MMO Anodes Overview

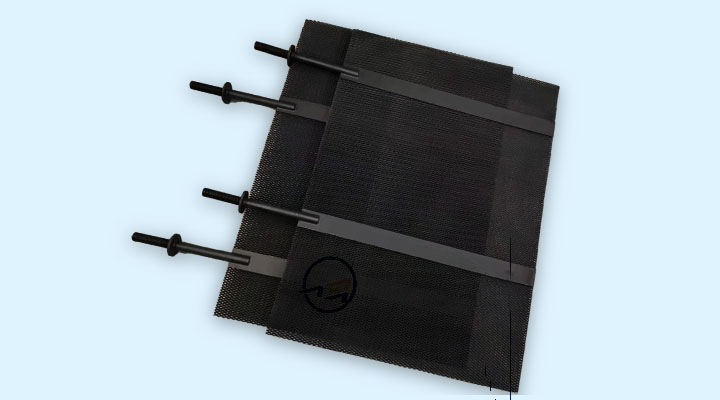

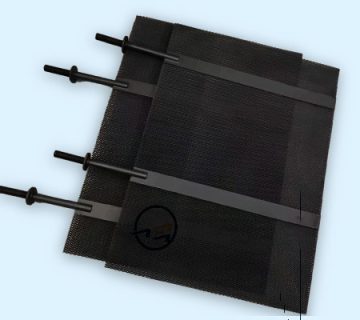

MMO anodes

Originally developed to produce chlorine from seawater electrolysis, MMO anodes have been used in cathodic protection (CP) applications since the 1980s. They have continued to gain acceptance in a wide range of applications due to significant advantages.

MMO Anode Advantages

Demonstrated reliability

Exceptionally long life

Available in numerous anode configurations

Light weight

Low cost

MMO anodes have imperceptibly low wear rates and are often referred to as Dimensionally Stable Anodes (DSA) as they do not change geometry over time. MMO anodes are quickly becoming the most popular impressed current anode gaining market share over conventional anodes such as graphite and high silicon cast iron.

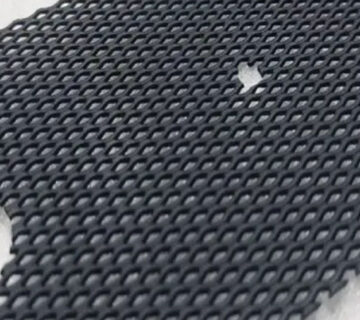

What is mixed metal oxide anodes?

There is no precise industry definition for “mixed metal oxide.” Each supplier has a unique recipe for their mixed metal oxide coating. The coating recipe consists of an electro catalytic conductive component that catalyzes the reaction to generate current flow, and bulk oxides (cheaper fill materials) that prevent corrosion of the substrate material. For cathodic protection applications two primary electrocatalysts are used:

Ruthenium Oxide (RuO2)

Ruthenium oxide, which is the cheaper of the two electrocatalysts, should only be used in chlorinated environments (sea water). The catalytic life is significantly reduced when the primary reaction is the evolution of oxygen (fresh water, soil, coke backfill and concrete environments).

Iridium Oxide (IrO2)

Most CP manufacturers use Iridium Oxide based mixed metal oxide for their cathodic protection anodes. The bulk oxides are typically a mixture of Titanium Dioxide (TiO2) and Tantalum Oxide (TaO5). Their primary purpose is to provide an oxide film over the substrate material to prevent corrosion of the substrate.

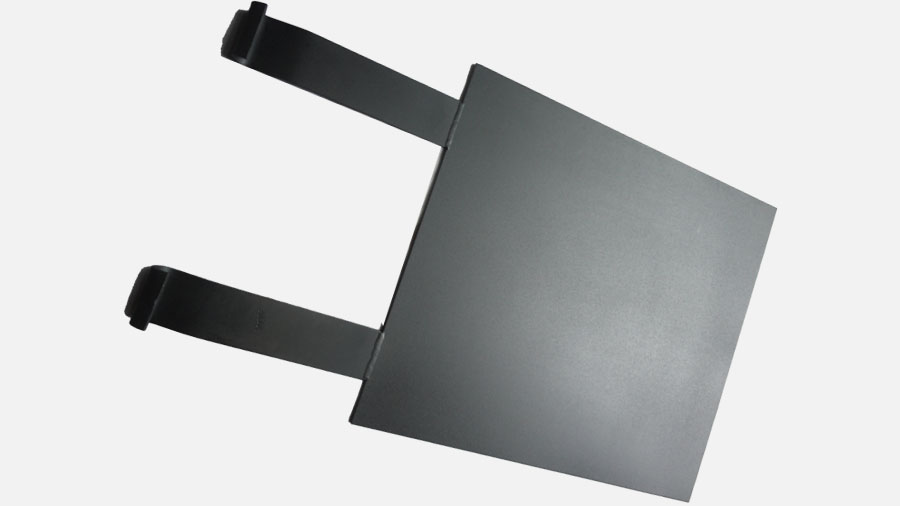

MMO Coated Titanium Anodes

Mixed metal oxide anodes are applied over a commercially pure titanium substrate. Titanium offers several key advantages as a substrate:

Titanium MMO Anode Advantages

Titanium is readily available in commercially pure form

Excellent adherence properties with proper surface preparation

Lightweight

Outstanding mechanical strength

Outstanding chemical resistance to highly acidic conditions – typical for oxygen and chlorine evolving environments common in many cathodic protection applications

Commercially pure titanium is available in a range of grades. For MMO anodes, Grades 1 and 2 are used for MMO anodes. Grade 1 titanium is slightly more malleable than Grade 2 titanium but is also less commonly used in industry. The specifications for Grade 1 and Grade 2 are very similar and overlap so that often the same material meets the requirements of both Grade 1 and Grade 2 and can be dual certified. There is no “better” between Grade 1 and Grade 2 – they can be used interchangeably with no impact on performance.