To maintain and replace MMO (Mixed Metal Oxide) titanium anodes properly is key to preserving their long-term stability, sustaining high electrocatalytic performance, and avoiding unexpected downtime in electrochemical systems (such as wastewater treatment, chlor-alkali production, or water disinfection).

Routine Maintenance: Extend Anode Service Life

Regular maintenance addresses minor issues early, prevents premature coating degradation, and keeps the anode working at its optimal state. Focus on three core tasks:

1.Targeted Cleaning to Remove Fouling

Fouling (e.g., inorganic scale, organic deposits, or biofilm) accumulates on the MMO coating over time, blocking active catalytic sites and reducing efficiency. Clean based on the type of fouling:

Inorganic scale (e.g., CaCO₃, Mg(OH)₂): Common in high-hardness water systems (e.g., industrial wastewater with high TDS). Soak the anode in a 5–10% citric acid or dilute nitric acid solution for 2–4 hours—this dissolves scale without damaging the MMO coating. After soaking, rinse thoroughly with deionized water to remove residual acid.

Organic deposits (e.g., oil, biofilm): Typical in wastewater with high organic content. Use a 2–5% sodium hydroxide (NaOH) solution heated to 40–60°C; soak the anode for 1–2 hours to break down organics, then rinse with clean water.

Physical pre-cleaning: For loose, surface-level fouling, use a soft nylon brush (avoid metal or abrasive brushes) or low-pressure water (≤5 MPa) to wipe/rinse first—this reduces the need for harsh chemicals.

Frequency: Clean monthly in high-fouling environments (e.g., refractory organic wastewater treatment) or every 3–4 months in cleaner systems (e.g., swimming pool disinfection).

2.Real-Time Monitoring of Operational Parameters

Abnormal parameters often signal hidden issues (e.g., coating wear or poor connections). Track these key metrics:

Current density: Stay within the anode’s rated range (usually 100–1000 A/m²). Exceeding the maximum current density generates excessive heat, accelerating MMO coating dissolution and titanium substrate corrosion.

Cell voltage: Record the baseline voltage when the anode is new. A sudden (≥10%) or gradual (≥20% over 3 months) voltage increase indicates problems—this could mean fouling, coating degradation, or loose electrical connections.

Electrolyte conditions: Monitor pH (ideal range: 1–14 for most MMO coatings), chloride concentration, and impurity levels (e.g., Fe³⁺, S²⁻). Acidic conditions (pH <2) may corrode the titanium substrate if the coating is damaged; sulfides (S²⁻) can “poison” the MMO coating, disabling its catalytic activity.

Temperature: Keep the electrolyte temperature below 60°C. High temperatures (above 60°C) speed up coating oxidation and reduce the anode’s service life.

3.Inspection of Electrical Connections

Poor electrical contact causes uneven current distribution, creating “hotspots” on the anode surface that degrade the MMO coating.

Check bus bars, bolts, and cables for corrosion, looseness, or overheating (e.g., discolored insulation). Corroded parts can be cleaned with a wire brush; loose bolts should be tightened (avoid over-tightening to prevent thread damage).

Apply anti-corrosion grease (e.g., graphite-based grease) to titanium or copper connections after cleaning—this prevents future corrosion and ensures stable current flow.

Replacement: Know When and How to Swap Anodes

MMO titanium anodes typically last 3–7 years, but harsh conditions (e.g., high current density, acidic electrolytes) may shorten this period. Replace anodes when these signs appear, and follow the correct replacement process:

1.Signs That Replacement Is Necessary

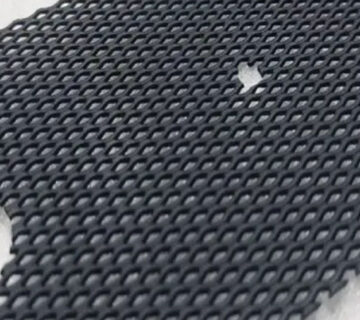

Coating damage: Visual cues include peeling, cracking, or discoloration of the MMO layer (e.g., from its original metallic gray to dull black or white). If the titanium substrate is exposed (shiny silver or rust-colored), replace immediately—exposed titanium corrodes quickly in electrolytes.

Persistent performance drop: Even after cleaning, if pollutant removal efficiency (e.g., COD reduction in wastewater) drops by ≥20%, or chlorine production (in disinfection systems) falls significantly, the coating’s catalytic activity is irreversibly reduced.

Uncontrollable high voltage: If cell voltage remains ≥20% above the baseline (after cleaning and checking connections), the coating is degraded and can no longer reduce reaction overpotential.

Physical damage: Bending, warping, or cracks in the titanium substrate (from mechanical impact or thermal shock) disrupt current distribution and require replacement.

