Ruthenium-Iridium-Titanium anode (often abbreviated as Ru-Ir-Ti) is a kind of material commonly used in the field of electrochemistry. It has excellent electrocatalytic activity especially in reactions such as electrocatalytic oxidation and electrolytic reduction. This anode is mainly composed of ruthenium (Ru), iridium (Ir) and titanium (Ti). Among them, ruthenium and iridium provide electrocatalytic activity, while titanium provides strength and corrosion resistance.

The electrolysis principle of ruthenium-iridium-titanium anodes involves electrochemical reactions and is usually applied in electrochemical cells or electrolytic tanks, where the anode is the electrode where oxidation reactions occur. The following are the main electrochemical reactions of ruthenium-iridium-titanium anodes during the electrolysis process:

- Oxidation reaction: Typically, on the anode, the oxidation reaction of water takes place as follows:

4OH⁻ → O₂ + 2H₂O + 4e⁻

This is a classic water oxidation reaction, in which hydroxide ions (OH⁻) are oxidized at the anode to generate oxygen (O₂) and water (H₂O). - Anode reaction: The ruthenium-iridium alloy on the titanium substrate provides electrical conductivity and corrosion resistance, enabling the oxidation reaction to be carried out effectively. Ruthenium and iridium offer a high degree of corrosion resistance because these two metals are quite stable in many chemical environments.

- Current transfer: During the electrolysis process, the electric current passes through the ruthenium-iridium-titanium anode and delivers electrons to water molecules, facilitating the occurrence of the oxidation reaction of water.

The key role of the ruthenium-iridium-titanium anode in these reactions is to provide a stable and conductive surface while maintaining resistance to corrosion. This enables the ruthenium-iridium-titanium anode to be widely used in electrochemical applications such as chlor-alkali electrolysis, water electrolysis and wastewater treatment.

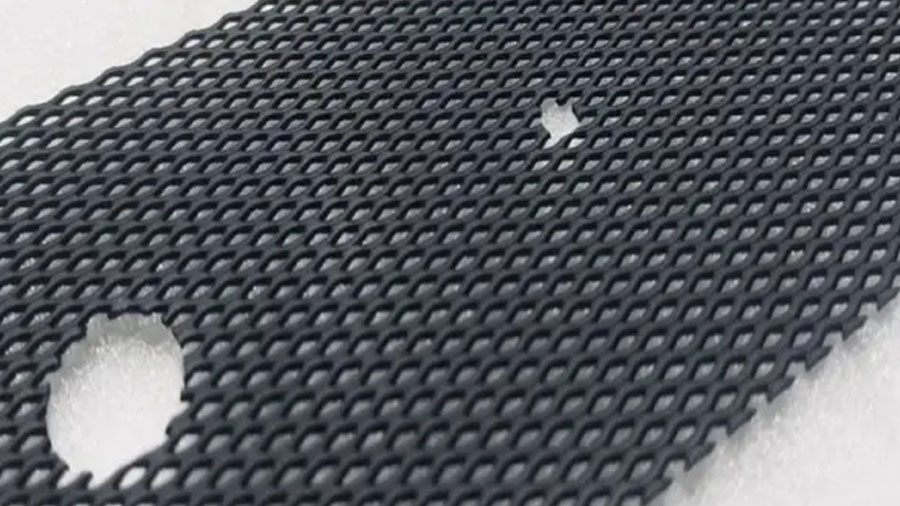

During the electrolysis process, the active coatings of ruthenium and iridium covering the surface of the ruthenium-iridium-titanium anode play a crucial role. These coatings are mainly composed of non-stoichiometric RuO₂ and TiO₂, both of which fall into the category of oxygen-deficient oxides. In fact, it is these non-stoichiometric oxides that actually serve as the activation centers for chlorine discharge, and the greater their content is, the better the activity exhibited by the anode will be.

On the anode, hydroxide ions (OH⁻) will be oxidized and converted into oxygen (O₂) and water (H₂O) with the help of electron transfer. During this conversion process, the electric current passes through the anode. After electrons flow out of the anode and enter the electrolyte, they combine with water molecules to form hydroxide ions, and then the corresponding oxidation reaction occurs on the surface of the anode.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.