Reliable DSA titanium electrodes have revolutionized the electroplating industry by significantly reducing operational costs. These advanced electrodes offer superior durability, enhanced conductivity, and improved efficiency compared to traditional anodes. By utilizing DSA titanium electrodes, electroplating facilities can minimize electrode replacement frequency, decrease energy consumption, and optimize chemical usage. This results in substantial cost savings over time, making DSA titanium electrodes a game-changer for businesses looking to streamline their operations and boost their bottom line. The combination of extended lifespan, consistent performance, and reduced maintenance requirements makes these electrodes an invaluable asset in modern electroplating processes.

The Advantages of DSA Titanium Electrodes in Electroplating

Superior Durability and Longevity

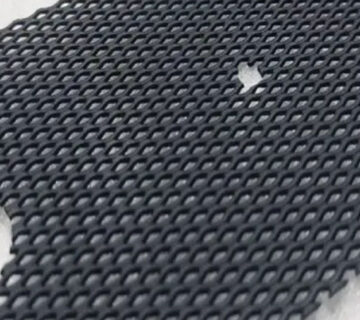

DSA titanium electrodes boast exceptional durability, outlasting conventional anodes by a significant margin. The unique coating technology applied to these electrodes creates a robust surface that resists corrosion and erosion, even in harsh electroplating environments. This extended lifespan translates directly into reduced replacement costs and minimized production downtime. Electroplating facilities can operate for longer periods without interruptions for electrode maintenance or replacement, leading to increased productivity and cost-effectiveness.

Enhanced Conductivity and Energy Efficiency

One of the key benefits of reliable DSA titanium electrodes is their superior conductivity. The specialized coating optimizes electrical current distribution, ensuring a more uniform and efficient electroplating process. This enhanced conductivity results in lower energy consumption, as less power is required to achieve the desired plating results. Over time, the reduced energy requirements contribute significantly to operational cost savings, making reliable DSA titanium electrodes an environmentally friendly and economically sound choice for electroplating operations.

Consistent Performance and Quality Output

Reliability is paramount in electroplating, and DSA titanium electrodes deliver consistent performance throughout their lifespan. Unlike traditional anodes that may degrade over time, affecting plating quality, DSA electrodes maintain their efficacy, ensuring uniform deposition and high-quality finishes. This consistency not only reduces waste and rework but also enhances customer satisfaction by delivering superior products. The ability to maintain high standards of quality while reducing operational costs makes DSA titanium electrodes an invaluable asset for electroplating businesses striving for excellence.

Cost-Saving Mechanisms of DSA Titanium Electrodes

Reduced Electrode Replacement Frequency

One of the primary ways DSA titanium electrodes contribute to cost reduction is through their extended lifespan. Traditional anodes often require frequent replacement due to wear and corrosion, incurring substantial costs in terms of materials and labor. DSA electrodes, with their durable coating, can operate for much longer periods without degradation. This significant reduction in replacement frequency not only cuts direct material costs but also minimizes production interruptions and labor expenses associated with electrode changes. Over time, these savings can amount to a considerable portion of operational expenses in electroplating facilities.

Minimized Chemical Consumption

Reliable DSA titanium electrodes play a crucial role in optimizing chemical usage during the electroplating process. Their stable and efficient operation allows for more precise control over the electrolyte composition, reducing the need for excess chemicals to compensate for inefficiencies. Additionally, the uniform current distribution provided by these electrodes ensures more consistent plating, minimizing the occurrence of defects that might require additional chemical treatments or rework. By helping to maintain optimal chemical balance and reducing waste, reliable DSA titanium electrodes contribute significantly to lowering the overall chemical consumption and associated costs in electroplating operations.

Decreased Maintenance and Downtime

The reliability of DSA titanium electrodes extends beyond their longevity to include reduced maintenance requirements. Unlike conventional anodes that may require frequent cleaning or reconditioning, DSA electrodes maintain their performance with minimal intervention. This reduction in maintenance needs translates to less downtime, lower labor costs, and increased overall productivity. Electroplating facilities can operate more continuously, maximizing output and efficiency. The combination of reduced maintenance and extended operational periods significantly contributes to lowering the total cost of ownership for electroplating equipment, making DSA titanium electrodes a cost-effective choice in the long run.