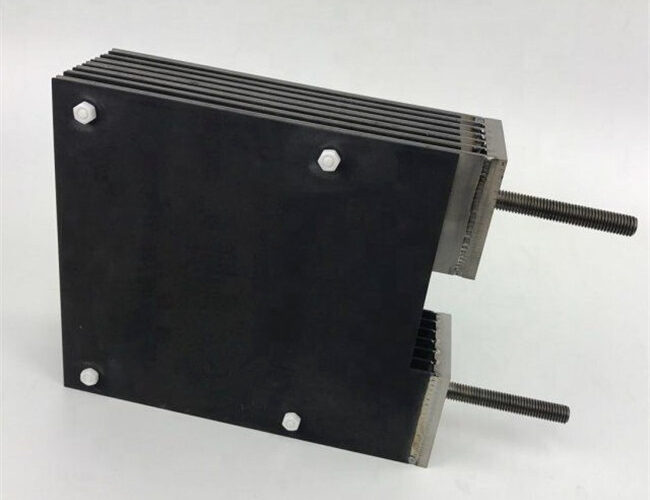

2.Step-by-Step Replacement Process

Preparations: First, shut down the power supply to the electrochemical system and drain the electrolyte (dispose of it according to environmental regulations). Wait for the cell to cool to ≤40°C to avoid burns; wear acid-resistant gloves, goggles, and protective clothing—electrolytes may be corrosive.

Remove old anodes: Loosen and disconnect electrical connections (bus bars, bolts) using titanium or plastic tools (metal tools may spark or scratch components). Carefully extract old anodes, avoiding contact with cathodes or cell walls to prevent damage. Inspect the cell interior for fouling or corrosion—clean or repair the cell if needed (e.g., patch small cracks in the tank).

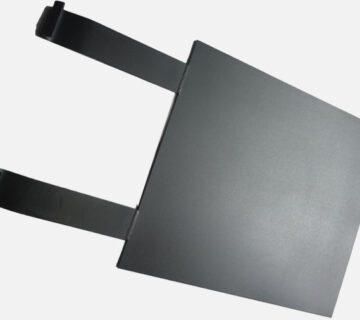

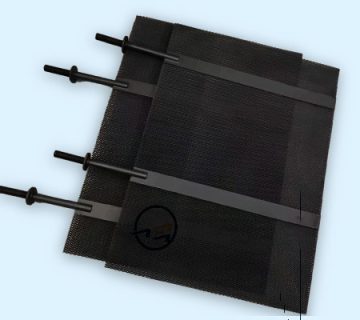

Install new anodes: Check new anodes for intact MMO coatings (no scratches, peeling, or contamination) and ensure their dimensions match the cell (e.g., length, diameter). Install anodes parallel to cathodes with uniform spacing (usually 5–20 mm)—use plastic spacers if needed to prevent short circuits. Tighten electrical connections securely, then apply anti-corrosion grease to contacts.

Post-installation testing: Refill the cell with fresh electrolyte and run a trial operation at 50% of the rated current density for 1–2 hours. Monitor cell voltage, current distribution, and for leaks. If voltage is stable and no leaks are found, gradually increase to the rated current density and verify performance (e.g., test COD levels in wastewater or residual chlorine in disinfection systems) to ensure it meets standards.

Who we are

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

Production

1. Substrate treatment: it needs to be treated by roughing, cleaning and removing oil, which can increase the compactness of catalytic.

2. Brushing coating:After substrate treatment, it will be proceeded brush coated. The main coated content is platinum group metal, which is a kind of mixed solution.Then, heat treatment will be going on after drying.The whole procedure need to be repeated many times. This method is better to form thin oxide catalytic that is lamellar adhere to substrate surface.

Why Choose Us?

Unrivaled Product Quality

Crafted from premium titanium with precision and strict quality control, our anodes use advanced coating methods like thermal decomposition. Catalytic layers such as RuO₂-IrO₂ or SnO₂-Sb₂O₃ boost corrosion resistance, electrochemical activity, and lifespan.

Exceptional Performance

With low overpotential, our anodes cut energy use by up to 30% in electrochemical oxidation. High current efficiency enables fast degradation of organic pollutants, heavy metals, and PFAS across various wastewater types.

Customized Solutions

We customize anode coating, thickness, and structure. Our experts analyze your project to ensure cost-effective, optimized performance.

Extensive Industry Experience

Years of work in textiles, pharmaceuticals, and mining give us deep expertise for proactive problem-solving.

Comprehensive Technical Support

Our support covers installation, maintenance, troubleshooting, and staff training.

Sustainable and Environmentally Friendly

Designed to reduce energy use and heavy metal release, our anodes prioritize sustainability, with ongoing R&D for improvements.

Competitive Pricing

Despite top quality, optimized processes and supply chains make our anodes affordable.

Choose us for superior quality, performance, and service. Contact us to achieve your wastewater treatment goals.

Quality assurance and after-sales service

1. We promise that our substrate is high quality,acceleratd life test.The coating solution is configured according to the certain proportion.

2.With the high technology and equipment,All of our tecnical personnel have abundant experience,and our workers are very skilled.During the production of the Titanium anode, each process must carry on the strict examination,Such as the detection of surface rougghness,The quality of coating solution,coating evenness and so on.

3.We have our own production,sales and after-service department.We are usually dedicated to provide customers with high quality and reasonable price product.Most importantly ,we can provide the efficient service.

4.Each procedure will be carefully detected in the technical staff to compelete.accomplish the order in time and delivery on time.

5.During our cooperation,if you have any problem ,you can contact us at anytime,we will do our umost to help you.