Titanium anodes, particularly those coated with ruthenium-iridium (Ru-Ir) oxides, are critical components in seawater electro chlorination (SWEC) systems, which are used to generate hypochlorous acid (HOCl) for biofouling control, disinfection, and water treatment in marine environments.

What is Seawater Electro Chlorination (SWEC)?

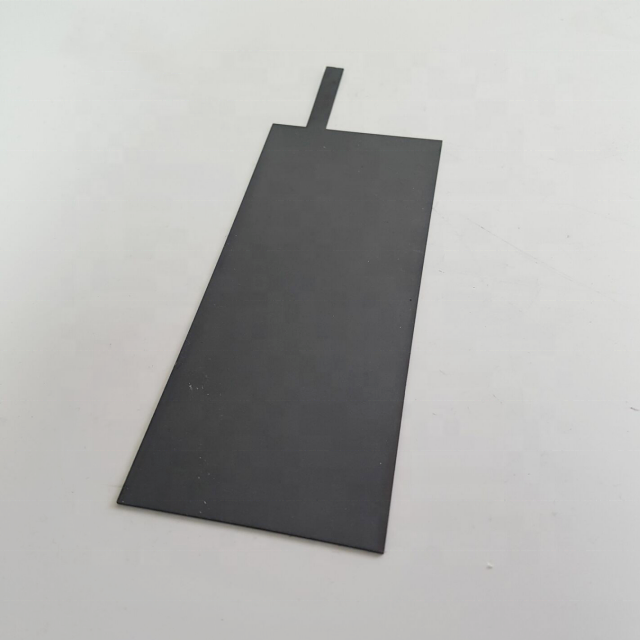

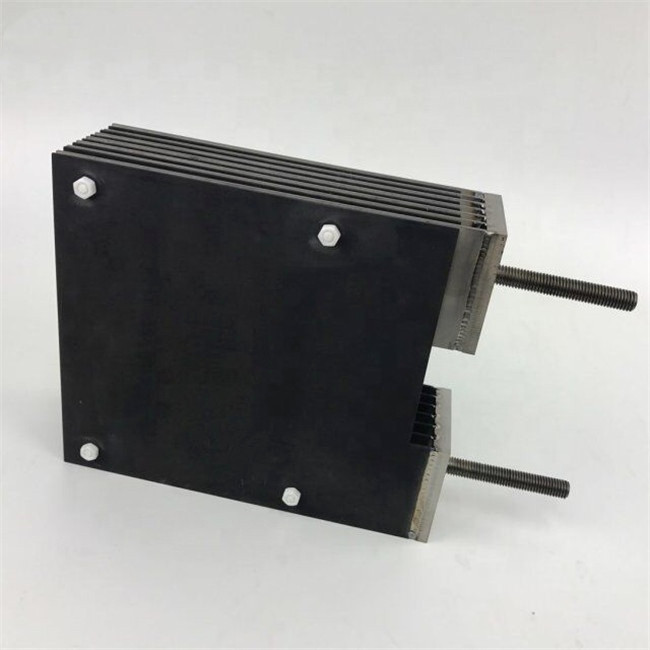

Feature of ru-ir titanium anode

1. Exceptional Corrosion Resistance

Titanium substrate: Naturally immune to seawater corrosion, even in high-salinity, turbulent, or biofouled environments.

Ru-Ir oxide coating: Forms a stable, non-soluble passive layer that resists degradation from chlorine, oxygen, and other reactive species generated during electrolysis. This extends anode lifespan to 10–15+ years (vs. shorter lifespans for uncoated or other metal anodes like platinized titanium).

2. High Efficiency for Chlorine Evolution

The Ru-Ir coating lowers the overpotential required for chlorine gas evolution, reducing energy consumption (typically 10–20% less power than alternative anodes like PbO₂ or graphite).

Maintains consistent current density (up to 1,000 A/m²) and chlorine production rates over time, even in fluctuating seawater conditions (e.g., pH, temperature, salinity).

3. Dimensional Stability

Titanium anodes do not erode or warp during electrolysis, ensuring stable electrode spacing and preventing short circuits in electrolytic cells. This is critical for maintaining uniform disinfection and avoiding system downtime.

4. Environmental and Operational Benefits

No heavy metal leaching: Unlike anodes with toxic coatings (e.g., some older mercury or cadmium-based systems), Ru-Ir coated titanium is environmentally safe and complies with strict marine discharge regulations (e.g., IMO Ballast Water Management Convention).

Low maintenance: Modular designs allow for easy replacement or recoating of the anode layer when deactivated, recycling the titanium substrate and reducing waste.

Applications of Titanium Anodes in SWEC

1. Marine Biofouling Control

Ships and offshore platforms: Prevent biofouling on hulls and ballast water systems to reduce drag, fuel consumption, and the spread of invasive species (e.g., via ballast water treatment).

Example: Cruise ships use SWEC systems with Ru-Ir anodes to treat ballast water, achieving >99% reduction in viable organisms as required by IMO D-2 standards.

2. Power Plants and Desalination Facilities

Protect seawater intake pipes and cooling systems from biofouling, which can restrict flow and increase maintenance costs.

Case study: A coastal power plant using Ru-Ir anodes reduced biofouling-related pipe blockages by 85%, cutting annual maintenance costs by $500,000.

3. Aquaculture and Fish Farms

Disinfect recirculating aquaculture systems (RAS) to control pathogens (e.g., bacteria, viruses) and reduce reliance on chemical disinfectants.

Benefit: In shrimp farms, SWEC with titanium anodes has been shown to reduce mortality rates by 30–40% while maintaining water quality.

Why Choose Ruthenium-Iridium Coated Titanium Over Alternatives?

Company profile

Qixin titanium Co.Ltd, is a leading manufacturer specializing in coated titanium anode. With an extensive historyand a wealth of expertise, we have been dedicated to providing high-quality products and solutions to variousindustries for many years.Our company was established 2006, and since then, we have accumulated 18 years of valuable manufacturingexperience. This experience has enabled us to master the art and science of producing top-notch coated titaniumanodes that meet the most stringent quality standards.We take pride in our state-of-the -art manufacturing facilities and a team of highly skilled professionals. Ourengineers and technicians are experts in the field, constantly researching and innovating to improve our productsand processes.

production

1. Substrate treatment: it needs to be treated by roughing, cleaning and removing oil, which can increase the compactness of catalytic.

2. Brushing coating:After substrate treatment, it will be proceeded brush coated. The main coated content is platinum group metal, which is a kind of mixed solution.Then, heat treatment will be going on after drying.The whole procedure need to be repeated many times. This method is better to form thin oxide catalytic that is lamellar adhere to substrate surface.

Package and shipping

(The picture is for your reference) Customized Package Is Available.

Step1: Wrapped by water proof paper

Step2: Bubble papaer

Step3: Plywood case outside to avoid any damage during the shipment.

Or packed as customer’s requirement.

Shipping :by air,by sea,Ems,Fedex or Dhl.

Delivery:15 working days after payment.

FAQ

1. How to ensure the product quality?

All products make 100% inspection before shipment also we can provide the MTC Material Test Certification.

2. Can you print our Logo on the products?

Sure, and we welcome the customerized products.

3.What about the payment terms?.

T/T, L/C, Paypal, Western Union, Escrew and MoneyGram etc are all accepted.

4.What is the necessary information for an inquiry?

Product name, specification, material grade and quantity.

5.Can we get a free sample before cargo production?

Sure.