Titanium anode have become an essential component in the process of electrolytic copper foil production, offering several significant advantages that contribute to the quality and efficiency of this manufacturing process.

The use of titanium anode in electrolytic copper foil production is primarily driven by their excellent electrochemical properties.

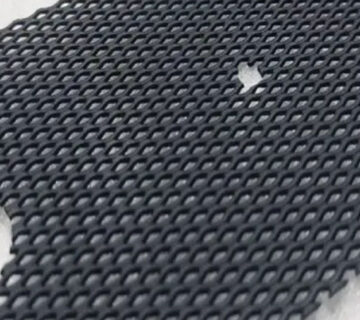

Titanium provides a stable and inert surface, which is crucial for maintaining consistent electrochemical reactions during the copper deposition process. This stability helps to ensure the uniformity and quality of the resulting copper foil.

One of the key benefits of titanium anode is their high catalytic activity. This allows for efficient electron transfer, which in turn leads to faster copper plating and higher production rates. For instance, in a typical electrolytic copper foil production line, the use of titanium anode can significantly reduce the processing time and increase the output of high-quality copper foil.

Furthermore, titanium anode exhibit superior corrosion resistance. They can withstand the harsh electrolytic environment, which often contains aggressive chemicals and high current densities, without undergoing significant degradation. This durability not only reduces the frequency of anode replacement but also lowers maintenance costs and production downtime.

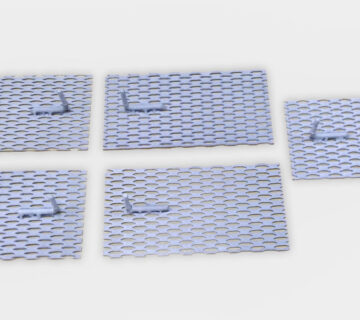

The design and surface modification of titanium anodes can also be customized to optimize their performance in specific electrolytic copper foil production setups. Different coatings or surface treatments can be applied to enhance their catalytic activity, improve current distribution, and further increase the quality and properties of the produced copper foil.

In conclusion, titanium anode play a vital role in the electrolytic copper foil production industry.

Their unique combination of electrochemical properties, catalytic activity, corrosion resistance, and customizability makes them an indispensable tool for achieving high-quality copper foil with improved efficiency and reduced costs.

As the demand for high-performance copper foil continues to grow, the importance of advanced titanium anode is likely to increase even further, driving innovation and development in this field.

Who we are?

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

Production

Brush coating.

Specific operation as follows:

Firstly,making the coating solution according to the type and the area of the platinum electrode; secondly ,put the solution on the surface evenly, then put them into the drying furance for drying; thirdly,we need to oxidate in the high temperature oxidation furance;Lastly, dry it to room temperature. Then,repeat these steps until you run out the configuration solution.

Certification

Qixin is ISO 9001:2015 certified and own more than 10 patents. All its processes and procedures are documented and controlled in accordance with these standard. Qixin has strict product quality control procedure, from raw material to finished product, all the process is tested qualified to assure high quality product.

With technical engineers experienced for more than 18 years of constant research and production for titanium electrode and its application in various industries, Qixin can offer a very high level of technical support and products, which are among its most remarkable characteristics.

FAQ

1. How to ensure the product quality?

All products make 100% inspection before shipment also we can provide the MTC Material Test Certification.

2. Can you print our Logo on the products?

Sure, and we welcome the customerized products.

3.What about the payment terms?.

T/T, L/C, Paypal, Western Union, Escrew and MoneyGram etc are all accepted.

4.What is the necessary information for an inquiry?

Product name, specification, material grade and quantity.

5.Can we get a free sample before cargo production?

Sure.