_

lr MMO Anode

Operation and Maintenance Instruction

- The Iridium Mixed Metal Oxide coated Ti anodes (hereafter called lr MMO coated Ti anodes), whilst robust to the recommended electrolysis conditions.

- Oil or grease contamination of the lr MMO coating must be avoided.

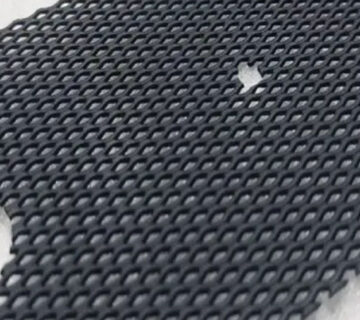

- The lr MMO coating is a porous, relatively high surface area ceramic coating,in order to provide good electrochemical characteristics. The lr MMO can easily be scratched or damaged if hard or sharp objects are rubbed or knocked against it.

a.The lr MMO coated surface must not be rested directly onto a metallic surface.

Use a protected soft covering of paper or plastic material on top of the hard surface.

b.The lr MMO surface must not be dragged over, or slid against any hard surface.

c.If dirt or deposits are present on the lr MMO coating, never attempt to clean by abrasive mechanical means. For example never clean by wire brushing, sanding or emery paper or by high-pressure water jets. - When the Ti anodes are removed from the cell, they should immediately be thoroughly flushed with water in order to prevent from acid attack as the electrolyte dries out on the surface and the acid concentration increases.

- Ti anodes, which require storage for longer periods should be carefully wrapped,

for example in air filled protective plastic wrapping material, to avoid scratch damage, dirty etc. to the lr MMO coating. - The application of the lr MMO coating to the active area of the Ti anode allows the current to flow from the Ti anode through the coated areas into the electrolyte, while the non-coated areas of the Ti anode remain inactive, If small areas of the lr MMO coating are mechanically damaged exposing the underlying Ti to the electrolyte, the Ti anode will continue operate satisfactorily because of the protective adherent oxide film formed as described above.

- The inter-electrode gap should be maintained at all times. Accidental short circuit between the Ti anode and the parts will cause irreversible damage to the lr MMO coating and will damage the Ti substrate. If the short circuit is severe the Ti anode will be destroyed.

- The Ti anodes should be maintained anodically polarised at any time as long as the Ti anodes are immersed in, or in direct contact otherwise with the electrolyte. If the Ti anodes are not energized, a small positive polarising voltage (residual potential) should be impressed onto the Ti anodes. This can be achieved without any significant current flow by setting the power supply to a voltage of 2 Volts between the anode and cathode connections. Ir MMO coated Ti anodes must be kept refrained from polarity reversal at any time.

- Trace impurities in the electrolyte, like for example Pb, Fe and Ba, should be carefully controlled so that no significant anodic depositions will occur. Anodic depositions blind the Ti anode surface and cause inhomogeneous anodic current distribution.

- Organic additives should not be introduced into the electrolyte. The Ir MMO coated Ti anode lifetime could be significantly reduced particularly by additives or additive oxidation products with complex forming characteristics.

__

Deposit removal from lr MMO coated Ti anodes

- Hydrochloric acid-this acid is useful for removal of rust type deposits in most forms as well as calcareous deposits. Due to its reducing properties to be used at ambient temperature only and at concentrations not higher than 10% v/v of 37% HCI in water. The immersion time should be kept to a minimum, for example 10 minutes, since Ti anodes are vulnerable to slow attack by reducing acids like hydrochloric acid. The rate of attack by hydrochloric acid can be reduced by the addition of 0.1% ferric chloride to the cleaning solution before the cleaning operation is carried out. NOTE: after cleaning with hydrochloric acid the Ti anodes must be thoroughly flushed with water and preferably be kept fully immersed in water for a minimum of 10 minutes.

- Citric acid-a 5-10% aqueous solution of citric at 40-50°C may be used for the removal of iron containing deposits. Again carefully flush the Ti anodes with water afterwards.

- Nitric acid-because nitric acid is an oxidising acid, lr MMO coating are fully resistant to nitric acid at any concentration and temperature. But high concentration and high temperature nitric acid have strong oxidising properties. Titanium substrate would create a Ti oxide layer between titanium and part coating. Ti oxide is less conductivity. So avoid put lr MMO anodes in high concentration and high temperature nitric acid. Low concentration and low temperature Immersion in dilute acid, will remove many deposits that form soluble nitrates. For example 10%, room temperature.