Titanium anode have emerged as a vital component in sodium hypochlorite generators, playing a crucial role in the efficient and reliable production of this important disinfectant.

The unique properties of titanium make it an ideal choice for anodes in these generators. Titanium is highly resistant to corrosion, which is essential when exposed to the harsh chemical environment within the generator. This resistance ensures the longevity and consistent performance of the anode.

The electrochemical processes in a sodium hypochlorite generator rely heavily on the functionality of the titanium anode. It facilitates the oxidation and reduction reactions that lead to the formation of sodium hypochlorite. For instance, at the anode, chloride ions are oxidized to form chlorine gas, which subsequently reacts with water to produce hypochlorous acid and hypochlorite ions – the key disinfecting components.

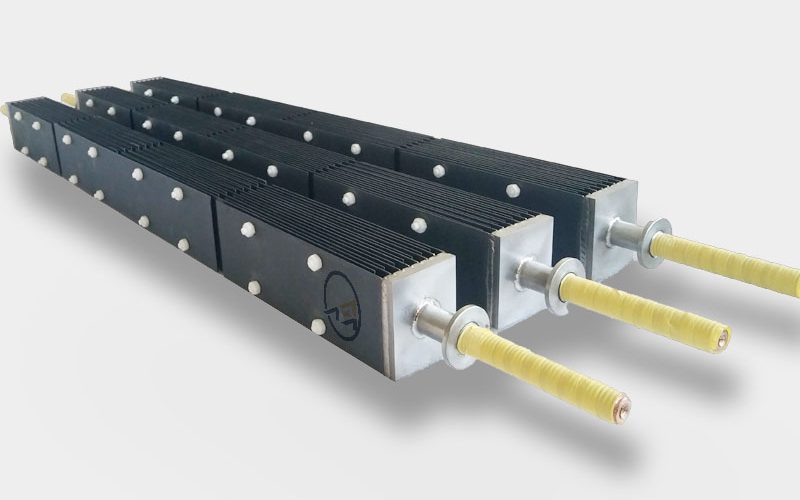

The design and surface characteristics of the titanium anode are engineered to maximize its efficiency. A larger surface area allows for greater interaction with the electrolyte, enhancing the rate of electrochemical reactions and increasing the output of sodium hypochlorite.

In practical applications, such as in water treatment plants, the use of titanium anodes in sodium hypochlorite generators ensures a continuous supply of a potent disinfectant. This helps maintain the quality and safety of the water being treated.

Furthermore, the low maintenance requirements of titanium anodes contribute to the overall cost-effectiveness of the sodium hypochlorite generation process. Their durability and reliability make them a preferred choice in various industries where disinfection is of paramount importance.

Titanium anode are indispensable in sodium hypochlorite generators, providing a combination of performance, longevity, and ease of maintenance that is crucial for effective and sustainable disinfection processes.

The titanium anode has the following important roles in the sodium hypochlorite generator

- Promoting electrolytic reaction: The titanium anode provides a site for the electrolytic reaction, causing chloride ions (Cl–) to lose electrons at the anode and undergo oxidation reaction, providing necessary conditions for the chemical process of generating sodium hypochlorite.

For example, in industrial wastewater treatment, the titanium anode can efficiently drive the electrolytic process and convert chloride ions in the wastewater into sodium hypochlorite with disinfection effects. - Enhancing current efficiency: Its good electrical conductivity helps improve the transmission efficiency of the current, thereby promoting the generation of sodium hypochlorite more effectively.

Taking large-scale water treatment plants as an example, efficient current efficiency means being able to produce a sufficient amount of sodium hypochlorite in a shorter time to meet the disinfection needs of a large amount of water. - Corrosion resistance: It can resist the erosion of chemical substances in the electrolytic environment, maintain long-term stable working performance, and reduce the cost of equipment maintenance and replacement.

Under harsh electrolytic conditions, such as high-concentration brine and complex ionic environments, the titanium anode can still operate stably to ensure the continuous operation of the sodium hypochlorite generator. - Improving reaction selectivity: It helps control the selectivity of the reaction, making the reaction generating sodium hypochlorite dominant, reducing the occurrence of side reactions, and improving the purity and efficiency of the product.

For example, in the pool water disinfection system, the titanium anode can precisely promote the electrolytic reaction in the direction of generating sodium hypochlorite, an effective disinfection component.