chlor-alkali processes. Platinum is renowned for its ability to facilitate electron transfer and promote the desired electrochemical reactions. In the context of chlor-alkali production, this translates to faster chlorine evolution at the anode and more efficient hydrogen production at the cathode.

The improved reaction kinetics lead to several benefits in chlor-alkali cells. Higher reaction rates allow for increased production capacity without the need for larger cell sizes or higher current densities. This efficiency boost can be particularly valuable for facilities looking to expand production within existing infrastructure constraints. Additionally, the enhanced kinetics contribute to more stable operation and reduced sensitivity to fluctuations in operating conditions.

Selectivity and Product Purity

Platinum plated titanium mesh electrodes demonstrate superior selectivity in chlor-alkali applications, promoting the formation of desired products while minimizing side reactions. The catalytic properties of platinum, combined with the optimized surface area of the mesh structure, create an ideal environment for selective chlorine and caustic soda production.

The high selectivity of these electrodes contributes to improved product purity, a critical factor in many chlor-alkali applications. Higher purity products often command premium prices and can open up new market opportunities for producers. Furthermore, the reduction in unwanted by-products simplifies downstream processing and purification steps, potentially leading to additional cost savings and improved overall process efficiency.

Stable Performance Over Time

One of the most significant advantages of platinum plated titanium mesh electrodes is their ability to maintain stable performance over extended periods. Unlike some electrode materials that may suffer from gradual degradation or loss of catalytic activity, these electrodes exhibit remarkable consistency in their electrochemical properties throughout their operational life.

The stable performance of platinum plated titanium mesh electrodes ensures consistent product quality and production rates over time. This reliability is crucial for chlor-alkali producers who need to meet stringent quality standards and maintain steady output to fulfill customer commitments. The long-term stability also simplifies process control and reduces the need for frequent adjustments to operating parameters, contributing to smoother and more efficient plant operation.

In summary

The adoption of platinum plated titanium mesh electrodes in chlor-alkali applications represents a significant advancement in electrode technology. Their exceptional durability, enhanced electrical conductivity, and superior catalytic activity offer a compelling trifecta of benefits that address key challenges in the industry. These electrodes not only improve process efficiency and product quality but also contribute to long-term cost savings and sustainability efforts. As the chlor-alkali sector continues to evolve, the role of platinum plated titanium mesh electrodes in shaping the future of efficient and environmentally responsible production cannot be overstated.