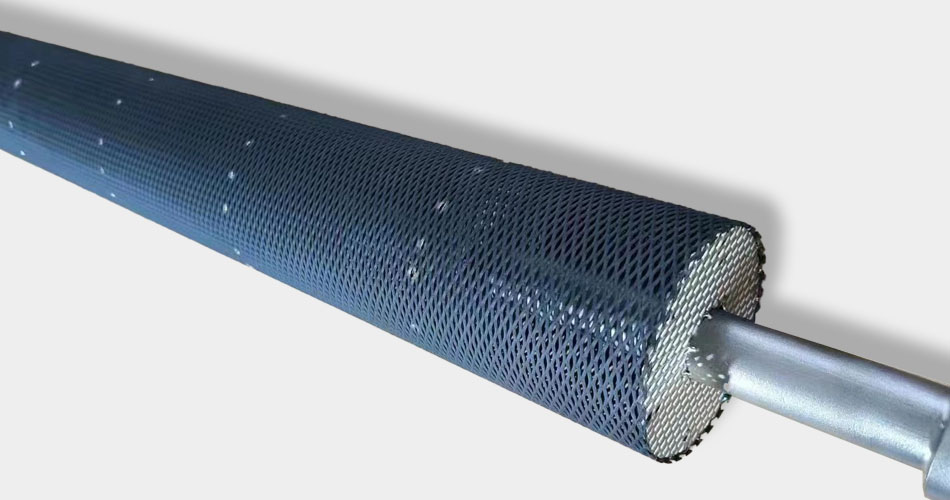

Preparation of oxygen evolution type iridium tantalum coated titanium anode

With the successful application of chlorine evolution type precious metal coated titanium anode in the chlor-alkali industry, oxygen evolution type precious metal coated titanium anode has gradually gained favor in applied electrochemistry. In the acidic oxygen evolution environment, the anode will be severely corroded by acid and strongly oxidized by oxygen evolution, and the anode will undergo loss and corrosion. Therefore, an oxygen evolution type precious metal coated titanium anode with excellent electrochemical catalytic activity and superior electrolytic lifetime has always been the goal of electrochemical workers. Iridium-based coated and ruthenium-based coated titanium anodes are currently the two most important electrode materials for precious metal coated titanium anodes. They mainly use RuO2 and IrO2 as the main active substances respectively. Currently, the preparation method of coated titanium anodes is mainly based on high-temperature thermal decomposition oxidation method. Although the iridium tantalum coated anode is not as active as the ruthenium-based coated anode in chlorine evolution, it can maintain certain stability in the oxygen evolution environment. Therefore, the iridium tantalum coated anode is the main anode in the current oxygen evolution environment. Over the years, together with our customers, we have studied and improved the precious metal components of the coating and the preparation method of the coating to continuously improve the performance of the iridium tantalum coated anode for the problems encountered in the application.

Failure mechanism of precious metal coating on titanium anode

Iridium tantalum precious metal coated titanium anode, as an anode material in a strongly acidic oxygen evolution environment, is required to have certain electrocatalytic activity and conductivity, as well as sufficient stability and corrosion resistance. Due to the actual working life of titanium anode being very long, up to several months or even years, enhanced life tests are generally adopted in the laboratory. During the enhanced electrolysis process under constant current, when the cell voltage of the coated titanium anode suddenly rises significantly, the anode coating fails at this time. The reasons for the failure of the precious metal coated titanium anode are quite complex. For different anodes and operating environments, the dominant factors of the failure mechanism will also be different. Currently, the more common failure mechanisms are coating dissolution and coating peeling. However, in the entire failure process of the anode, these two points do not exist singly, but occur simultaneously or successively, thereby leading to passivation of the substrate and accelerating the failure of the anode.