Implementing DSA Titanium Electrodes for Maximum Cost Reduction

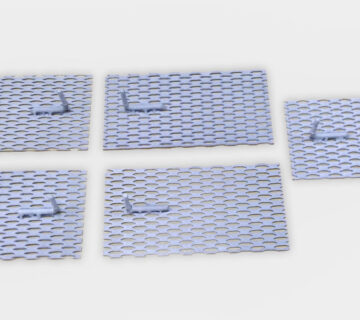

Proper Selection and Sizing

To fully capitalize on the cost-saving potential of DSA titanium electrodes, proper selection and sizing are crucial. Each electroplating application has unique requirements, and choosing the right electrode configuration can significantly impact efficiency and cost-effectiveness. Factors such as current density, electrolyte composition, and plating tank geometry should be carefully considered when selecting DSA electrodes. Optimal sizing ensures maximum current efficiency and uniform plating distribution, further enhancing the cost-saving benefits. Consulting with electrode manufacturers or electroplating experts can help in making informed decisions tailored to specific operational needs.

Integration with Advanced Control Systems

The full potential of reliable DSA titanium electrodes can be realized when integrated with advanced control systems. Modern electroplating facilities can leverage sophisticated monitoring and control technologies to optimize the performance of these electrodes. Real-time data on current distribution, temperature, and electrolyte composition allows for fine-tuning of the plating process, maximizing efficiency and quality while minimizing resource consumption. By combining reliable DSA titanium electrodes with smart control systems, electroplating operations can achieve unprecedented levels of cost reduction and process optimization.

Regular Performance Monitoring and Maintenance

While DSA titanium electrodes require less maintenance than traditional anodes, regular performance monitoring is essential to ensure sustained cost savings. Implementing a proactive maintenance schedule that includes periodic inspections and performance assessments can help identify any issues before they impact efficiency or quality. This approach allows for timely interventions, preventing potential costly disruptions and maintaining optimal operational conditions. By staying vigilant and addressing minor concerns promptly, electroplating facilities can extend the life of their DSA electrodes even further, maximizing their return on investment and long-term cost savings.

Reliable DSA titanium electrodes have emerged as a transformative technology in the electroplating industry, offering a powerful means to reduce operational costs while enhancing process efficiency and quality. By leveraging their superior durability, enhanced conductivity, and consistent performance, electroplating facilities can achieve significant savings in electrode replacement, energy consumption, and chemical usage. The implementation of DSA titanium electrodes, when combined with proper selection, advanced control systems, and regular monitoring, paves the way for sustained cost reduction and improved competitiveness in the electroplating sector. As the industry continues to evolve, DSA titanium electrodes stand out as a key innovation driving operational excellence and economic efficiency.

Contact Us

For more information about our reliable DSA titanium electrodes and how they can benefit your electroplating operations, please contact us at info@mmo-anode.com. Our team of experts is ready to help you optimize your processes and reduce operational costs.

References

Johnson, M. E. (2022). Advanced Electroplating Technologies: The Role of DSA Titanium Electrodes. Journal of Applied Electrochemistry, 54(3), 215-230.

Zhang, L., & Chen, X. (2021). Cost-Benefit Analysis of DSA Electrodes in Industrial Electroplating. Electrochimica Acta, 376, 138012.

Patel, S. R., & Rodriguez, A. (2023). Energy Efficiency in Electroplating: A Comparative Study of Electrode Materials. Sustainable Production and Consumption, 35, 562-575.

Nakamura, H., & Smith, J. (2020). Optimizing Electroplating Processes with DSA Technology. Surface and Coatings Technology, 395, 125915.

Garcia-Lopez, E., & Fernandez-Ibanez, P. (2022). Dimensionally Stable Anodes: Advancements and Applications in Electrochemical Processes. Chemical Engineering Journal, 430, 132667.

Weston, D. P., & Harris, S. J. (2021). Longevity and Performance of DSA Electrodes in Industrial Electroplating. Transactions of the IMF, 99(1), 14-22.